Manufacturing method for hybrid heterojunction solar cell

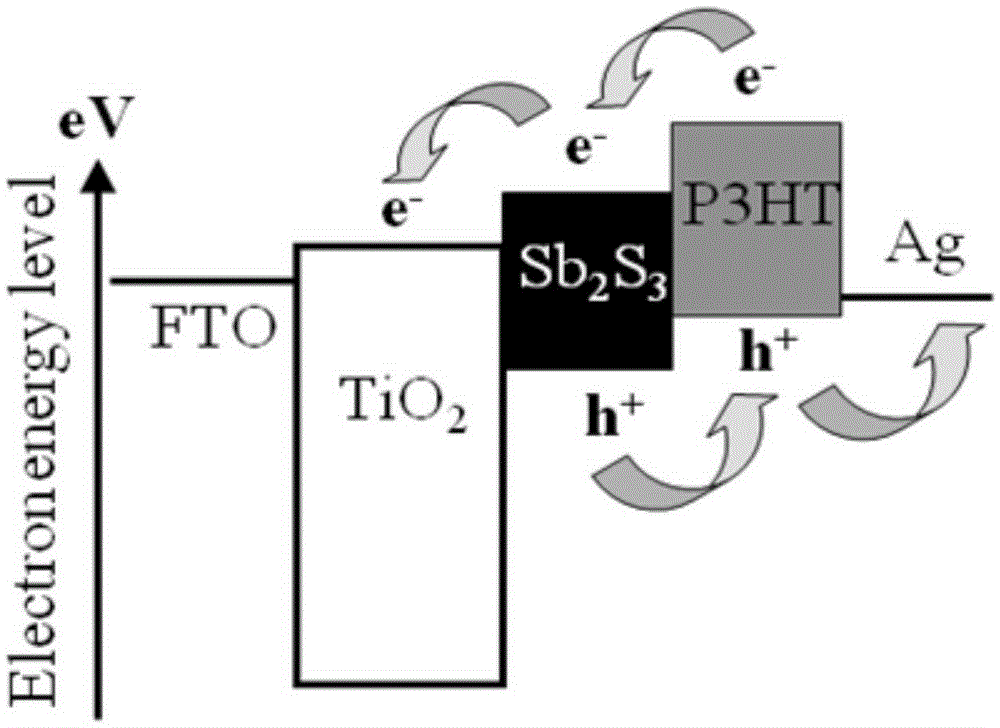

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low photoelectric conversion efficiency, narrow spectral response range, and low utilization rate of sunlight of solar cells, and achieve environmentally friendly use, The principle is scientific and reasonable, and the effect of improving the photoelectric conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the hybrid heterojunction solar cell involved in this example includes preparing a conductive glass substrate, preparing an ordered TiO 2 Nanorod array film layer, preparation of antimony trisulfide (Sb 2 S 3 ) nano film layer, prepare 3-hexylthiophene (P3HT) nano film layer and prepare silver (Ag) film electrode five steps:

[0025] (1) Preparation of conductive glass substrate: Cut the FTO transparent conductive glass with a thickness of 0.8mm into a square with a size of 1cm×1cm, ultrasonically clean it with acetone, ethanol and deionized water in turn, and dry it with nitrogen to complete the conductive glass substrate preparation of

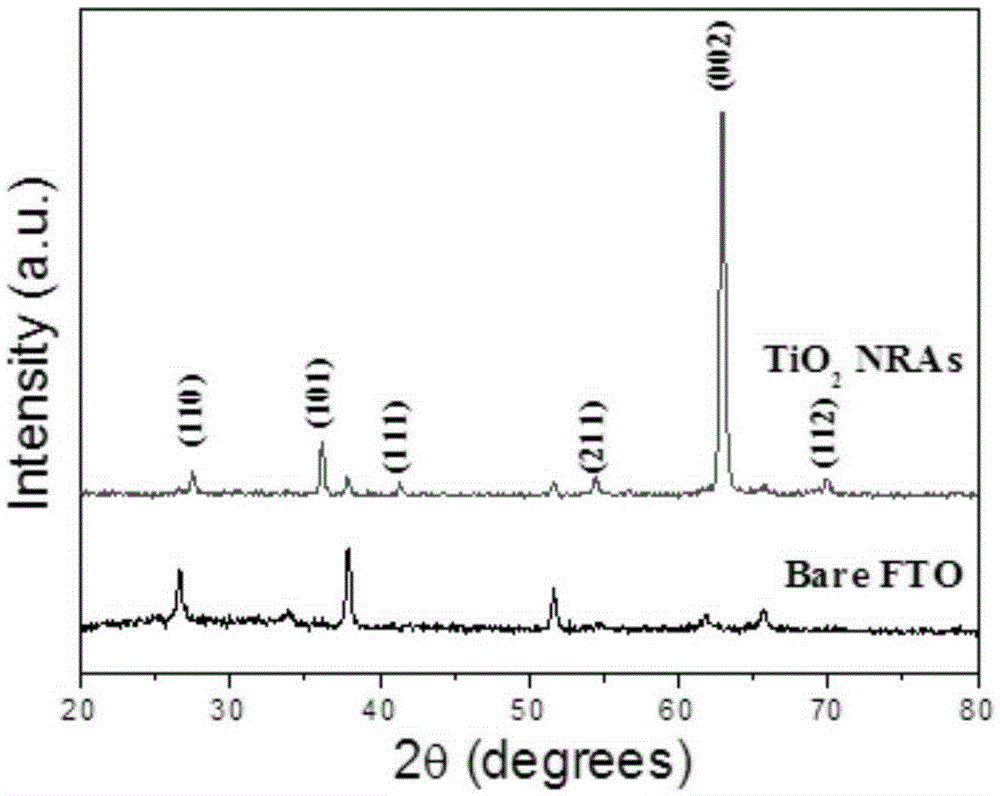

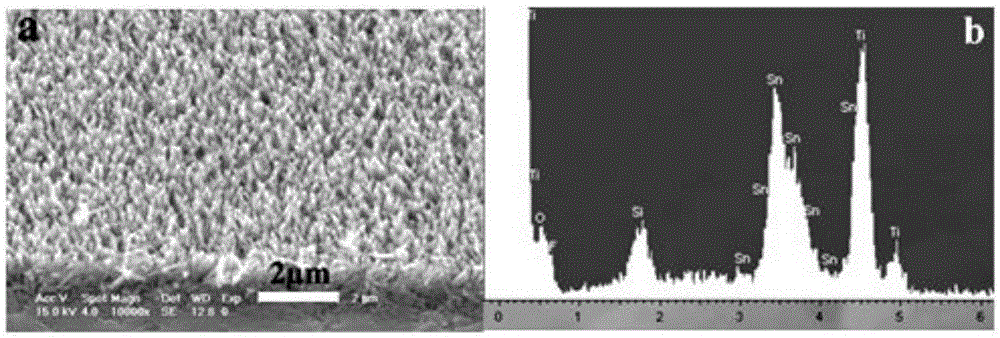

[0026] (2) Preparation of ordered TiO 2 Nanorod array film layer: Mix 0.2ml of TTIP, 10ml of 37% hydrochloric acid (HCl) aqueous solution and 20ml of deionized water under magnetic stirring to obtain 30ml of TiO 2 precursor solution, the conductive glass substrate and TiO 2 The precursor solution was pla...

Embodiment 2

[0034] The process steps of this embodiment are the same as those of Example 1, except that the thickness of the FTO transparent conductive glass in step (1) is 2 mm, and the size cut into a square of 4 × 4 cm, the prepared ordered TiO 2 The nanorod array film layer is uniformly and orderly distributed, with a high density, a diameter of 75-90nm, and a length of 0.8-1.1μm

Embodiment 3

[0036] The process step of this embodiment is the same as that of Example 1, except that the volume of TTIP in step (2) is 0.4ml, and the volume of hydrochloric acid (HCl) aqueous solution of 37% by mass is 15ml, and the prepared ordered TiO 2 The film layer of the nanorod array is evenly and orderly distributed, the density is small, the diameter is 80-95nm, and the length is 0.9-1.2μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com