Method for purifying bisphenol compound in surface water sample extraction liquid

A technology of surface water and extraction liquid, which is applied in the preparation of test samples, etc., can solve the problems of bisphenol compounds affecting the water body matrix, and achieve the effects of reducing inhibition effect, shortening time, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

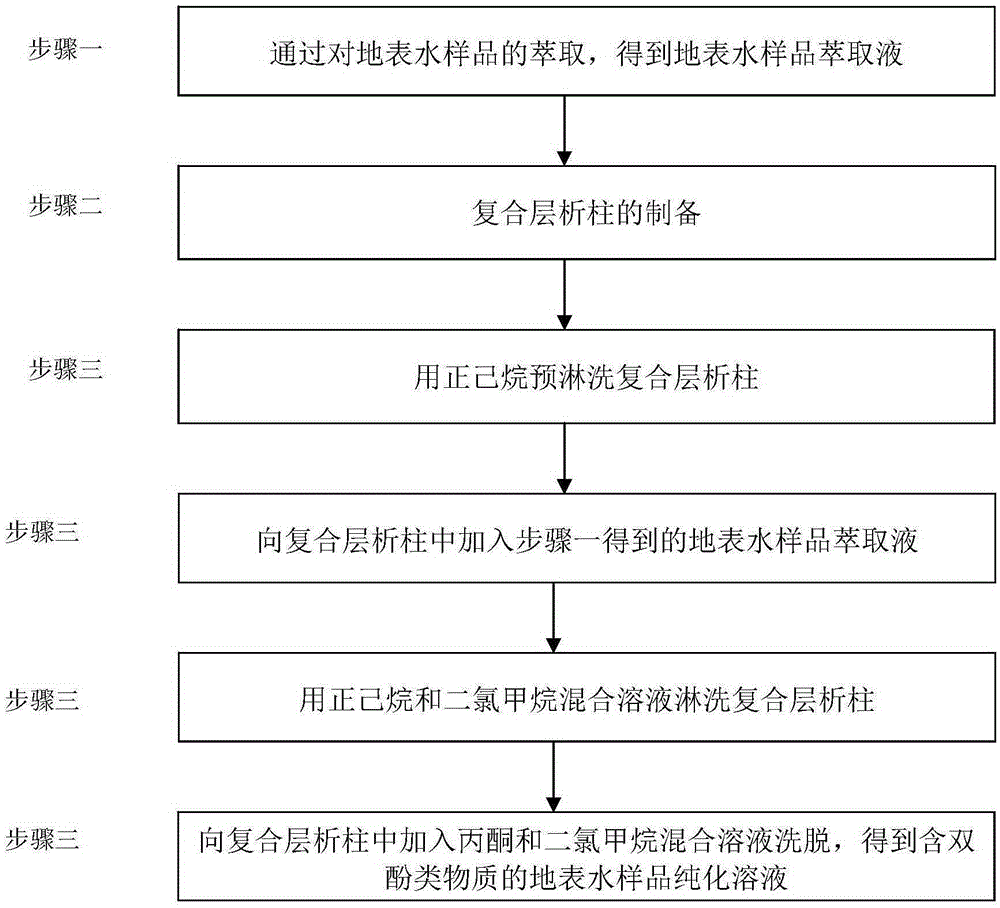

[0020] Specific implementation mode one: as figure 1 As shown, a method for purifying bisphenols in the surface water sample extract comprises the following steps:

[0021] Step 1: Obtain the surface water sample extract by extracting the surface water sample;

[0022] Step 2: preparation of composite chromatographic column;

[0023] Take an all-glass chromatography column with a PTFE joint door at the bottom, and fill in the glass wool layer, the first anhydrous sodium sulfate layer, the florisil layer, the neutral silica layer, the acid silica layer and the The second anhydrous sodium sulfate layer;

[0024] Using the sulfonation of sulfuric acid, the acidic silica gel is placed on the upper layer to remove most of the matrix effect first, which is helpful for the purification of the lower column chromatography. The lower layer of Florisil can better separate bisphenols and water. Humic acid and pigments in environmental samples;

[0025] Step 3: pre-washing the composit...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the specific process of the extraction of the surface water sample in the step one is:

[0030] (1) Take a surface water sample, adjust pH=4, take a WatersOasisHLB solid phase extraction column, use an automatic solid phase extraction instrument, activate the solid phase extraction column with ethyl acetate, methanol, and pure water in sequence, and use WatersOasisHLB as the solid phase extraction column model;

[0031] (2) Take the water sample after adjusting the pH value and pass through the solid phase extraction column at a flow rate of 2-5mL / min;

[0032] (3) After loading the sample, use ultrapure water as the eluent to rinse the solid-phase extraction column to remove impurities;

[0033] (4) After the solid-phase extraction column is dried under high-purity nitrogen, it is eluted twice with ethyl acetate. The mixed solution was redissolved and purified.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in the step 2, the all-glass chromatography column with a PTFE joint at the bottom has a column length of 45 cm and an inner diameter of 3 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Column length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com