Method for producing forage-use egg yolk color enhancer by means of fruit and vegetable processing waste

A waste and feeding technology, applied in the field of egg yolk color enhancer for feeding, to achieve the effect of increasing the average egg weight, increasing the price of egg yolk, realizing circular economy and sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1. In the first step, orange peel, red bayberry core, bean dregs, camellia oleifera husk, and palm dinoflagellate are dried or dried, and the water content is 10-13%, and they are respectively pulverized into 60-80 mesh coarse powder;

[0022] In the second step, the raw materials are weighed in parts by weight (formula 1): 25 parts of bayberry cores, 28 parts of bean dregs, 4 parts of Camellia oleifera husks, 3.6 parts of Paleopsis dinoflagellates, and 7 parts of additives. Auxiliary agent is microcrystalline cellulose: hydroxypropyl-beta-cyclodextrin: xylitol=1.2:2.9:2.1; After mixing the coarse powder of each raw material, it is evenly mixed with the auxiliary agent;

[0023] The third step is to process the raw materials mixed in the second step with a high-energy vibrating mill. The cooling cycle water temperature is 19-21 ° C, the frequency is 16 Hz, and the steel rod acceleration is 8-9 g. The processing time is 15-30 minutes, and then the machine is st...

Embodiment 2

[0024] Example 2, raw material parts by weight (formula 2) are: 17 parts of orange peel powder, 27 parts of bean dregs, 24 parts of red bayberry kernel powder, 3 parts of Camellia oleifera husk, 3.6 parts of brown dinoflagellate powder, 7 parts of additives, preparation method With embodiment 1.

Embodiment 3

[0025] Example 3, parts by weight of raw materials (formula 3): 19 parts of orange peel powder, 29 parts of bean dregs, 26 parts of red bayberry kernel powder, 5 parts of Camellia oleifera husk, 3.6 parts of P. Example 1.

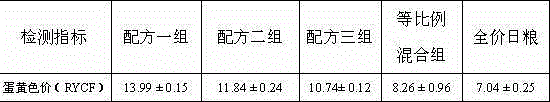

[0026] Method of use: add 2-3% of the product of the present invention to the full-price diet of laying hens, and use it continuously for more than 3 days to significantly increase the value of egg yolk and have no adverse effects on other physiological indicators of laying hens. And can increase egg production rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com