Non-degenerated jellyfish collagen preparation method

A collagen, non-denaturing technology, applied in the field of preparing non-denaturing collagen, can solve the problems of high cost, unfavorable industrial promotion, low collagen yield and the like, and achieve the effects of complete structure, high purity and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The pretreatment of embodiment 1 pickled jellyfish processing leftovers

[0032] (1) Desalination: Rinse the marinated jellyfish processing scraps with clean water several times, then soak them in distilled water, and replace the distilled water every 2 hours for 1~2 days;

[0033] (2) Homogenization: Keep a certain proportion of water, grind it with a mixer until there are no obvious large particles, and then filter and drain with four layers of gauze;

[0034] (3) Degreasing: add acetone to a ratio of material to liquid of 1:5~1:20, let stand overnight, wash with a large amount of distilled water until there is no peculiar smell, then filter and drain with four layers of gauze;

[0035] (4) Impurity protein removal: Soak in 0.01-0.1mol / L disodium hydrogen phosphate solution of 5-20 times volume for 2-3 days, replace the solution every 6 hours, wash with a large amount of distilled water until neutral, and then use four Filter and drain with a layer of gauze, and st...

Embodiment 2

[0036] The optimization of embodiment 2 jellyfish collagen extraction process

[0037] (1) Determination of collagen extraction rate: adopt the determination method of hydroxyproline in the national standard GB / T9695.23-2008, indirectly quantify collagen through the content of hydroxyproline, and convert collagen into hydroxyproline The coefficient is 11.1. With the concentration of standard L-hydroxyproline (μg / mL) as the abscissa and the absorbance value A560 as the ordinate, draw the standard curve, and get the linear regression equation A560=0.2193C+0.011, R=0.9993;

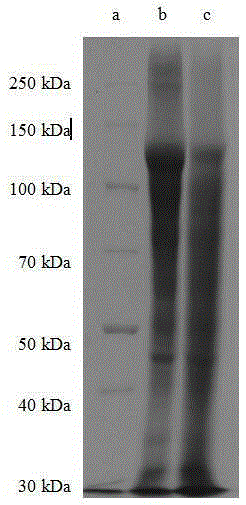

[0038] (2) Determination of the integrity of the collagen triple helix structure: SDS-PAGE was used to analyze whether the collagen triple helix structure was destroyed. The separating gel concentration is 7.5%, and the stacking gel concentration is 3.5%;

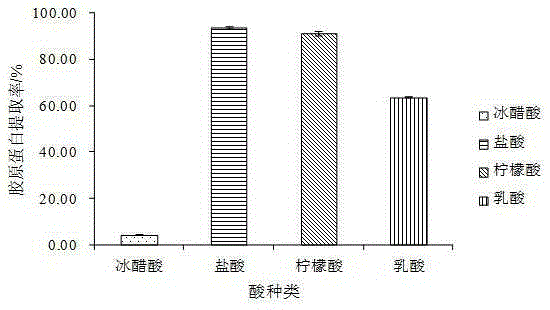

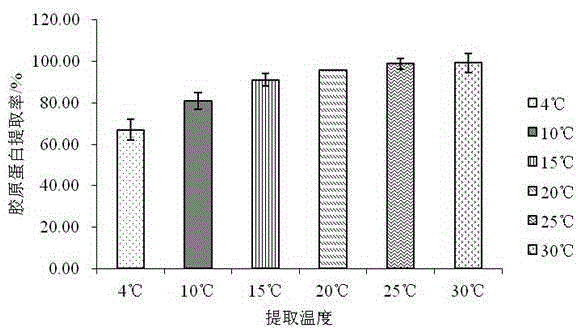

[0039] (3) Determination of the best type of acid: different extractants (glacial acetic acid, hydrochloric acid, citric acid and lactic acid) on col...

Embodiment 3

[0048] The separation and purification of embodiment 3 jellyfish collagen

[0049] (1) Slowly add high-concentration NaCl solution to the crude jellyfish collagen extract to a final concentration of 1.0mol / L, and stir overnight;

[0050] (2) Centrifuge the crude extract at 20,000g for 15min at 4°C, take the precipitate and redissolve it in 1mmol / L citric acid, transfer it to a 40kDa dialysis bag, place it in distilled water for dialysis for 3 days, and replace the distilled water every 6 hours during this period;

[0051] (3) The dialysate was centrifuged at 20,000g for 15min at 4°C, and the precipitate was freeze-dried to obtain dry collagen cotton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com