Preparation method of magnetic hydroxyapatite immobilized lipase and application in edible fat and oil processing

A technology of immobilized lipase and hydroxyapatite, which is applied in the direction of immobilized on or in the inorganic carrier, edible oil/fat, application, etc., can solve the problems of use restrictions, increase the risk of cardiovascular and cerebrovascular diseases, etc., and achieve increased The effect of loading capacity, increasing contact mass transfer rate and uniformity, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

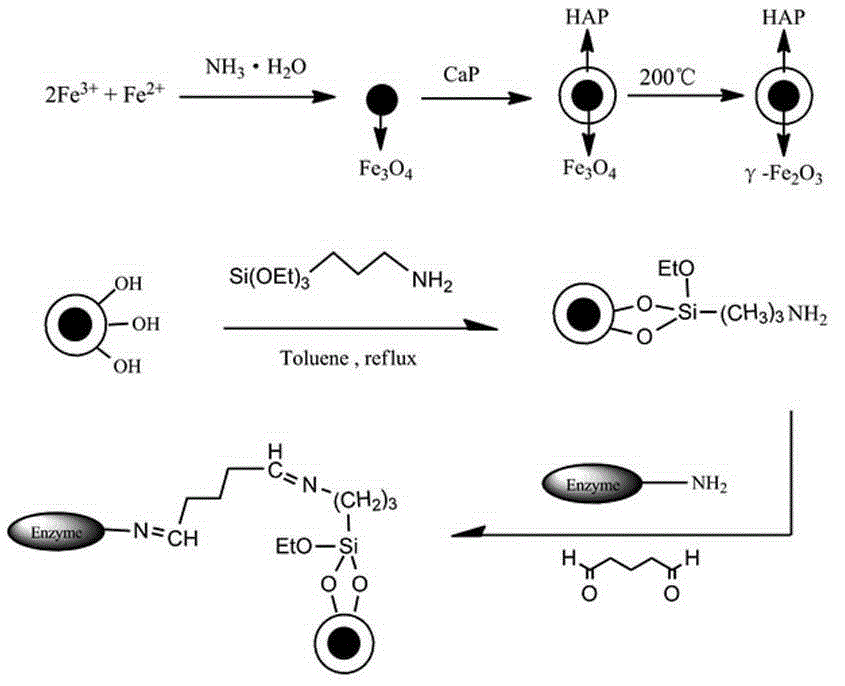

[0036] The preparation method of magnetic hydroxyapatite immobilized lipase of the present invention is as follows figure 1 shown, including the following steps:

[0037] The first step, the preparation of magnetic hydroxyapatite

[0038] A certain amount of FeCl 3 ·6H 2 O and Fe 2 SO 4 ·7H 2 O was put into a beaker, deoxygenated water was added, and mechanically stirred to make FeCl 3 ·6H 2 O and Fe 2 SO 4 ·7H 2 O is completely dissolved; then slowly add 25% NH 3 ·H 2 O solution in the mixed solution, stirred at 25°C for 30min; then slowly added Ca(NO 3 ) 2 4H 2 0 solution and (NH 4 ) 2 HPO 4 The solution is in the above reaction system, continue to stir for 30 minutes and then heat up to 90°C. After it has fully reacted, cool the product to room temperature and age overnight. The product is magnetically separated and washed with deionized water until it is neutral, and dried at 200°C. Calcined under the conditions for 3h to obtain magnetic hydroxyapatite ca...

Embodiment 1

[0051] (1) HAP-γ-Fe 2 o 3 Preparation of vector

[0052] Weigh 3.0gFeCl 3 ·6H 2 O and 1.54gFe 2 SO 4 ·7H 2 O in a 500mL beaker, add 90mL deoxygenated water, stir mechanically to make FeCl 3 ·6H 2 O and Fe 2 SO 4 ·7H 2 O is completely dissolved, then slowly add 30mL of 25% NH 3 ·H 2 O in the mixed solution, kept stirring at 25°C for 30 minutes, and 7.1g Ca(NO 3 ) 2 4H 2 O and 2.3g (NH 4 ) 2 HPO 4 Dissolve in 67mL of distilled water respectively, then slowly add these two solutions into the reaction system, continue stirring for 30min, then raise the temperature to 90°C, and react for 2h. After the reaction, the product was cooled to room temperature, aged overnight, the product was magnetically separated and washed with deionized water to neutrality, dried and calcined at 200°C for 3 hours to obtain HAP-γ-Fe 2 o 3 carrier.

[0053] (2) Amino functional modification of the carrier

[0054] Weigh 1.0gHAP-γ-Fe 2 o 3 The carrier was placed in a dry 100mL rou...

Embodiment 2

[0058] HAP-γ-Fe 2 o 3 The preparation and the amino functional modification method of the carrier are the same as in Example 1.

[0059] Immobilization of lipase: Lipase was also immobilized using glutaraldehyde as a cross-linking agent. Take 0.5g amino-modified HAP-γ-Fe 2 o 3 In a 100mL dry round bottom flask, add 10mL of 10% glutaraldehyde solution, shake in a constant temperature oscillator for 0.5h at 35°C, then add 10mL of lipase solution (0.2mol / L phosphoric acid at pH 7.0 AY lipase was added to the buffer solution at a ratio of 0.075g / mL and then mixed), and the shaking reaction was continued for 8h. After the reaction, the immobilized lipase was magnetically separated, washed with 0.2 mol / L phosphate buffer solution (pH=7.0), and freeze-dried to obtain the finished product of magnetically immobilized lipase—Catalyst 2#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com