Dampness-heat-resistant high-reliability epoxy conductive silver adhesive as well as preparation method and application thereof

A conductive silver glue, reliable technology, used in epoxy resin glue, conductive adhesive, adhesive and other directions, can solve the problems of complex synthesis process, chip and bracket peeling, and easy damage of electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

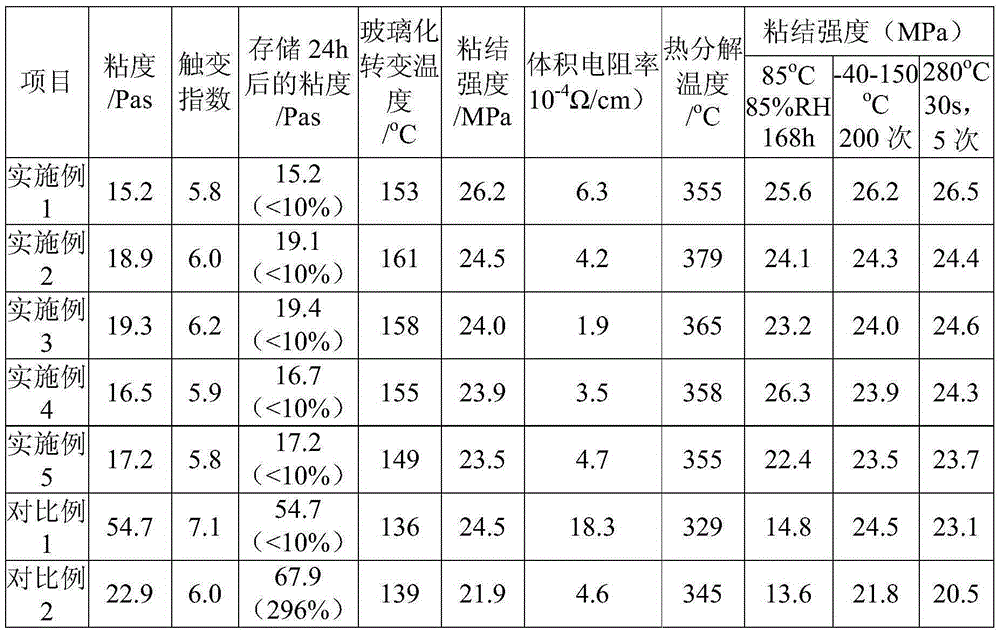

Examples

Embodiment 1

[0074] This embodiment provides a method for preparing an epoxy conductive silver glue with high resistance to heat and humidity, wherein the preparation method includes the following steps:

[0075] Sequentially weigh bisphenol F epoxy resin: 12 parts by weight, hyperbranched polyester modified toughening agent: 2 parts by weight, triallyl isocyanurate: 4.0 parts by weight, epoxy-modified acrylate Compound: 1 part by weight, trimethylolpropane glycidyl ether: 3.0 parts by weight, and mix them uniformly in a high-speed mixer to obtain a mixture A;

[0076] Then add 2-methyl-4-ethylimidazole to the mixture A obtained: 0.7 parts by weight, dicyandiamide: 1.0 parts by weight, benzoyl peroxide: 0.5 parts by weight, polyamide wax: 0.3 parts by weight , KH-560 silane coupling agent: 0.3 parts by weight, TEGO-245: 0.2 parts by weight, continue to mix it uniformly in a high-speed mixer to obtain conductive silver colloid matrix B;

[0077] Finally, 75 parts by weight of silver powder...

Embodiment 2

[0079] This embodiment provides a method for preparing an epoxy conductive silver glue with high resistance to heat and humidity, wherein the preparation method includes the following steps:

[0080] Sequentially weigh bisphenol F-type epoxy resin: 12 parts by weight, epoxy-terminated polybutadiene rubber: 2 parts by weight, triglycidyl isocyanurate: 5.0 parts by weight, epoxy-modified acrylate compound: 2.0 parts by weight, and in a high-speed mixer, it is mixed uniformly to obtain mixture A;

[0081] Then add dicyandiamide to the obtained mixture A: 1.0 parts by weight, 2-methyl-4-ethylimidazole: 0.7 parts by weight, benzoyl peroxide: 0.5 parts by weight, hydrogenated castor oil: 0.3 parts by weight , KH-560 silane coupling agent: 0.3 parts by weight, NP-10: 0.2 parts by weight, continue to mix it uniformly in a high-speed mixer to obtain conductive silver colloid matrix B;

[0082] Finally, 76 parts by weight of silver powder are added in batches to the conductive silver c...

Embodiment 3

[0084] This embodiment provides a method for preparing an epoxy conductive silver glue with high resistance to heat and humidity, wherein the preparation method includes the following steps:

[0085] Weigh successively bisphenol A epoxy resin: 12 parts by weight, epoxy-terminated polybutadiene rubber: 2 parts by weight, triallyl isocyanurate: 4.0 parts by weight, epoxy-modified acrylate Compound: 1.0 parts by weight, and uniformly mix it in a high-speed mixer to obtain mixture A;

[0086] Then add dicyandiamide to the obtained mixture A: 1.0 parts by weight, 1-cyanoethyl-2-ethyl-4-methylimidazole: 0.7 parts by weight, benzoyl peroxide: 0.5 parts by weight, gas phase Silicon dioxide: 0.3 parts by weight, KH-550 silane coupling agent: 0.3 parts by weight, Span80: 0.2 parts by weight, continue to mix it uniformly in a high-speed mixer to obtain conductive silver colloid matrix B;

[0087] Finally, 78 parts by weight of silver powder are added in batches to the conductive silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com