Antibacterial and deodorant high-water-absorbent resin and preparation method thereof

A technology of superabsorbent resin and formula, which is applied in deodorizing superabsorbent resin and its preparation, and antibacterial fields, which can solve the problems of user's physical injury and potential safety hazards, and achieve avoidance of rash, high safety and compatibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

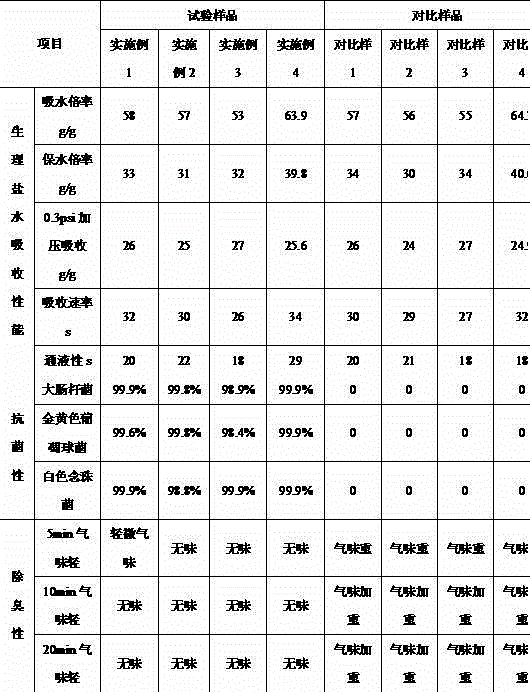

Examples

Embodiment 1

[0039] Accurately weigh 200g of acrylic acid, 60g of sodium hydroxide, 300g of deionized water, 0.1g of N,N'-methylenebisacrylamide, 0.025g of sodium sulfite, 0.025g of sodium persulfate, 15g of tea powder, polyethylene glycol dishrinkle Glyceryl ether, Polyethylene Glycol 200 are prepared according to the following steps:

[0040] 1), after mixing acrylic acid and deionized water, adding sodium hydroxide for neutralization, the degree of neutralization is 82%;

[0041] 2) Add tea powder to the reaction system, stir and mix, then oscillate ultrasonically for 10 minutes, add N,N'-methylenebisacrylamide, continue stirring for 5 minutes, then gradually raise the temperature to 60°C, then add sodium sulfite and sodium persulfate to trigger Polymerization reaction 90s, obtains gel-like polymer;

[0042] 3), granulate the gel-like polymer obtained in step 2), and dry at a temperature of 160° C. for 30 minutes to obtain a granular polymer;

[0043] 4) Mix deionized water and compos...

Embodiment 2

[0045] Accurately weigh 200g of acrylic acid, 60g of sodium hydroxide, 200g of deionized water, 2g of N,N'-methylenebisacrylamide, 0.1g of sodium sulfite, 0.1g of sodium persulfate, 30g of tea extract concentrate, polyethylene glycol di Glycidyl ether, polyethylene glycol 200 are prepared by the composite cross-linking agent 0.5g of 1:1 molar ratio configuration, then according to the following steps:

[0046] 1), after mixing acrylic acid and deionized water, adding sodium hydroxide for neutralization, the degree of neutralization is 72%;

[0047] 2) Add tea extract to the reaction system, stir and mix, then oscillate ultrasonically for 10 minutes, add N,N'-methylenebisacrylamide, continue stirring for 5 minutes, then gradually raise the temperature to 60°C, then add sodium sulfite and sodium persulfate Initiate the polymerization reaction for 90s to obtain a gel-like polymer;

[0048] 3), granulate the gel-like polymer obtained in step 2), and dry at a temperature of 160° C...

Embodiment 3

[0051] Accurately weigh 200g of acrylic acid, 60g of sodium hydroxide, 260g of deionized water, 0.1g of N,N'-methylenebisacrylamide, 0.1g of sodium sulfite, 0.1g of sodium persulfate, 60g of tea extract, polyethylene glycol di Glycidyl ether and pentaerythritol are prepared according to the molar ratio of 1:1 and 0.5 g of composite cross-linking agent is prepared according to the steps of Example 2 to obtain the superabsorbent resin of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com