Wavelength adjustable carbon quantum dots, preparation method and applications thereof

A technology of carbon quantum dots and wavelengths, applied in the field of carbon quantum dots and its preparation, can solve problems such as the inability to realize four-color marking, and achieve the effects of cost reduction, low toxicity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

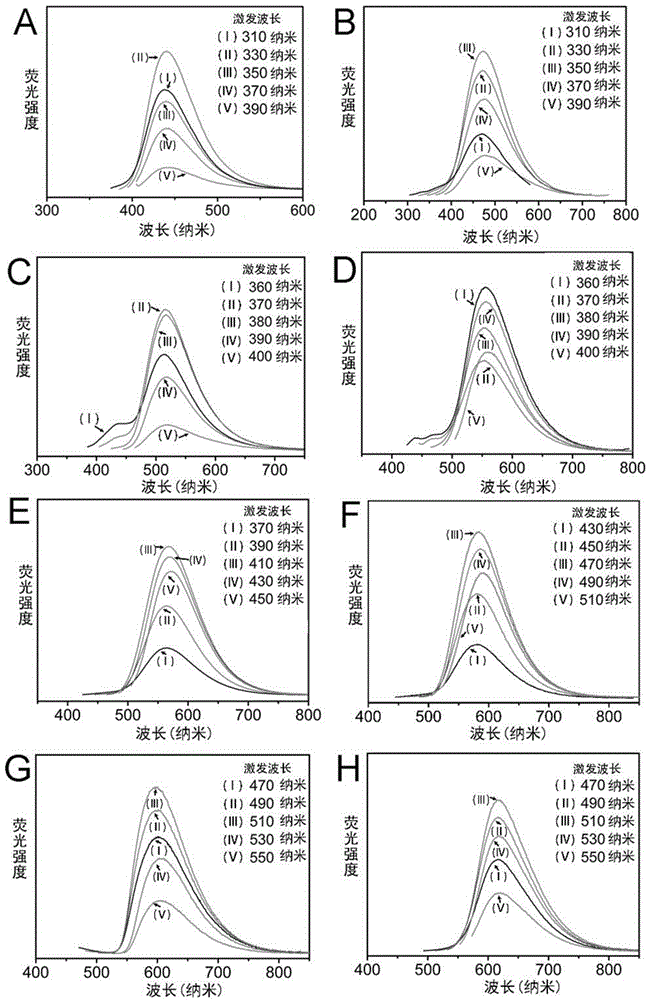

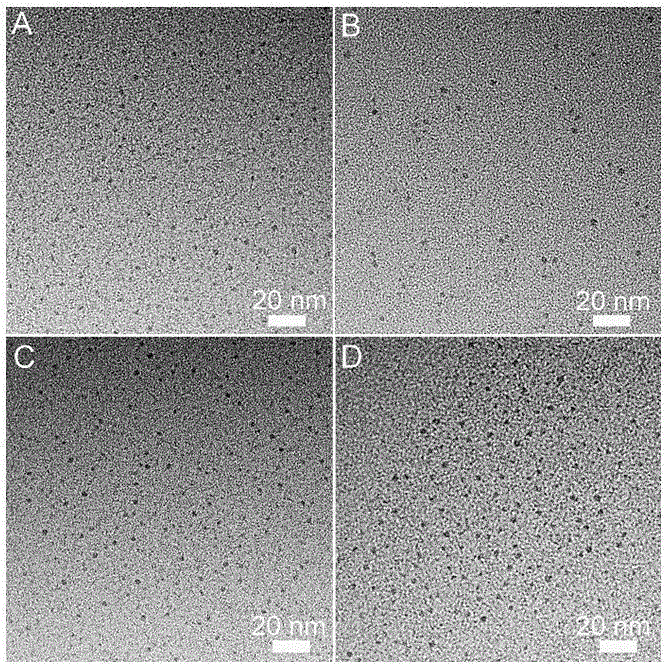

[0026] (1) Preparation of mixed solutions containing various fluorescent carbon dots

[0027] First measure 5 ml of ethanol into a 50 ml centrifuge tube, then weigh 0.2 g of urea and 0.2 g of unoxidized p-phenylenediamine into the centrifuge tube quickly, shake until completely dissolved, and form a reddish-brown solution . Then add 45 ml of deionized water, mix evenly, transfer the mixture into an autoclave (150 ml), and seal it for storage. After preheating the high temperature oven to 160 degrees Celsius, put the reaction kettle into the oven for 10 hours. After the reaction is completed, turn off the oven, open the ovens, and cool to room temperature naturally;

[0028] (2) Purification of mixed solutions containing various fluorescent carbon dots

[0029]Rotate the mixture obtained in step (1) (water bath, 65 degrees Celsius) until 3-5 ml of liquid remain, add 6-8 grams of silica gel (100-200 mesh), stir evenly, rotate again to dryness, and save . At the same time, us...

Embodiment 2

[0032] The preparation method is the same as in Example 1, but the reaction temperature is changed to 180 ° C, and other conditions remain unchanged. The emission wavelengths of the four finally obtained fluorescent carbon dots are 434, 512, 564, and 609 nanometers. The quantum yields are: 33, 12, 18, 6%, respectively.

Embodiment 3

[0034] The preparation method is the same as in Example 1, but the reaction temperature is changed to 140 degrees Celsius, and other conditions remain unchanged. The emission wavelengths of the four fluorescent carbon dots finally obtained are 452, 525, 571, and 630 nanometers. The quantum yields are: 11, 8, 5, and 2%, respectively. From the results, temperature has a significant effect on both the emission wavelength and quantum yield, especially the quantum yield, which may be because temperature plays a key role in the formation of carbon dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com