A kind of preparation method of anti-oxidation lubricating oil for internal combustion engine

A lubricating oil and internal combustion engine technology, applied in the field of lubricating oil, can solve the problems of lubricating oil being easily oxidized, and achieve the effects of excellent shear stability, avoiding acid corrosion, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

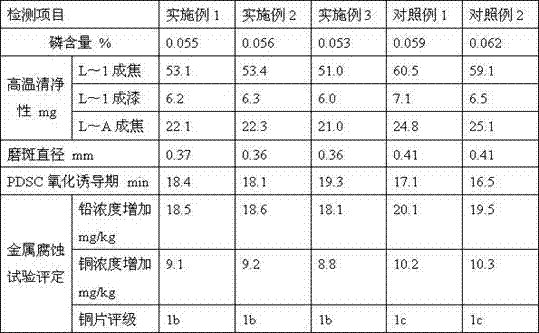

Examples

Embodiment 1

[0025] Step 1, 100Kg of the second-class hydrogenated base oil 500N, high alkali value calcium sulfonate (calcium octadecylbenzenesulfonate with a base value of 320KOH / g) 4Kg, hydroxyethylidene diphosphonic acid 3Kg, sulfur phosphorus Butyl octanol zinc salt 2Kg, di-secondary alcohol alkyl zinc dithiophosphate 1Kg, mixed and heated to 50°C to obtain the first mixture;

[0026] Step 2: In the first mixture, add 1Kg of monosuccinimide, 1Kg of polymethacrylate, 1Kg of triethyl phosphate, and 1Kg of fumarate, heat up to 60°C and stir to obtain the second mixture ;

[0027] Step 3. In the second mixture, add alkenyl succinic acid 2Kg, benzotriazole 2Kg, 2,6-tert-butyl p-cresol 1Kg, dimethyl tin 1Kg, silicone oil 3Kg, polyvinyl alcohol 4Kg, heated up to 50°C and then stirred to obtain lubricating oil.

Embodiment 2

[0029] Step 1, 150Kg of the second-class hydrogenated base oil 500N, high alkali value calcium sulfonate (calcium octadecylbenzenesulfonate with a base value of 320KOH / g) 7Kg, hydroxyethylidene diphosphonic acid 6Kg, sulfur phosphorus 3Kg of butyl octanol zinc salt, 2Kg of di-secondary alcohol alkyl dithiophosphate zinc, mixed and heated to 60°C to obtain the first mixture;

[0030] Step 2: In the first mixture, add 3Kg of monosuccinimide, 3Kg of polymethacrylate, 2Kg of triethyl phosphate, and 3Kg of fumarate, heat up to 70°C and stir to obtain the second mixture ;

[0031] Step 3. In the second mixture, add alkenyl succinic acid 5Kg, benzotriazole 3Kg, 2,6-tert-butyl p-cresol 2Kg, dimethyl tin 3Kg, silicone oil 5Kg, polyvinyl alcohol 6Kg, heated up to 60°C and then stirred to obtain lubricating oil.

Embodiment 3

[0033] Step 1, the second type of hydrogenated base oil 500N 120Kg, high alkali value calcium sulfonate (calcium octadecylbenzenesulfonate with a base value of 320KOH / g) 6Kg, hydroxyethylidene diphosphonic acid 5Kg, sulfur phosphorus 2Kg of butyl octanol zinc salt, 1Kg of di-secondary alcohol alkyl zinc dithiophosphate, mixed and heated to 55°C to obtain the first mixture;

[0034] Step 2: In the first mixture, add 2Kg of monosuccinimide, 2Kg of polymethacrylate, 2Kg of triethyl phosphate, and 2Kg of fumarate, heat up to 65°C and stir to obtain the second mixture ;

[0035] Step 3: In the second mixture, add alkenyl succinic acid 4Kg, benzotriazole 3Kg, 2,6-tert-butyl p-cresol 2Kg, dimethyl tin 2Kg, silicone oil 4Kg, polyvinyl alcohol 5Kg, heated up to 55°C and then stirred to obtain lubricating oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com