Preparing method for ion exchange resin, negative ion chromatographic column prepared from ion exchange resin prepared through method and application of negative ion chromatographic column

A technology of ion exchange resin and deionized water, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve problems such as uneven quality and unsatisfactory demand, and achieve quality improvement and long service life , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

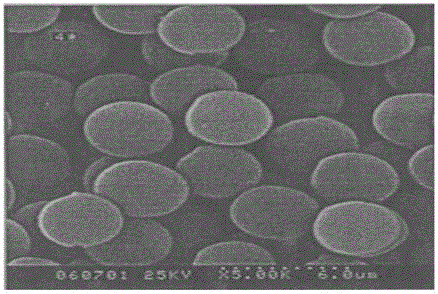

[0032] A kind of preparation method of ion exchange resin for anion chromatographic column, concrete steps are as follows:

[0033] (1) a. Mix polyvinyl alcohol with a degree of polymerization of 400---1200 and deionized water, the dosage ratio of the two is 30:100, then stir at a speed of 5000 rpm, and simultaneously heat up to 60°C; After complete dissolution, add 5 drops of methylene blue aqueous solution;

[0034] b. Mix dibenzoyl peroxide, styrene and divinylbenzene, stir gently, and add dropwise to the aqueous solution of the dispersant after the dibenzoyl peroxide is completely dissolved;

[0035] The styrene is selected from HPLC grade. Before use, it is washed 10 times with a 10% NaOH solution, then washed with water until neutral, then dried with a silica desiccant for 36 hours, and finally filtered with a vacuum pump. The control temperature is 70 degrees.

[0036] The divinylbenzene is of superior grade, and is dried with anhydrous magnesium sulfate for 36 hours ...

Embodiment 2

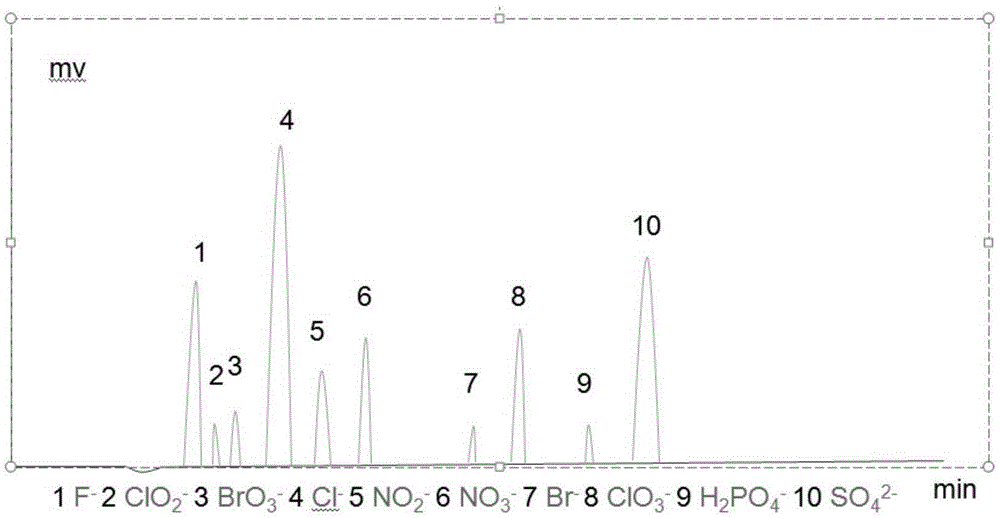

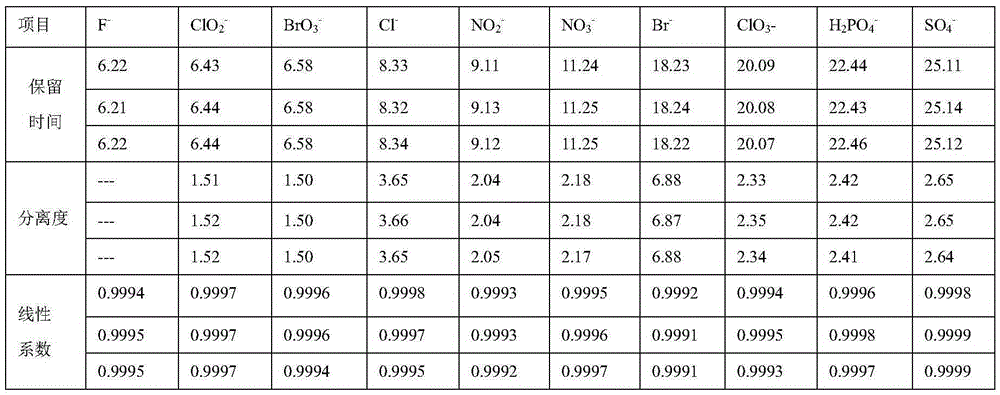

[0045] One can complete F at the same time - , ClO 2 - , BrO 3 - , Cl - , NO 2 - , NO 3 - 、Br - , ClO 3 - 、H 2 PO 4 - and SO 4 2- The chromatographic columns of ten kinds of anions, etc., have used the ion-exchange resin prepared by embodiment 1, and the packing steps are:

[0046] (1) Connect the air compressor and chromatographic column packing machine required for column packing to ensure that the body of the column packing machine is stable when it is working;

[0047] (2) Weigh 3.2g of ion exchange resin; dissolve the filler with 50ml of isopropanol, stir it evenly with a glass rod, and use ultrasonic wave for 3 minutes;

[0048] (3) Quickly pour the above mixed solution into the homogenization tank. If the homogenization tank is not full, fill it up with isopropanol, and quickly connect the homogenization tank and the column to the pump with a pressure of 60MPA to methanol (chemically pure) Make the mobile phase, turn on the column packing machine, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com