Silver catalyst for high selectivity oxidation of ethylene to prepare ethylene oxide, and use method thereof

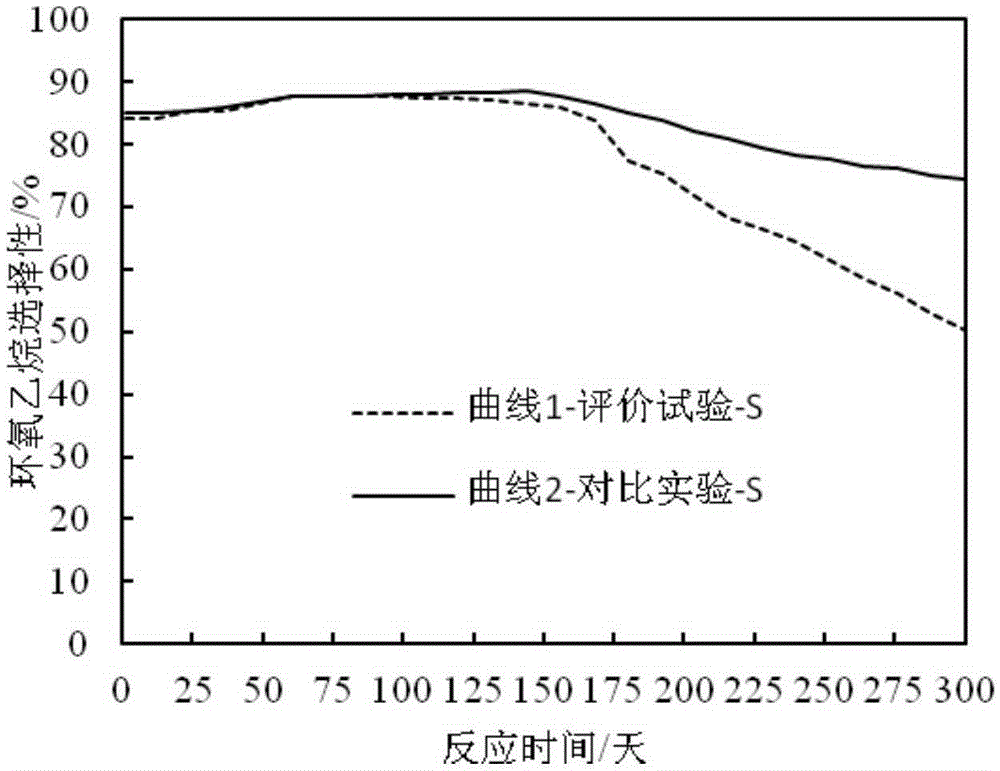

A technology for silver ethylene oxide and ethylene oxidation, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of slow deactivation, decreased selectivity, Reduce catalyst stability and other problems to achieve the effect of prolonging life, improving selectivity, and stabilizing catalyst selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

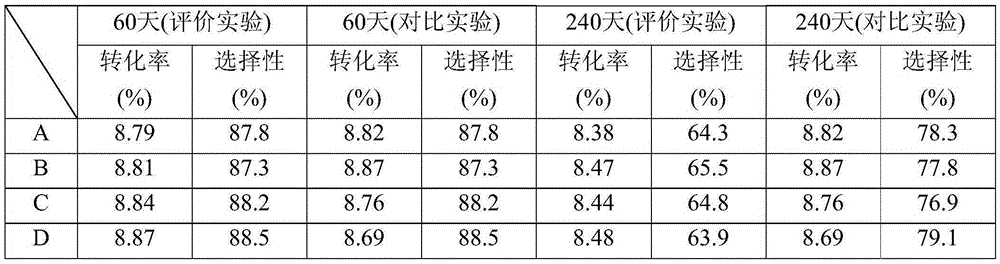

Embodiment 1

[0030] Carrier Al 2 o 3 preparation. Mix a certain amount of alumina trihydrate:alumina monohydrate mixed powder with a ratio of 2:1 and graphite powder accounting for 10% of the mass fraction of the mixed powder, and then add calcium carbonate with a mass fraction of 5% and a mass concentration of Mix and knead with 10% dilute nitric acid for 30 minutes, and finally shape it on a molding machine. After drying the molded carrier at room temperature for 8 hours, then dry it at 120°C for 4 hours. The dried carrier is finally placed in a muffle furnace Calcined at 1400° C. for 6 hours to obtain the final carrier A with a water absorption rate of 101.2%.

[0031] Weigh 23.0g of silver nitrate, dissolve 10.1g of ammonium oxalate in 112.0g of deionized water heated to 40-60°C to make an ammonium oxalate solution, slowly dissolve the weighed silver nitrate in the ammonium oxalate solution, and produce white silver oxalate precipitate . Filter the precipitate and dissolve it in a ...

Embodiment 2

[0037] Carrier Al 2 o 3 preparation. Mix a certain amount of alumina trihydrate:alumina monohydrate mixed powder at a ratio of 5:1 and graphite powder with a mass fraction of 15% of the mixed powder, and then add calcium carbonate with a mass concentration of 3% and a mass concentration of Mix and knead 20% dilute nitric acid for 30 minutes, and finally shape it on a molding machine. The molded carrier is dried at room temperature for 8 hours, and then dried at 120°C for 4 hours. The dried carrier is finally muffled at 1300°C. Calcined in the furnace for 12 hours, the final carrier B was obtained, and its water absorption rate was 89.1%.

[0038] Weigh 30.0g of silver nitrate, dissolve 15.3g of ammonium oxalate in 142.0g of deionized water heated to 40-60°C to make an ammonium oxalate solution, slowly dissolve the weighed silver nitrate in the ammonium oxalate solution, and produce white silver oxalate precipitate . Filter the precipitate and dissolve it in a mixed solutio...

Embodiment 3

[0043] Carrier Al 2 o 3 preparation. Mix a certain amount of alumina trihydrate:alumina monohydrate mixed powder with a ratio of 3:1 and graphite powder accounting for 6% mass fraction of the mixed powder, and then add calcium carbonate with a mass concentration of 8% and a mass concentration of Knead with 15% dilute nitric acid for 30 minutes, and finally shape it on a molding machine. After drying the molded carrier at room temperature for 8 hours, then dry it at 120°C for 4 hours. The dried carrier is finally placed in a muffle furnace Calcined at 1500° C. for 6 hours to obtain the final carrier C with a water absorption rate of 98.6%.

[0044] Weigh 17.0g of silver nitrate, dissolve 8.6g of ammonium oxalate in 100.0g of deionized water heated to 40-60°C to make an ammonium oxalate solution, slowly dissolve the weighed silver nitrate in the ammonium oxalate solution, and produce white silver oxalate precipitate . Filter the precipitate and dissolve it in a mixed solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com