Graphene-based enzyme-modified anode of biological fuel cell and preparation and application

A biofuel cell and graphene technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve problems such as high cost, narrow range of applicable substrates, and complicated preparation methods, and achieve low cost , easy preparation, good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

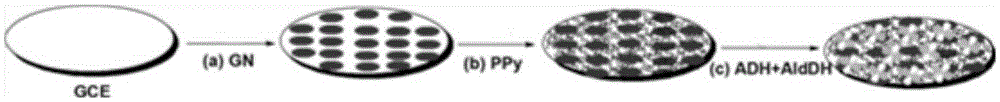

Method used

Image

Examples

Embodiment 1

[0040] (1) The glassy carbon electrode with a diameter of 3mm is used successively with Al with a diameter of 0.3μm and 0.05μm 2 O 3 The powder is polished to a mirror surface, rinsed with distilled water, then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, and then the glassy carbon electrode is placed in 0.5mol / L H 2 SO 4 Activate the electrode in the solution, take it out, rinse with distilled water, and dry to obtain the pretreated glassy carbon electrode;

[0041] (2) Weigh 100 mg of graphene and place it in a beaker, add 50 mL of distilled water, and ultrasound for 24 hours to obtain a 2 mg / mL graphene solution. Place the pretreated glassy carbon electrode in the graphene solution and use cyclic voltammetry Carry out electrochemical polymerization, with a polymerization potential of 0.2~0.9v, scan 18 circles at a speed of 0.05v / s, polymerize a layer of graphene, take it out, rinse, and dry naturally to obtain a GN modified electrode;

[0042] (3) The...

Embodiment 2

[0048] (1) The glassy carbon electrode with a diameter of 3mm is used successively with Al with a diameter of 0.3μm and 0.05μm 2 O 3 The powder is polished into a mirror surface, rinsed with distilled water, then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, and then the glassy carbon electrode is placed in 0.5mol / L H 2 SO 4 Activate the electrode in the solution, take it out, rinse with distilled water, and dry to obtain the pretreated glassy carbon electrode;

[0049] (2) Weigh 100 mg of graphene and place it in a beaker, add 50 mL of distilled water, and ultrasound for 24 hours to obtain a 2 mg / mL graphene solution. Place the pretreated glassy carbon electrode in the graphene solution and use cyclic voltammetry Carry out electrochemical polymerization, with a polymerization potential of 0.2~0.9v, scan 18 circles at a speed of 0.05v / s, polymerize a layer of graphene, take it out, rinse it, and dry it naturally to obtain a GN modified electrode;

[0050]...

Embodiment 3

[0055] (1) The glassy carbon electrode with a diameter of 3mm is used successively with Al with a diameter of 0.3μm and 0.05μm 2 O 3 The powder is polished into a mirror surface, rinsed with distilled water, then ultrasonically cleaned in absolute ethanol and distilled water for 1 min, and then the glassy carbon electrode is placed in 0.5mol / L H 2 SO 4 Activate the electrode in the solution, take it out, rinse with distilled water, and dry to obtain the pretreated glassy carbon electrode;

[0056] (2) Weigh 100 mg of graphene and place it in a beaker, add 50 mL of distilled water, and ultrasound for 24 hours to obtain a 2 mg / mL graphene solution. Place the pretreated glassy carbon electrode in the graphene solution and use cyclic voltammetry Carry out electrochemical polymerization, with a polymerization potential of 0.2~0.9v, scan 18 circles at a speed of 0.05v / s, polymerize a layer of graphene, take it out, rinse it, and dry it naturally to obtain a GN modified electrode;

[0057]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com