Preparation method for carbon quantum dots stable in pH and strong in light emission

A carbon quantum dot and stable technology, applied in the field of carbon quantum dot preparation, can solve the problems of low fluorescence efficiency, uncontrollable microwave temperature, etc., and achieve the effects of high luminous intensity, no light blinking pH characteristics, and stable pH properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

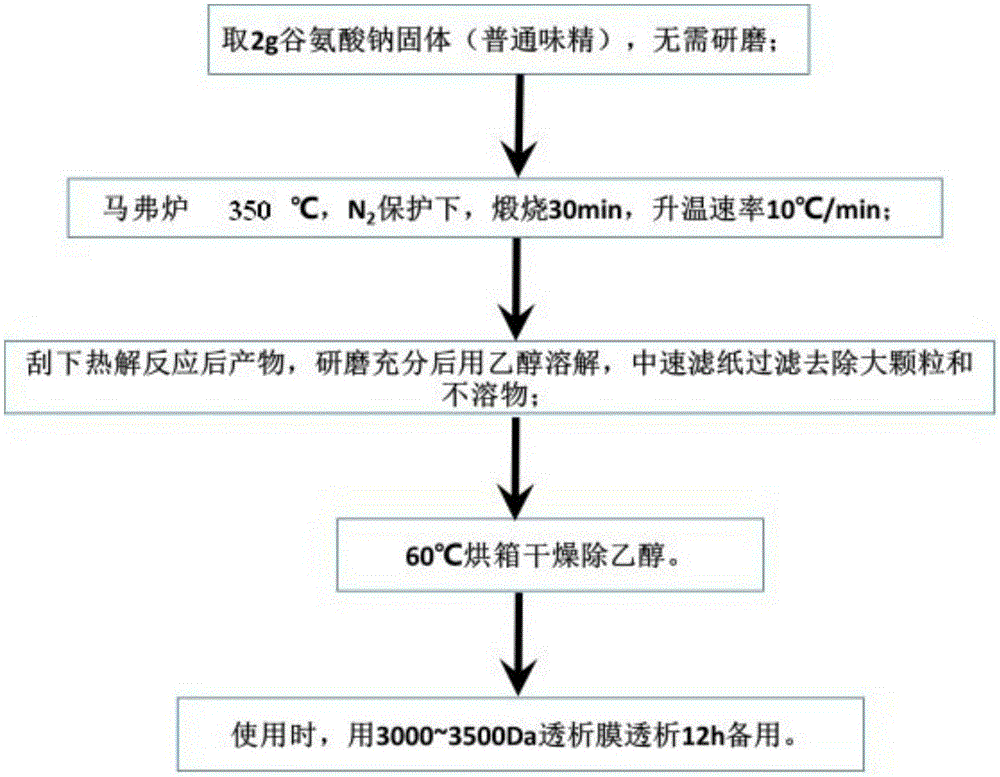

[0030] (1) Put 2g of sodium glutamate sample (general monosodium glutamate) into a small crucible without grinding, with N 2 Under protection, the calcination temperature is 350°C, the calcination time is 30min, and the heating rate is 10°C / min, and the calcination, carbonization and doping process are carried out;

[0031] (2) Scrape off the calcined product from the crucible, grind it sufficiently, dissolve it in ethanol, vibrate ultrasonically for 20 minutes, filter it with medium-speed filter paper, and dry it at 60°C for later use;

[0032] (3) Dissolve the dry product in (2) with a small amount of required solution, and dialyze with a 3000Da-3500Da dialysis membrane for 12 hours, the dialyzed fluid will be a liquid product, and the solid product will be obtained after drying.

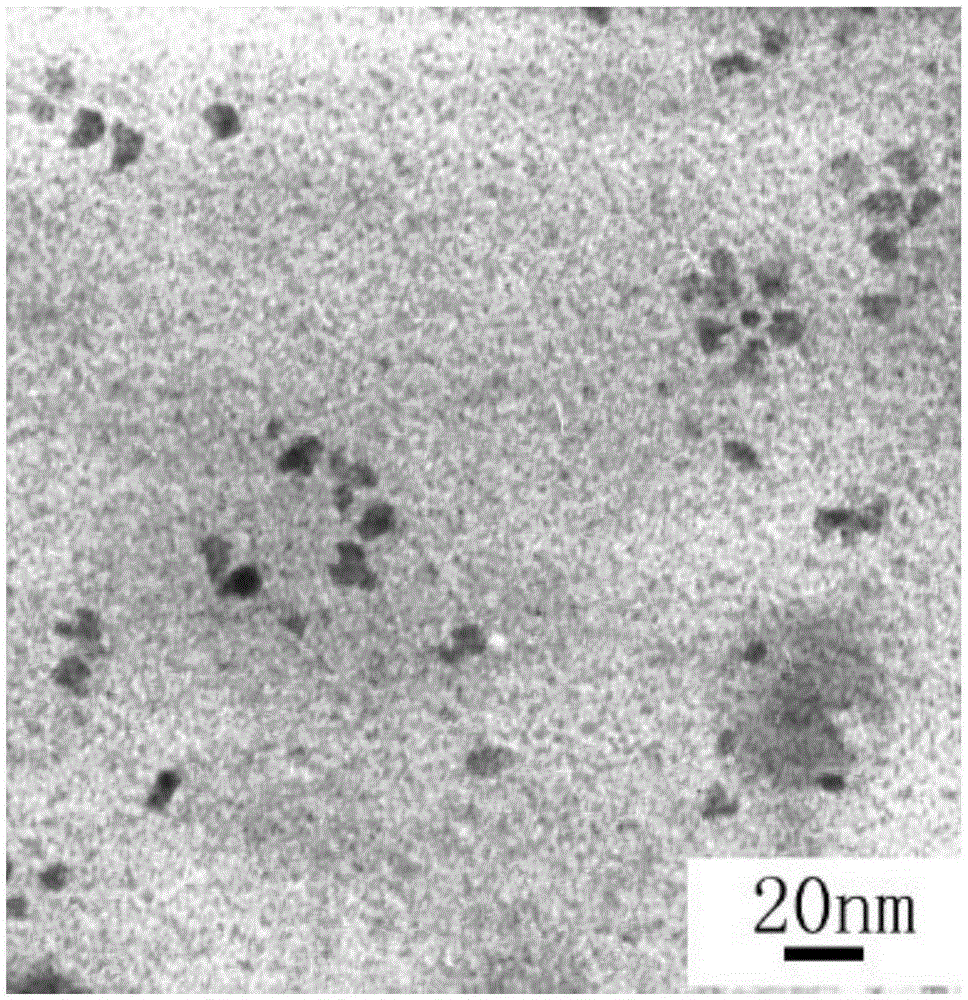

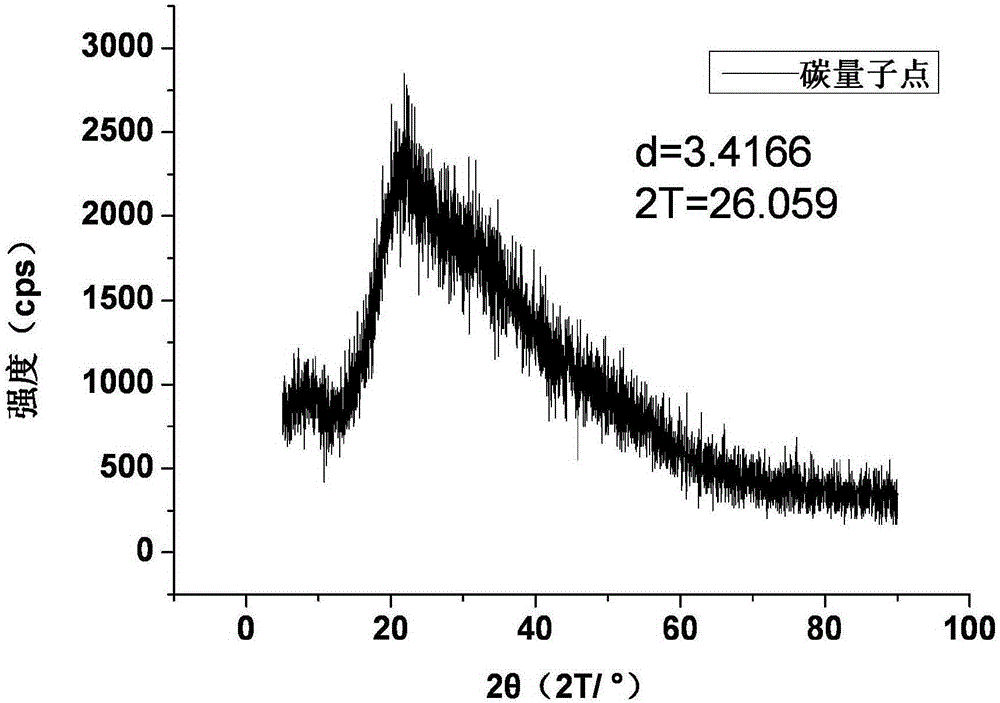

[0033] figure 1 It is the process flow diagram of the present embodiment; figure 2 The transmission electron microscope image of the inorganic non-metallic carbon particle quantum dot prepared...

Embodiment 2

[0035] (1) Put 2g of sodium glutamate sample (general monosodium glutamate) into a small crucible without grinding, the calcination temperature is 400°C, the heating rate is 10°C / min, with N 2 Under protection, the calcination time is 0.5h, 1h, 1.5h, 2h and 2.5h respectively, and the calcination carbonization and doping process are carried out;

[0036] (2) Scrape off the calcined product from the crucible, grind it sufficiently, dissolve it in water, oscillate ultrasonically for 20 minutes, filter it with medium-speed filter paper, and filter the filtrate again with a 0.22 μm water-based filter membrane.

[0037] Figure 5 For the preparation of inorganic non-metallic carbon particle quantum dots by pyrolysis, the calcination temperature is 400 ° C, with N 2 Under protection, the calcination time is 0.5h, 1h, 1.5h, 2h and 2.5h respectively ultraviolet absorption and fluorescence composite spectrum, it can be seen from the figure that under the same calcination temperature, t...

Embodiment 3

[0039] (1) Put 2g of sodium glutamate sample (general monosodium glutamate) into a small crucible without grinding, the calcination time is 30min, the heating rate is 10℃ / min, there is N 2 Under protection, the calcination temperature is 200°C, 300°C, 400°C and 500°C respectively, and the calcination carbonization and doping process are carried out;

[0040] (2) Scrape off the calcined product from the crucible, grind it sufficiently, dissolve it in water, oscillate ultrasonically for 20 minutes, filter it with medium-speed filter paper, and filter the filtrate again with a 0.22 μm water-based filter membrane.

[0041] Image 6 For the preparation of inorganic non-metallic carbon particle quantum dots by pyrolysis, the calcination time is 30min, with N 2 Under protection, the calcination temperature is 200 ℃, 300 ℃, 400 ℃ and 500 ℃ UV absorption and fluorescence composite spectrum. It can be seen from the figure that under the same calcination time, the product with the calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com