Porous electrode substrate, method for manufacturing same, and solid polymer fuel cell

A technology of a porous electrode and a manufacturing method, which is applied in the field of solid polymer fuel cells, can solve the problems of reduced power generation performance, hindered conductivity and gas diffusivity, and large interlayer structure changes, and achieves low manufacturing cost and sufficient conductivity. and the effect of gas diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0238] As short carbon fibers (A), PAN-based carbon fibers having an average fiber diameter of 7 μm and an average fiber length of 3 mm were prepared. Also, short acrylic fibers (manufactured by Mitsubishi Rayon Corporation, trade name: D122) with an average fiber diameter of 4 μm and an average fiber length of 3 mm were prepared as the oxidized fiber precursor short fibers (b). In addition, as oxidized fiber precursor short fibers fibrillated by beating, a splittable acrylic sea-island composite composed of acrylic polymer and diacetate (cellulose acetate) fibrillated by beating was prepared. Short fibers (manufactured by Mitsubishi Rayon Corporation, trade name: Vonnel M.V.P.-C651, average fiber length: 3 mm).

[0239] The production of the precursor sheet and the precursor sheet of the three-dimensional entangled structure obtained by the entanglement process were carried out by the following wet continuous papermaking method and the entanglement process by continuous press...

Embodiment 2~5

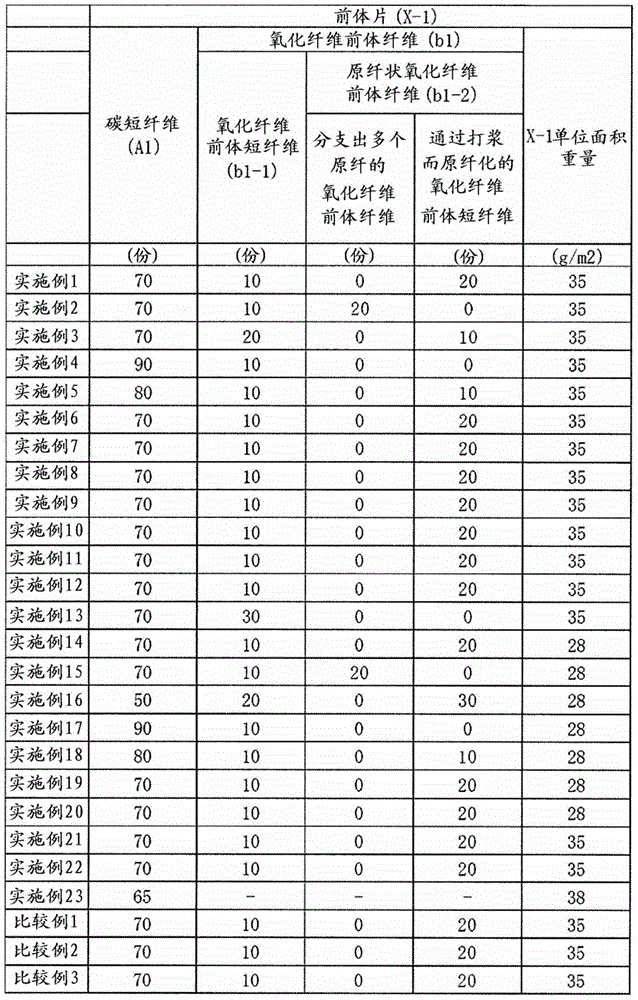

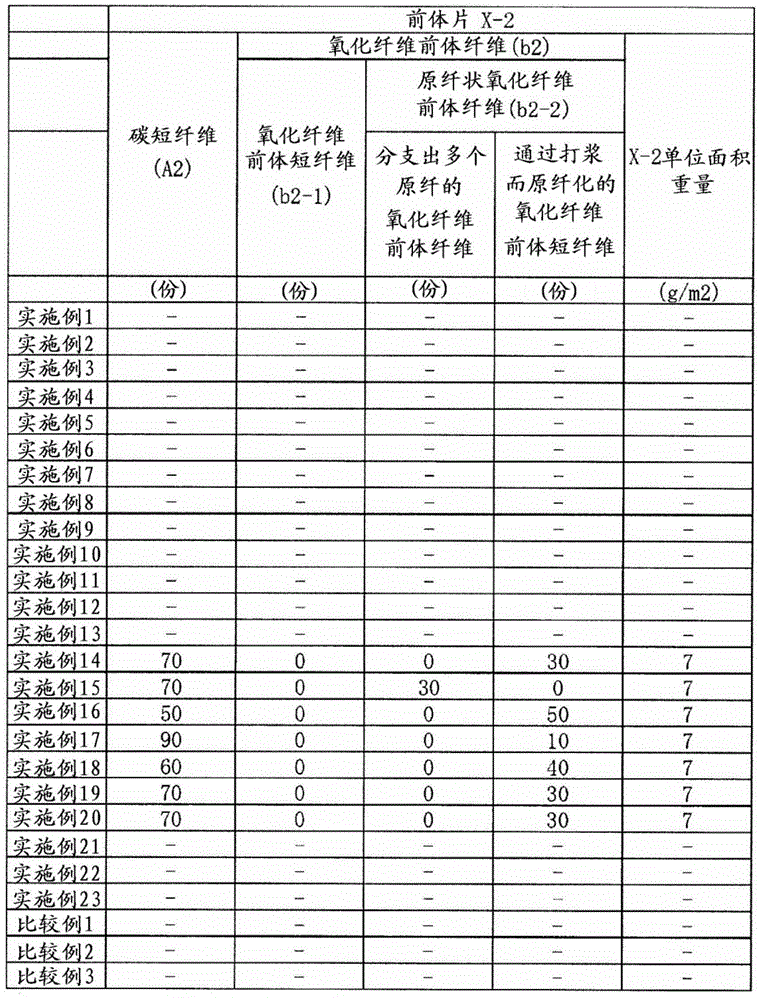

[0272] Using the dissociated pulp fibers (SA), dissociated pulp fibers (Sb-1) and dissociated pulp fibers (Sb-2) shown in Example 1, short carbon fibers (A) and oxidized fiber precursors A porous electrode substrate was obtained in the same manner as in Example 1 except that the mass ratio of short fibers and fibrillar oxidized fiber precursor fibers was set to the conditions shown in Tables 1 to 3. The obtained porous electrode substrate had no in-plane shrinkage during heat treatment, the sheet waviness was as small as 2 mm or less, and the gas permeability, thickness, and through-direction resistance were all good. Moreover, the content rate of each oxidized fiber (B) is shown in Tables 1-2. It can be confirmed that the short carbon fibers (A) dispersed in the three-dimensional structure of the obtained porous electrode substrate are bonded to each other by the oxidized fibers (B), and the short carbon fibers (A) and the oxidized fibers (B) are bonded by the carbon powder (...

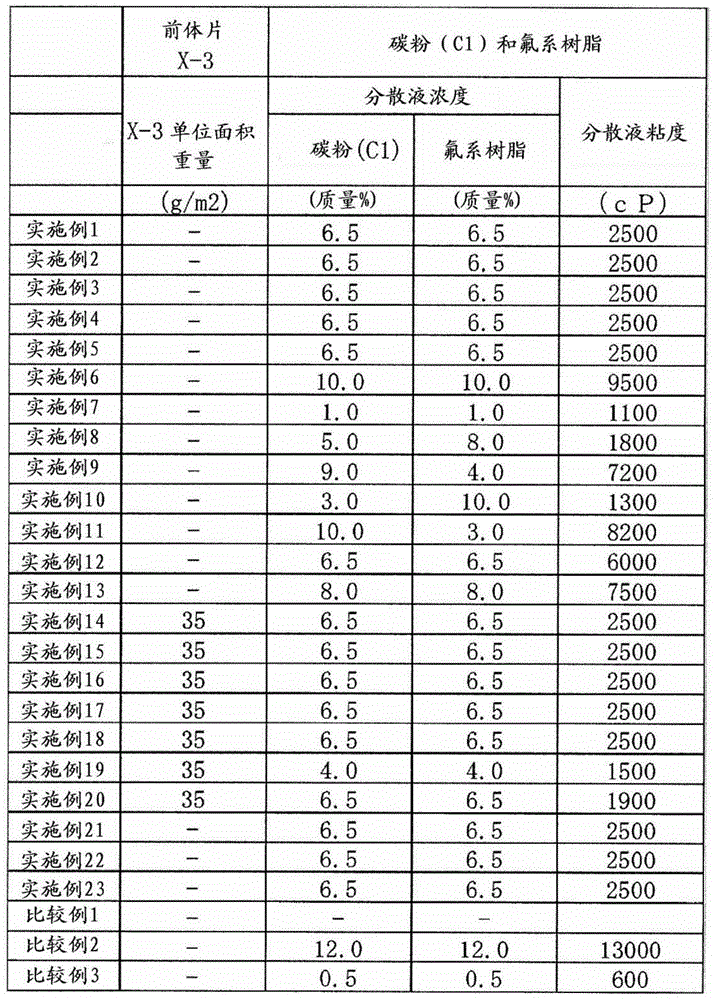

Embodiment 6~11

[0274] A porous electrode substrate was obtained in the same manner as in Example 1 except that preparation of a dispersion liquid of a mixture of carbon powder (C) and a fluorine-based resin was carried out under the conditions shown in Tables 1 to 3. Table 3 shows the viscosity of each dispersion liquid. The obtained porous electrode substrate had no in-plane shrinkage during heat treatment, the sheet waviness was as small as 2 mm or less, and the gas permeability, thickness, and through-direction resistance were all good. Moreover, the content rate of the oxidized fiber (B) was 29 mass % with respect to the whole mass of the porous electrode base material. It can be confirmed that the short carbon fibers (A) dispersed in the three-dimensional structure of the obtained porous electrode substrate are bonded to each other by the oxidized fibers (B), and the short carbon fibers (A) and the oxidized fibers (B) are bonded by the carbon powder (C) Bonded with fluororesin. Furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com