Self-cleaning micro-aeration compound constructed wetland sewage treatment system

A technology of sewage treatment system and constructed wetland, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Easy to block and other problems, to achieve the effect of strengthening aerobic-anoxic environment, saving energy consumption and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

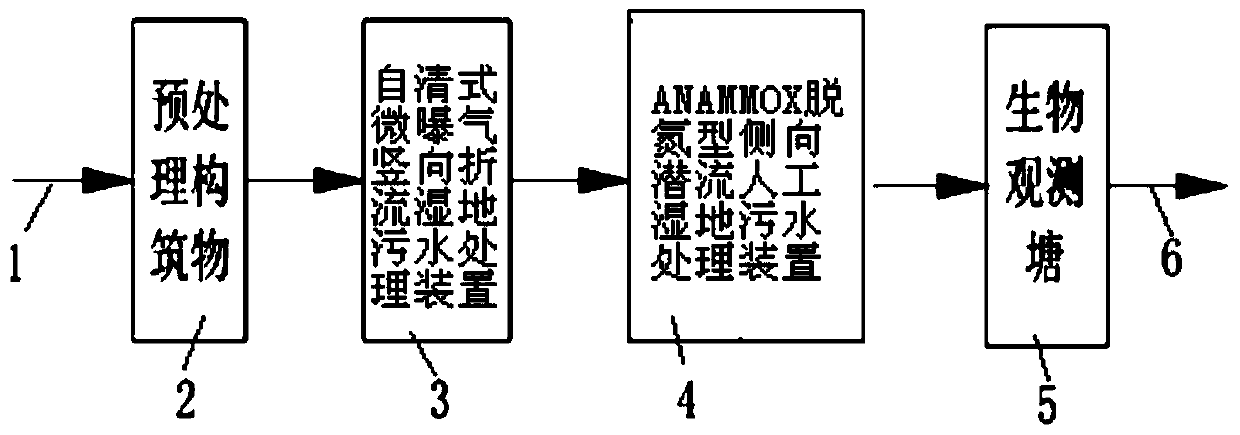

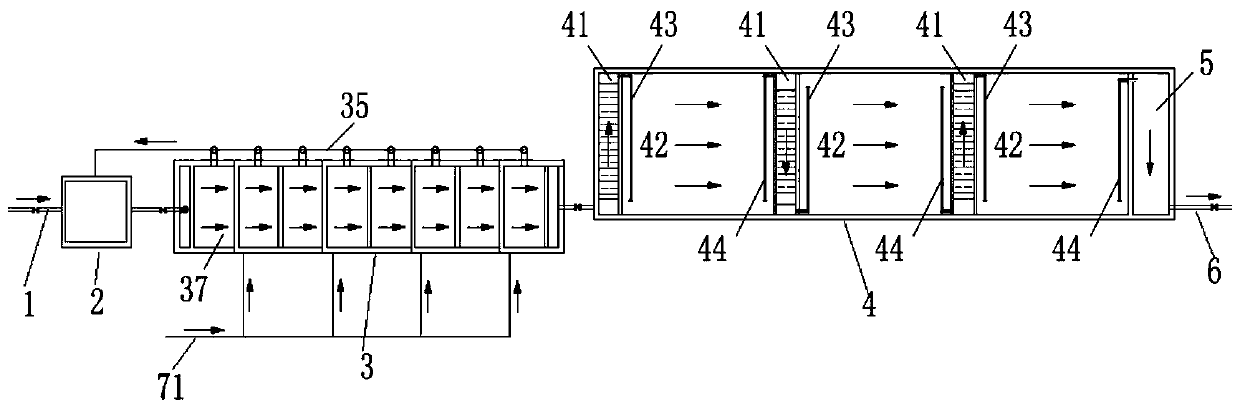

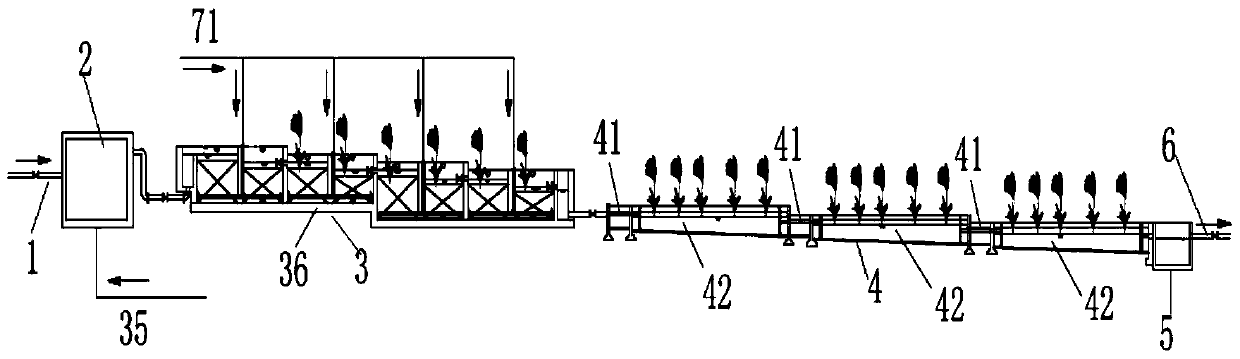

[0048] Embodiment 1 The structure of the sewage treatment system of the present invention is shown in Figure 2 and Figure 3. The self-cleaning micro-aeration composite constructed wetland sewage treatment system includes pretreatment structures 2 connected in sequence by pipelines, self-cleaning micro-aeration vertical folding Flow wetland sewage treatment device 3, lateral subsurface flow constructed wetland sewage treatment device that can realize ANAMMOX denitrification 4, biological observation pond 5.

[0049] The pretreatment structure 2 can be a sedimentation pond or biogas pond, or a natural pond.

[0050] As shown in Figure 4, the self-cleaning micro-aeration vertical baffle wetland sewage treatment device 3 consists of a water distribution area 31, a pool body 36, an aeration pipe, a backwash pipe, a water collection area 34, a packing layer 39 and aquatic plants 38 . Along the flow direction are anaerobic wetlands, carbon oxidation wetlands and short-range nitrific...

Embodiment 2

[0054] Example 2 Sewage treatment using the treatment system of the present invention

[0055] 1. When the system works normally, the implementation method is as follows, and the flow chart is shown in Figure 1:

[0056] Urban sewage enters the pretreatment structure through the system inlet pipe to remove floating solids, suspended solids, sediment and some organic matter with large particle sizes.

[0057] Sewage enters the pretreatment structure from the system inlet pipe, and then is sequentially treated by the self-cleaning micro-aeration vertical deflection wetland sewage treatment device and the ANAMMOX denitrification type lateral subsurface flow constructed wetland sewage treatment device, and then enters the biological observation pond. The tank body of the self-cleaning micro-aeration vertical baffle wetland sewage treatment device is divided into three sections: anaerobic, aerobic and micro-aerobic sections along the direction of water flow. For wetlands and carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com