Recycling technology for sludge generated after sewage treatment

A sludge recycling and sewage treatment technology, applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc. Low mud disposal cost and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

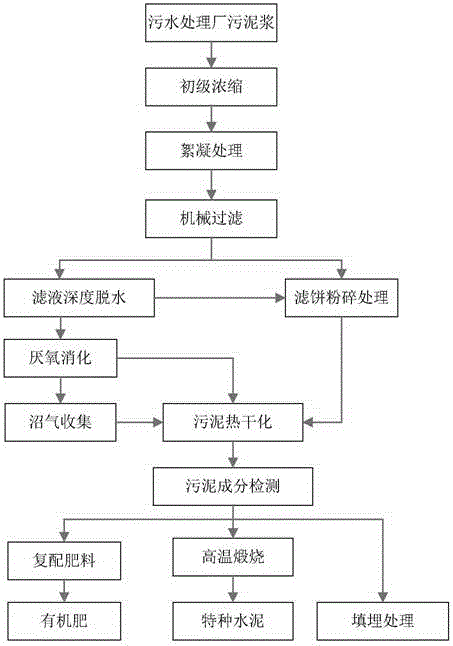

Image

Examples

Embodiment 1

[0020] A sludge recycling technology after sewage treatment, which specifically includes the following steps: Concentration: use centrifugal concentration to reduce the water content of the sludge from 99.2% to 99.5% to 94%, add diatomaceous earth, microbial flocculant (MBF), The compound mass ratio of diatomite to MBF is 50:1, and then a certain proportion of quicklime is added to make a modified diatomite containing 35% calcium carbonate. After conditioning, mechanical dehydration is used to force the sludge water to pass through the filter medium , to form a filtrate, and then the solid particles are trapped on the medium to form a filter cake; add 25mg / gTS protease and 0.2g / gTS concentration of EDTA-2Na salt at 100°C to destroy the cell and colloidal structure of the sludge and reduce Combining the water capacity and compressibility of the sludge, deep dehydration is carried out to make the moisture content of the sludge below 30%; the sludge is subjected to thermal hydroly...

Embodiment 2

[0022] A sludge recycling technology after sewage treatment, which specifically includes the following steps: Concentration: use centrifugal concentration to reduce the water content of the sludge from 99.2% to 99.5% to 94%, add diatomaceous earth, microbial flocculant (MBF), The compounding mass ratio of diatomite to MBF is 30:1, and then a certain proportion of quicklime is added to make a modified diatomite containing 25% calcium carbonate. After conditioning, mechanical dehydration is used to force the sludge water to pass through the filter medium , to form a filtrate, and then the solid particles are trapped on the medium to form a filter cake; add 25mg / gTS protease and 0.2g / gTS concentration of EDTA-2Na salt at 110 ° C to destroy the cell and colloidal structure of the sludge and reduce Combining the water capacity and compressibility of the sludge, deep dehydration is carried out to make the moisture content of the sludge below 30%; the sludge is subjected to thermal hy...

Embodiment 3

[0024] A sludge recycling technology after sewage treatment, which specifically includes the following steps: Concentration: use centrifugal concentration to reduce the water content of the sludge from 99.2% to 99.5% to 94%, add diatomaceous earth, microbial flocculant (MBF), The compound mass ratio of diatomite to MBF is 5:1, and then put in a certain proportion of quicklime to prepare a modified diatomite containing 25% calcium carbonate. After conditioning, use mechanical dehydration to force the sludge water to pass through the filter medium , to form a filtrate, and then the solid particles are trapped on the medium to form a filter cake; add 25mg / gTS protease and 0.2g / gTS concentration of EDTA-2Na salt at 120°C to destroy the cell and colloidal structure of the sludge and reduce Combining the water capacity and compressibility of the sludge, deep dehydration is carried out to make the moisture content of the sludge below 20%; the sludge is subjected to thermal hydrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com