Denitrogenation agent

A technology of denitrification agent and auxiliary components, which is applied in the direction of water pollutants, water/sludge/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problems of complex operation, difficult treatment, and low stability of biochemical systems. Achieve the effect of simple processing and preparation, high removal efficiency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

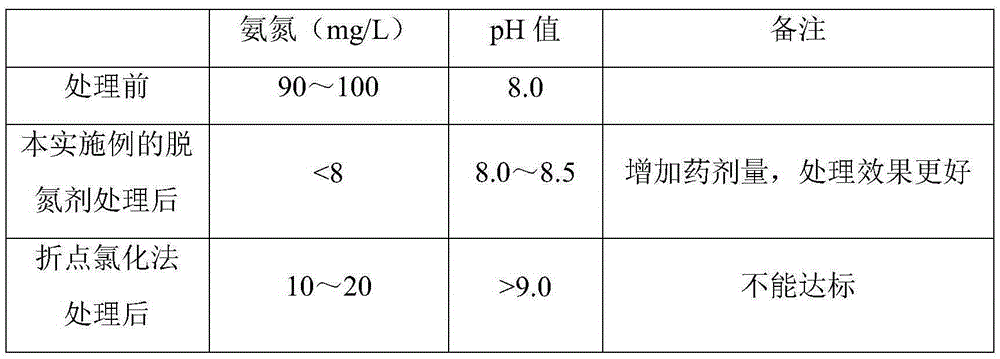

[0023] Example: The denitrification agent of the present invention is applied to a sewage treatment station of a smelting wastewater plant. The influent of the wastewater station is smelting wastewater, in which the concentrations of heavy metals and ammonia nitrogen are high. The process adopts the stripping method to remove a large amount of ammonia nitrogen. Precipitation method + filtration to remove heavy metals, the heavy metals in the treated effluent meet the standard, but the ammonia nitrogen content far exceeds the discharge standard, the agent of the present invention is added to the intermediate pool after the sedimentation tank and before the filter tank to remove residual ammonia nitrogen.

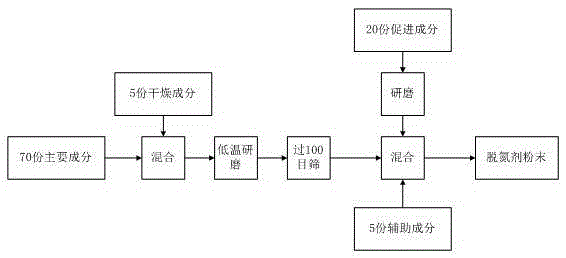

[0024] The denitrification agent formula provided in this embodiment is: the proportion of main components (sodium chlorite: potassium hypochlorite: sodium trichloroisocyanurate = 1:2:3) is 70% (mass percentage, the same below) , promoting components (MnO 2 : FeCl 3 =1︰5) ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com