Method for preparing iron and cerium compound by means of ultrasonic infiltration and application of method in fenton-like water treatment

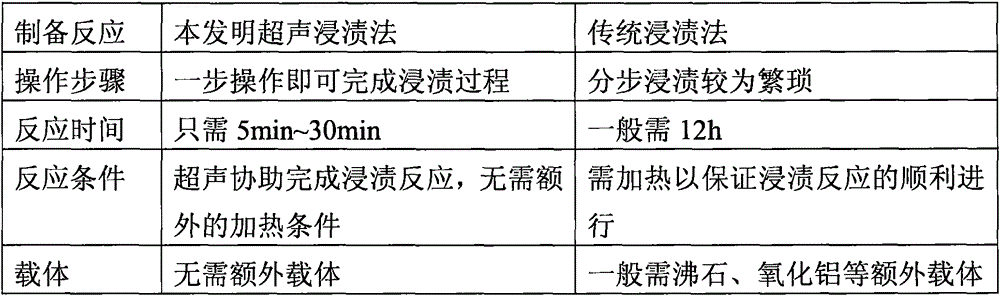

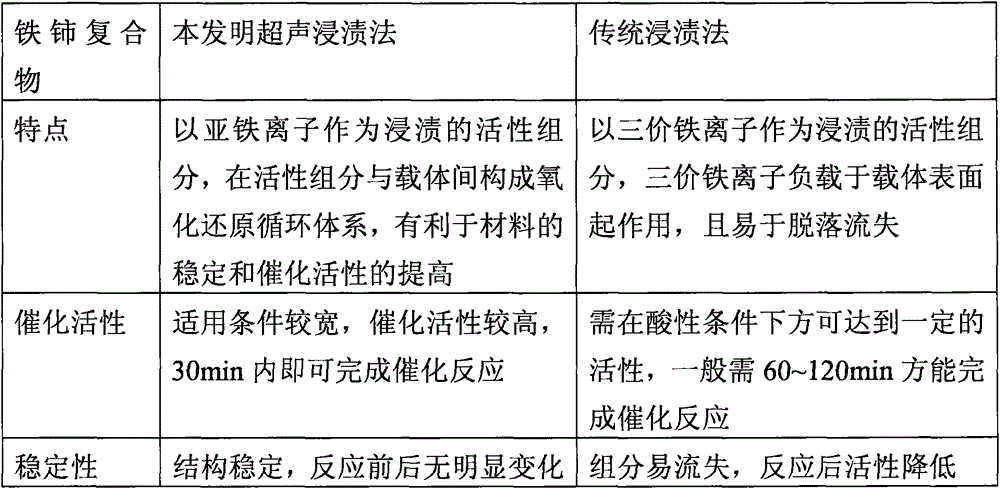

A technology of ultrasonic impregnation and composite oxides, which is applied in natural water treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of easy loss of catalyst active components, unstable structure and low activity. , to achieve the effect of short immersion reaction time, easy control of reaction conditions and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

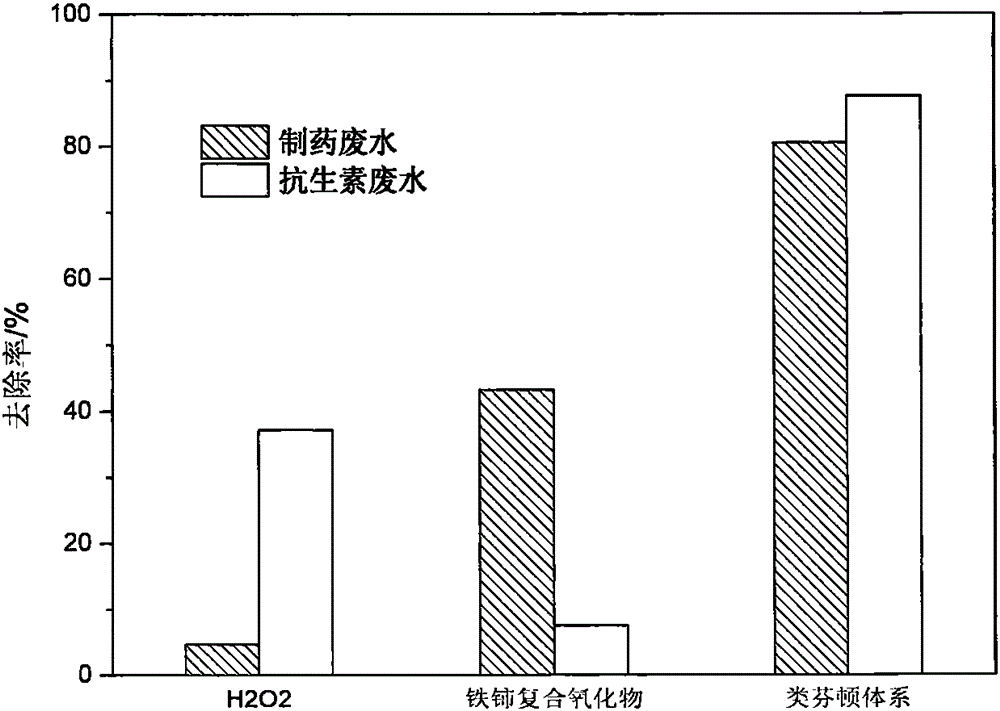

[0018] Composition of simulated pharmaceutical wastewater: distilled water 100mL and diclofenac sodium 2mg.

[0019] Add 0.1g of iron-cerium complex to the simulated pharmaceutical wastewater, add hydrogen peroxide at a concentration of 100mmol / L, adjust the initial pH value to 5, and react for 20 minutes, filter the reacted solution through a 0.22 micron PTFE filter head, and collect the filtrate for use The concentration of diclofenac sodium was determined by high performance liquid chromatography and the removal rate was calculated.

[0020] High-performance liquid chromatography detection conditions: US Waterse2695 high-performance liquid chromatography, equipped with a 250mm×4.6mm C18 reversed-phase column and an ultraviolet detector. The ultraviolet detection wavelength is 275nm; elution conditions: the mobile phase is composed of glacial acetic acid aqueous solution and acetonitrile with a concentration of 0.05mol / L, the volume ratio is 30%:70%, the flow rate is 1ml / min...

Embodiment 2

[0022] Composition of simulated antibiotic wastewater: distilled water 100mL and amoxicillin 2mg.

[0023] Add 0.1g of iron-cerium complex to the simulated antibiotic wastewater, add hydrogen peroxide at a concentration of 100mmol / L, adjust the initial pH value to 5, and react for 20 minutes, filter the reacted solution through a 0.22 micron PTFE filter head, and collect the filtrate for use The concentration of amoxicillin was determined by high performance liquid chromatography and the removal rate was calculated.

[0024] High-performance liquid chromatography detection conditions: US Waterse2695 high-performance liquid chromatography, equipped with a 250mm×4.6mm C18 reversed-phase column and an ultraviolet detector. The ultraviolet detection wavelength is 225nm; elution conditions: the mobile phase is composed of ultrapure water and methanol at a concentration of 90%:10%, the flow rate is 1ml / min, the injection volume is 10 μL, and the column temperature is 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com