Method and device for combined electrochemical cathode and anode treatment of wastewater

A combined treatment, cathode and anode technology, applied in the direction of electrochemical water/sewage treatment, etc., can solve the problems of reducing the effect of wastewater treatment, the difficulty of treating industrial wastewater, and the transfer of pollutants, avoiding secondary pollution problems, and being easy to control and measure. , the effect of biochemical enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method and device for electrochemical cathode and anode combined wastewater treatment of the present invention will be further described below with reference to the accompanying drawings and specific examples. Those skilled in the art should understand that the examples listed are only for better understanding and realization of the present invention, and are not intended to limit the present invention.

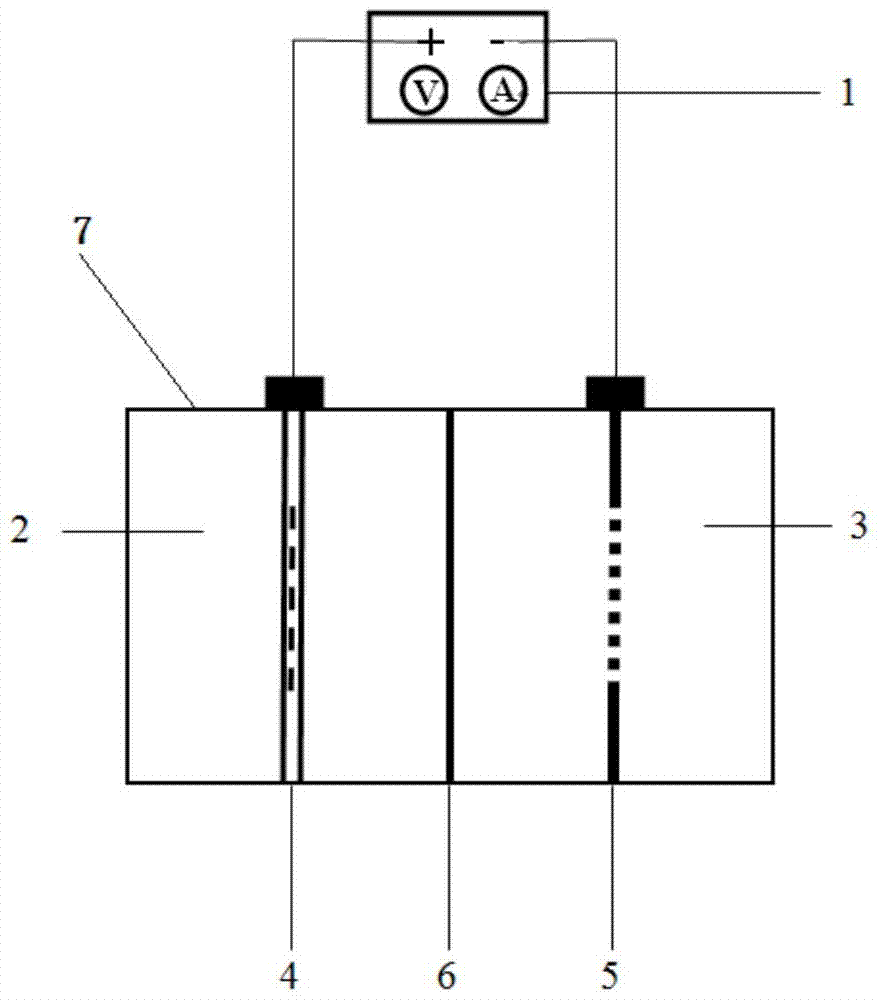

[0024] see figure 1 According to the present invention, the device for combined electrochemical cathode and anode treatment of wastewater mainly includes: an electrolytic cell 7 , a diaphragm 6 , an anode 4 and a cathode 5 . The diaphragm 6 is arranged in the middle of the electrolytic cell 7, and the electrolytic cell 7 is divided into an anode chamber 2 and a cathode chamber 3, which are independent of each other. The anode 4 is arranged in the anode chamber 2, and the cathode 5 is arranged in the cathode chamber 3, wherein the anode chamber 2 and the cathode cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com