Method for preparing high-concentration nano silver monomer dispersion liquid

A technology of nano-silver and dispersion liquid, which is applied in the field of nano-technology and fine chemical industry, can solve the problems of small nano-silver particle size and high surface energy, and achieve the effects of wide pH controllable range, high sterilization rate and wide sterilization range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

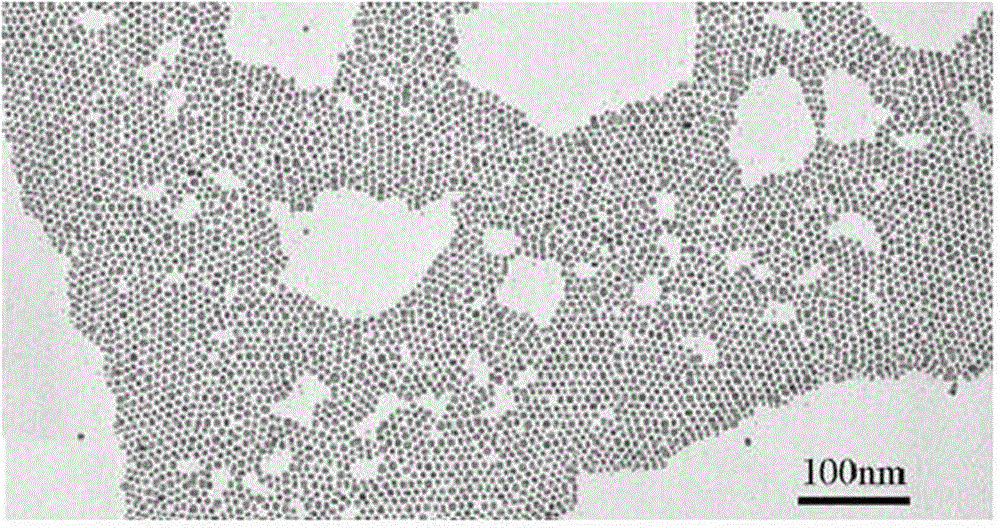

Image

Examples

Embodiment 1

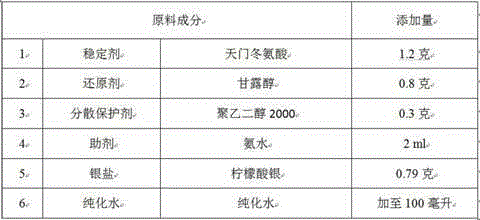

[0022] Take 100ml of the high-concentration dispersion liquid of nano-silver monomer to prepare a dispersion liquid with a nano-silver concentration of 5000ppm. The raw materials and proportioning ratio are shown in the following table:

[0023] Raw materials and ratio:

[0024]

[0025] Preparation:

[0026] (1) Add 1.2g of aspartic acid and 2ml of ammonia water additive into purified water, stir to dissolve;

[0027] (2) Add 0.79 grams of silver citrate, add water to 80ml, and set aside after dissolution;

[0028] (3) Add 0.8 g of mannitol and 0.3 g of polyethylene glycol 2000, stir and dissolve to form a uniform transparent solution, add purified water to 100 ml, and continue stirring for 2 hours to obtain a high-concentration nano-silver single substance dispersion of the target substance.

Embodiment 2

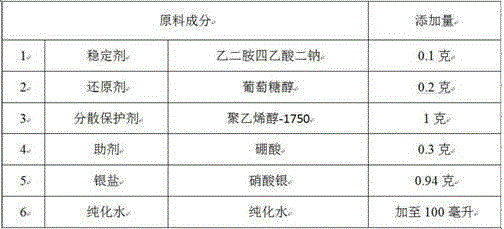

[0030] Take 100ml of the high-concentration dispersion of nano-silver monomer to prepare a dispersion with a nano-silver concentration of 6000ppm. The raw materials and proportioning ratio are shown in the following table:

[0031] Raw materials and ratio:

[0032]

[0033] Preparation:

[0034] (1) Add 0.1 g disodium edetate and 0.3 boric acid into purified water, stir to dissolve;

[0035] (2) Add 0.94 grams of silver nitrate, add water to 80ml, and set aside after dissolution;

[0036] (3) Add 0.2 g of glucitol and 1 g of polyvinyl alcohol-1750, stir to dissolve into a uniform transparent solution, add purified water to 100 ml, and continue stirring for 3 hours to obtain a high-concentration nano-silver single substance dispersion of the target;

[0037] In the nano-silver monomer dispersion prepared by the above method, the concentration of the monomer silver is 6000ppm, suspended in the solution in a monodisperse form; the particle size of the nano-silver is 5-10nm, ...

Embodiment 3

[0039] Take 100ml of the high-concentration dispersion of nano-silver monomer to prepare a dispersion with a nano-silver concentration of 6000ppm. The raw materials and proportioning ratio are shown in the following table:

[0040]

[0041] Preparation:

[0042] (1) Add 1.8 grams of water-soluble cyclodextrin and 2.5ml of lactic acid into purified water, stir to dissolve;

[0043] (2) Add 0.93 grams of silver citrate, add water to 80ml, and set aside after dissolution;

[0044] (3) Add 1.2 grams of xylitol and 0.6 grams of polyvinylpyrrolidone k-15, stir to dissolve into a uniform transparent solution, add purified water to 100ml, and continue stirring for 3 hours to obtain a high-concentration nano-silver single substance dispersion of the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com