Textured structure of crystalline silicon solar cell and preparation method thereof

A technology of solar cells and crystalline silicon, which is applied in the field of solar cells and can solve problems such as unfavorable industrial production and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

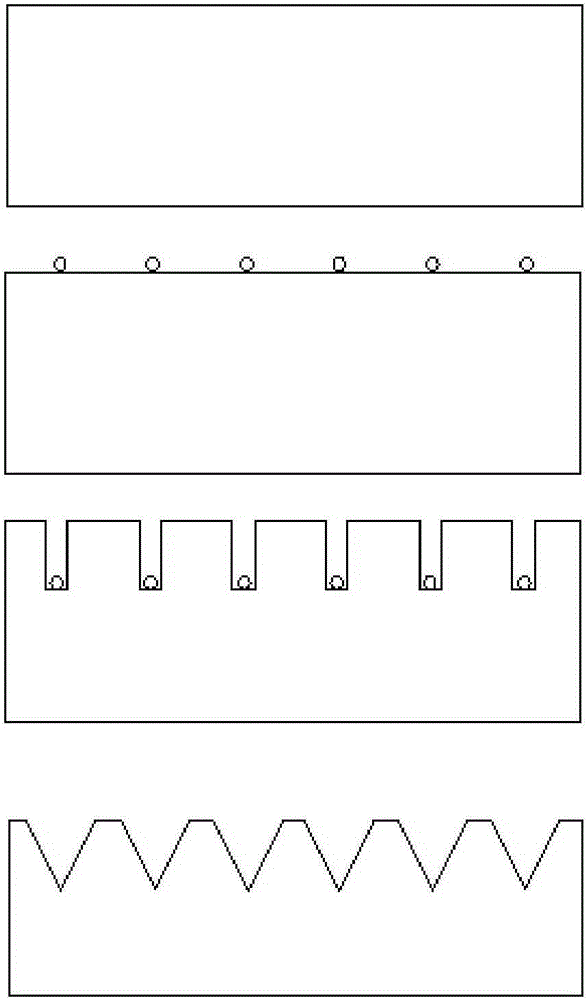

[0092] see image 3 Shown, a kind of preparation method of the textured structure of polycrystalline silicon solar cell is made up of following steps:

[0093] (1) cleaning the silicon wafer and removing the surface damage layer;

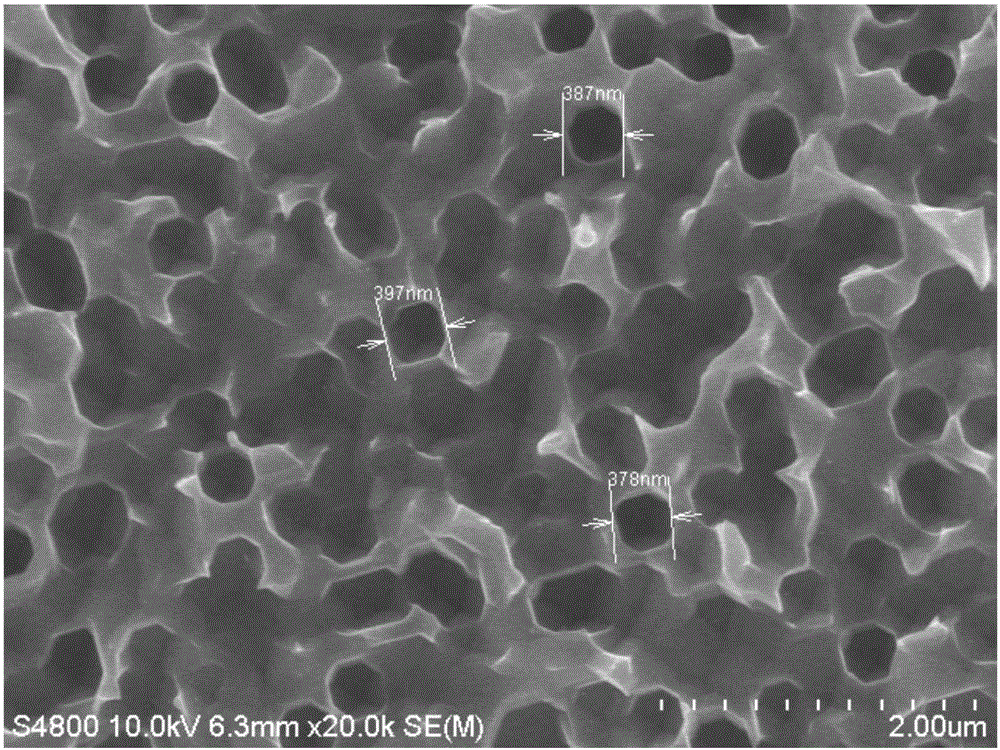

[0094] (2) Putting the above-mentioned silicon chip into a chemical etching solution containing metal ions to form a nanowire or porous silicon structure on the surface of the silicon chip; the temperature is 30° C., and the time is 2 minutes;

[0095] The metal ion is selected from silver ion;

[0096] The chemical etching solution is selected from HF and H 2 o 2 mixed solution;

[0097] Among them, the concentration of HF is 10mol / L, H 2 o 2 The concentration is 0.4mol / L;

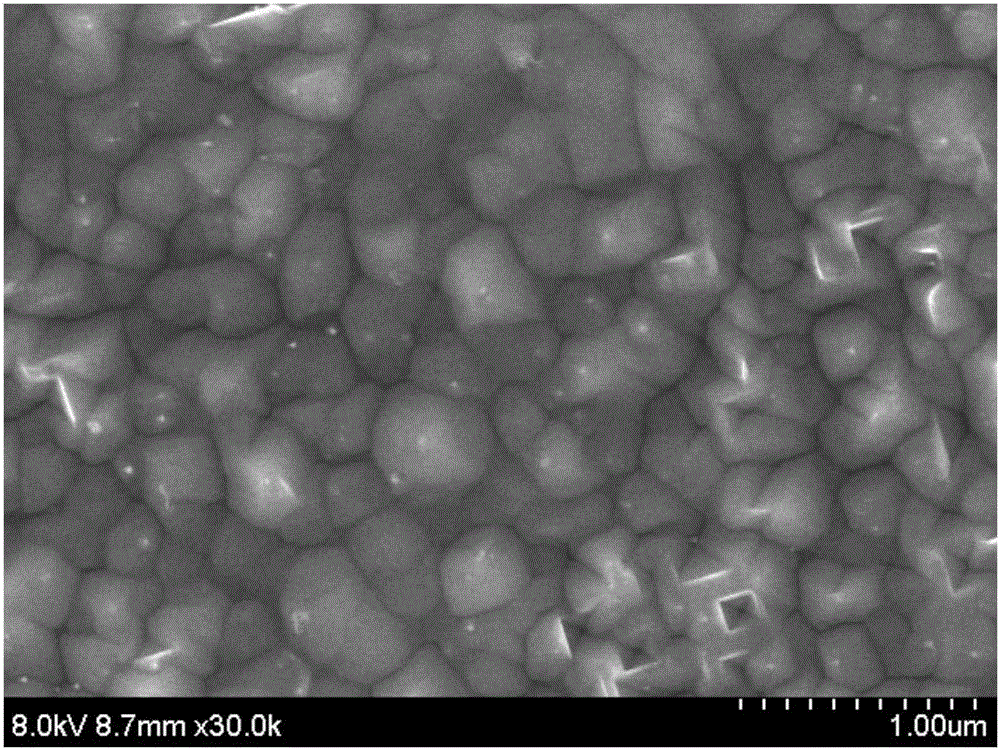

[0098] (3) Putting the above-mentioned silicon chip into the first chemical etching solution for corrective etching, so that the above-mentioned nanowire or porous silicon structure forms a nano-deep hole structure;

[0099] The first chemical etching solution is HNO 3...

Embodiment 2

[0111] see Figure 4 Shown, a kind of preparation method of the textured structure of polycrystalline silicon solar cell is made up of following steps:

[0112] (1) cleaning the silicon wafer and removing the surface damage layer;

[0113] (2) Putting the above-mentioned silicon chip into a chemical etching solution containing metal ions to form a nanowire or porous silicon structure on the surface of the silicon chip; the temperature is 30° C., and the time is 2 minutes;

[0114] The metal ion is selected from silver ion;

[0115] The chemical etching solution is selected from HF and H 2 o 2 mixed solution;

[0116] Among them, the concentration of HF is 10mol / L, H 2 o 2 The concentration is 0.4mol / L;

[0117] (3) Putting the above-mentioned silicon chip into the first chemical etching solution for corrective etching, so that the above-mentioned nanowire or porous silicon structure forms a nano-deep hole structure;

[0118] The first chemical etching solution is HNO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com