One-component organosilane modified polyether coating and preparation method thereof

A technology of silane-modified polyether and organosilane, which is applied in the field of coatings, can solve the problems of restricting the development of polyurethane waterproof coatings, difficulty in meeting the requirements of exposure, and difficulty in improving weather resistance, and achieves strong deformation adaptability, excellent weather resistance, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The one-component organic silane modified polyether coating of this embodiment is made up of the following mass percent: silane modified polyether 35%, nanometer calcium carbonate 10%, rutile type titanium dioxide 10%, heavy calcium 25%, Tinuvin-928 0.2%, Tinuvin-770 0.2%, Irganox-245 0.1%, Bayer 264 0.1%, plasticizer 10%, vinyltrimethoxysilane 0.5%, N-(β-aminoethyl)-γ-aminopropyl Trimethoxysilane 0.5%, drier 0.4%, ISOPAR-L 6%, ISOPAR-H 2%.

[0034] The silane-modified polyether described in the present embodiment is the S303H of Japan KANEKA company; The nano-calcium carbonate is the SP of Japan Takehara Company; The rutile type titanium dioxide is the R-706 of U.S. Dupont; Mesh heavy calcium (moisture content≤0.5%); The plasticizer is a difunctional polyether polyol with a molecular weight of 2000 on the market; The drier is U-220H (organic tin drier) ).

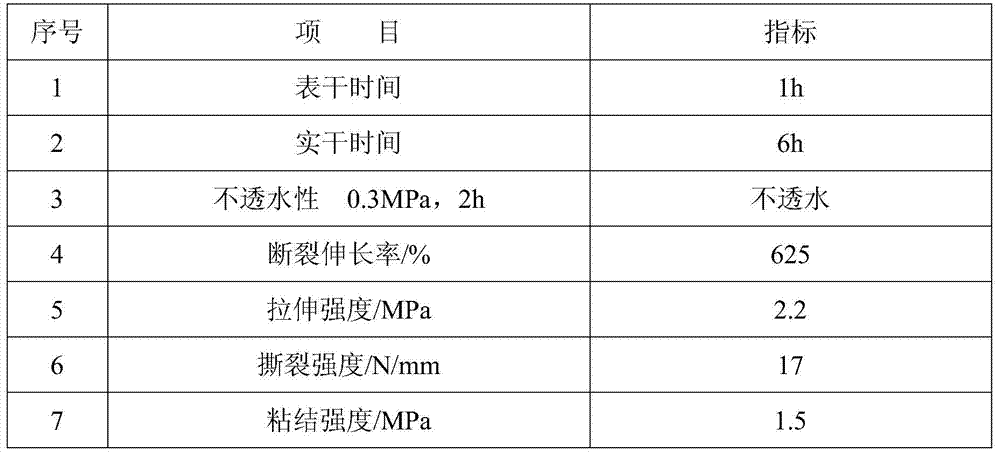

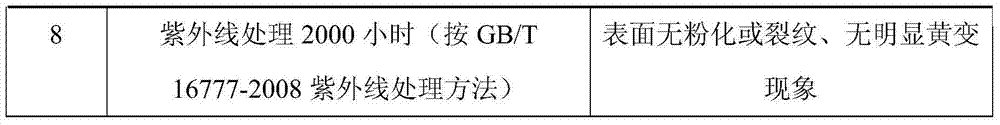

[0035] Its properties of the one-component organosilane modified polyether coating described in the present emb...

Embodiment 2

[0051] The one-component organosilane-modified polyether coating in this embodiment is composed of the following mass percentages: 20% silane-modified polyether a, 10% silane-modified polyether b, 15% nanometer calcium carbonate, 10% rutile titanium dioxide , heavy calcium 22%, Tinuvin-11300.1%, Tinuvin-326 0.2%, Tinuvin-770 0.1%, Tinuvin-292 0.2%, Irganox-245 0.3%, plasticizer 15%, vinyltrimethoxysilane 0.4%, N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane 0.4%, drier 0.3%, ISOPAR-E 3%, ISOPAR-G 3%.

[0052] The silane-modified polyether a described in the present embodiment is the S303H of Japan KANEKA company; The silane-modified polyether b described in the present embodiment is the S203H of Japan KANEKA company; Described nano-calcium carbonate is the SP of Japan Takehara Company; Titanium dioxide is the R-706 of U.S. DuPont; the heavy calcium is 3000 mesh heavy calcium (without surface treatment, water content≤0.5%); the plasticizer is the difunctional polyether polyol of...

Embodiment 3

[0063] The one-component organosilane modified polyether coating of this embodiment is made up of the following mass percentage: silane modified polyether 25%, nanometer calcium carbonate 13%, rutile type titanium dioxide 15%, 1250 order talcum powder 28%, Tinuvin -11300.1%, Tinuvin-928 0.2%, Tinuvin-292 0.3%, Bayer 264 0.5%, plasticizer 5%, vinyltrimethoxysilane 0.2%, N-(β-aminoethyl)-γ-aminopropyl Trimethoxysilane 2%, drier 0.7%, ISOPAR-V 5%, Idemitsu LX 5%.

[0064] The silane-modified polyether described in this embodiment is S203H of Japan KANEKA Company; the nano-calcium carbonate is the SP of Japan Takehara Company; the titanium dioxide is R-706 of U.S. Dupont; Talc powder (moisture content ≤ 0.2%); the plasticizer is a trifunctional polyether polyol with a molecular weight of 5000 on the market; the drier is U-220H from Nitto Kasei.

[0065] Its properties of the one-component organosilane modified polyether coating described in the present embodiment are as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com