Composite additive for preventing diesel anti-wear agent from generating spontaneous combustion

A technology of compound additives and anti-wear agent, applied in the field of unsaturated fatty acid or ester self-ignition flame retardant, can solve the problems of self-ignition, harmful to the engine or the environment, unworkable, etc., and achieves low material cost, increased heating starting temperature, and high heat generation. Effect of starting temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

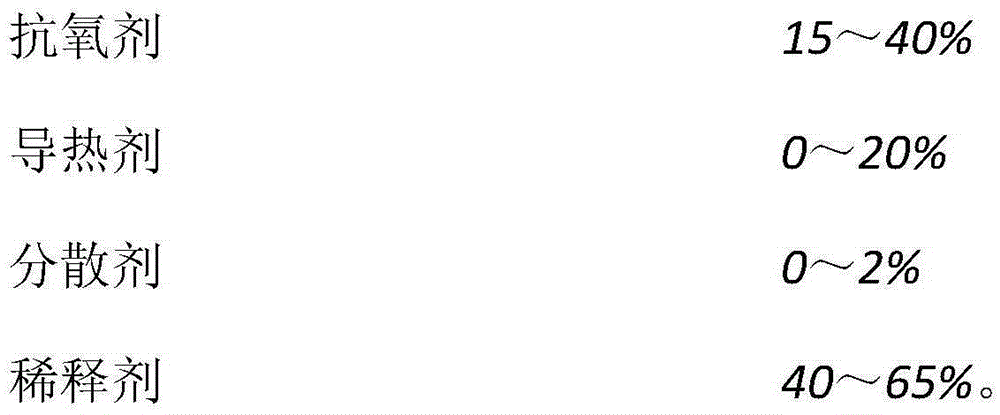

Method used

Image

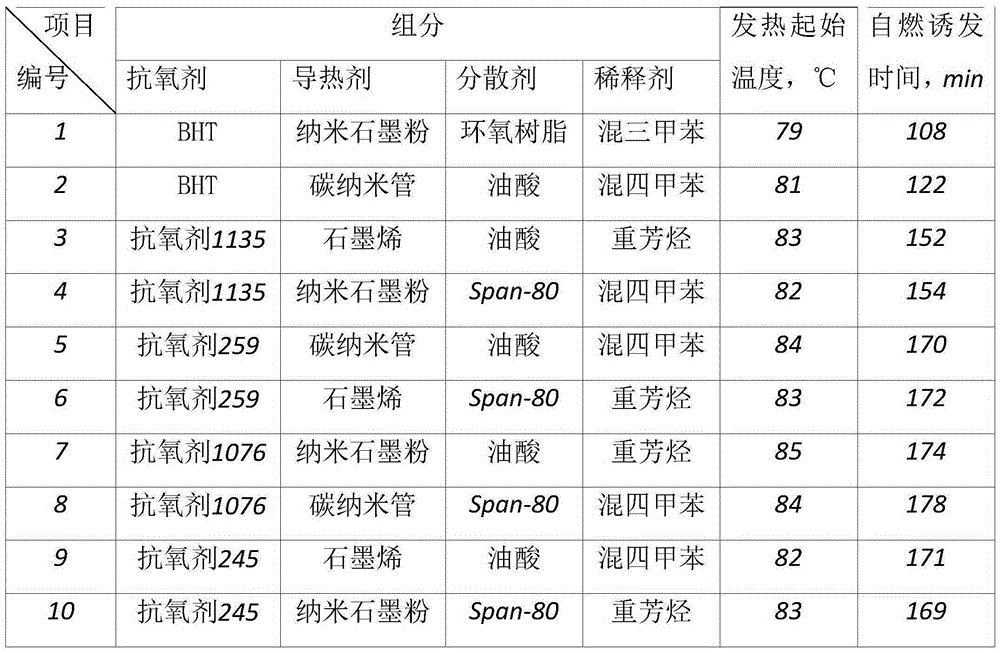

Examples

Embodiment 1

[0020] Sample Preparation:

[0021] Weigh the antioxidant, heat conducting agent, dispersant and diluent respectively, and mix thoroughly to obtain the composite inhibitor of the present invention. Select a commercially available acid-type or ester-type anti-wear agent, add the prepared composite inhibitor in proportion, and mix thoroughly, which is the sample of this embodiment.

[0022] Evaluation method:

[0023] 1) TG‐TDA (Thermogravimetric Differential Thermal Analysis) is used to measure the onset temperature of heat generation during heating. The higher the temperature, the higher the rate of spontaneous combustion resistance. Test conditions: ①sample amount: 10mg; ②heating rate: 2°C / min; ③air flow: 150mL / min.

[0024] 2) SIT (Spontaneous Ignition Test) is used to measure the time from heat generation to spontaneous combustion. The longer the time, the higher the rate of spontaneous combustion resistance. Test conditions: ①sample amount: 30mg; ②temperature: 60℃; ③env...

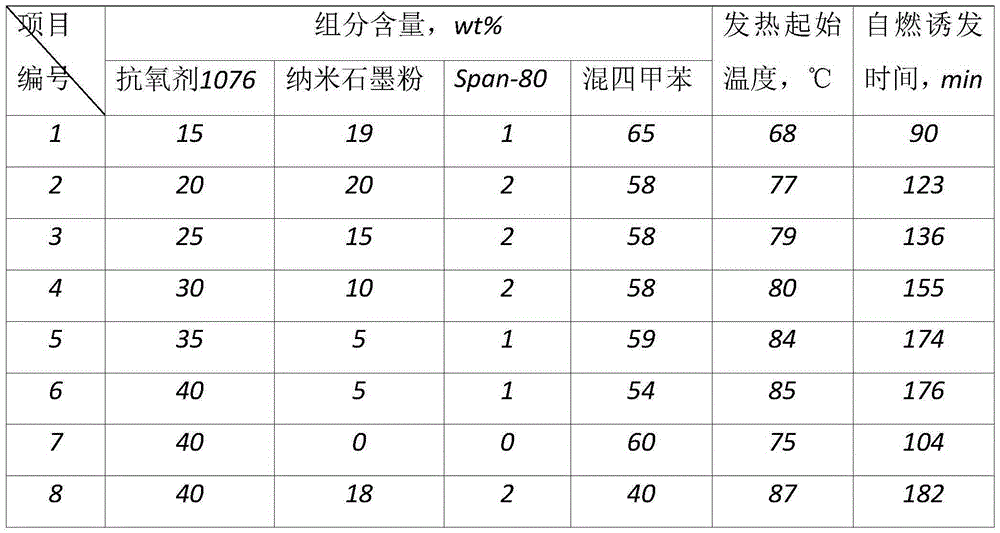

Embodiment 2

[0030] Sample preparation and evaluation methods are the same as in Example 1.

[0031] Table 2 Effects of different component contents on the effect of spontaneous combustion retardation

[0032]

[0033] Note: 1) Dosage increased by 1%; 2) The anti-wear agent used in the test was a commercially available acid-type anti-wear agent (containing 80-90% tall oil fatty acid)

[0034] According to the data in the table, combined with cost considerations, the optimal component mass ratio of the spontaneous combustion retardant is antioxidant 1076: nano-graphite powder: Span-80: mixed tetramethylbenzene = 35:5:1:59.

Embodiment 3

[0036] Sample preparation and evaluation methods are the same as in Example 1.

[0037] Table 3 The influence of different test objects and doses on the effect of spontaneous combustion retardation

[0038]

[0039]

[0040] Note: Inhibitor components and content are

[0041]

[0042] From the data in the table, it can be seen that the self-flammability retardant of the present invention is effective for both acid type and ester type antiwear agents. Considering comprehensively, the optimal addition amount is 1‐2%. It has been verified that adding the anti-wear agent added with the self-ignition retardant of the present invention to diesel oil has no adverse effect on the physical and chemical indicators of the diesel oil, such as the anti-wear property, cetane number, and actual colloid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com