A heat treatment method for improving the magnetocaloric properties of nickel-manganese-gallium fibers

A heat treatment method, nickel-manganese-gallium technology, which is applied in the field of heat treatment of nickel-manganese-gallium fibers, can solve the problems of large lag, difficult heat dissipation, poor magnetocaloric performance and refrigeration capacity of nickel-manganese-gallium alloys, and achieve improved refrigeration capacity and magnetic properties. Can effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Specific implementation mode one: the heat treatment method for improving the magnetocaloric performance of nickel-manganese-gallium fiber in this embodiment is carried out according to the following steps:

[0030] 1. Preparation of alloy ingots:

[0031] According to Ni 50.6 mn 28 Ga 21.4 Prepare the raw materials according to the content of each element component in the mixture, and then use a vacuum melting furnace to prepare nickel-manganese-gallium alloy ingots;

[0032] 2. Preparation of alloy fibers:

[0033] A. Cut the alloy ingot into cylinders with a height of 8-10mm by wire electric discharge, immerse in acetone and ultrasonically clean the surface to remove oil, put it in a drying oven at 120-125°C for 2-3 hours and take it out;

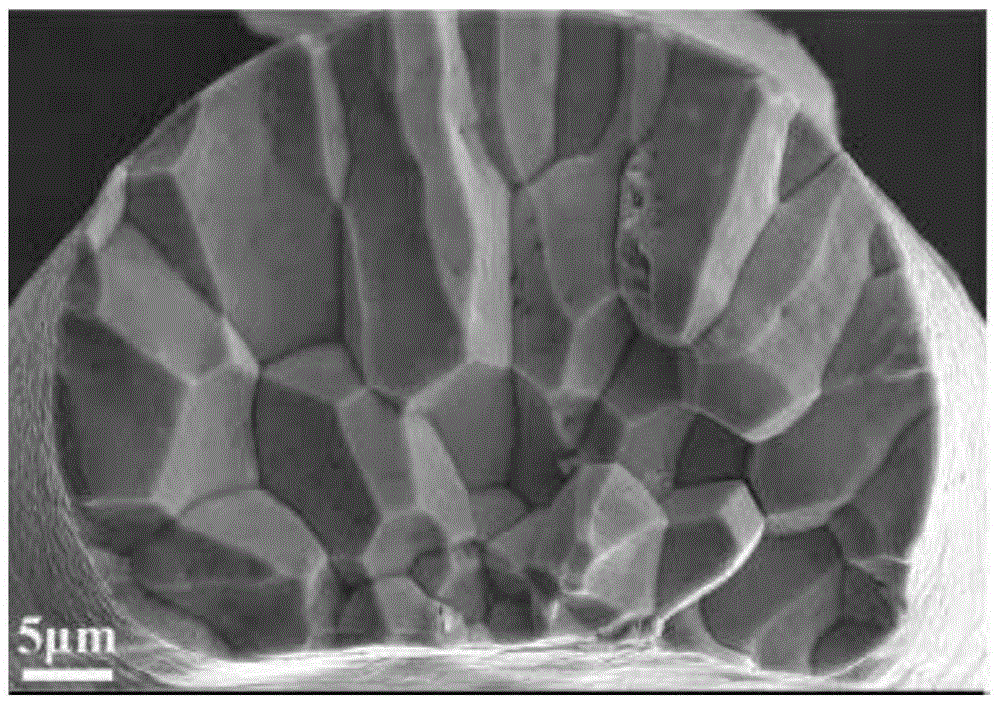

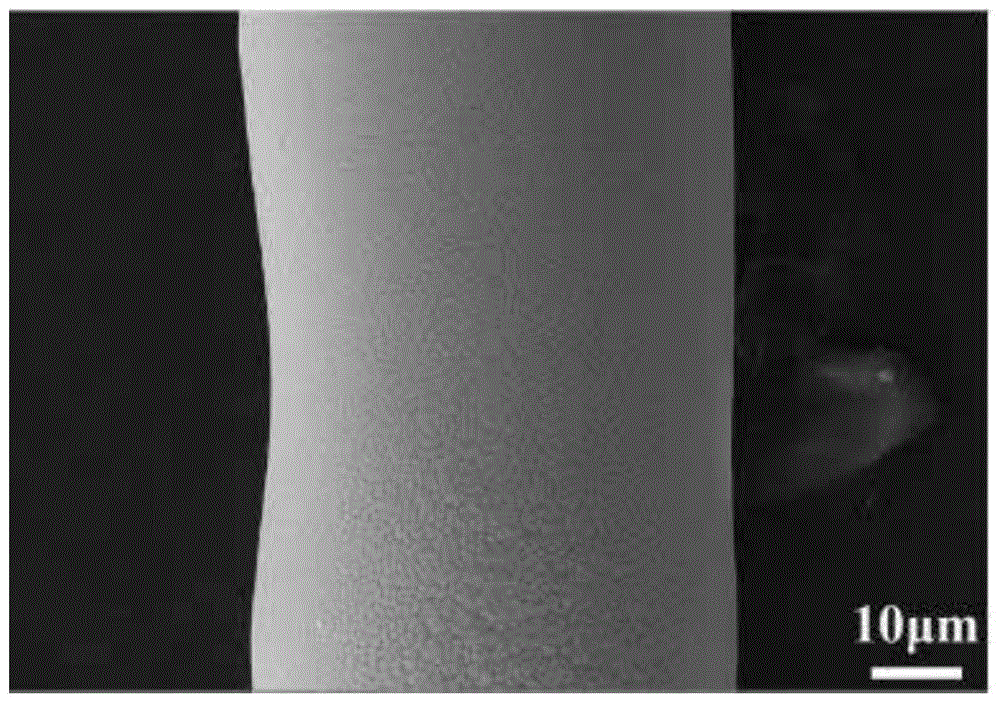

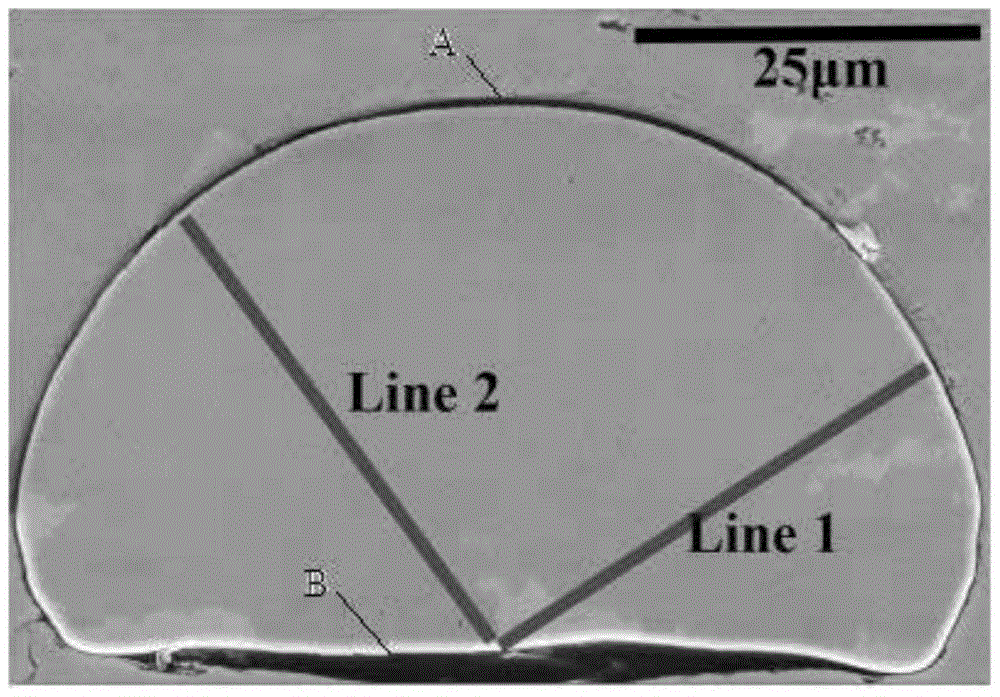

[0034]B. Put the ingot after cleaning and drying into the crucible of the melt spinning equipment, and then vacuumize the cavity to 0.5~5×10 -3 Pa filled with high-purity argon, and then vacuumed to 0.5 ~ 5 × 10 -3 Pa, and t...

specific Embodiment approach 2

[0041] Embodiment 2: This embodiment differs from Embodiment 1 in that: the diameter of the alloy fiber prepared in step 2 is 35-80 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: This embodiment is different from Embodiment 1 in that: the diameter of the alloy fiber prepared in step 2 is 50-65 μm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com