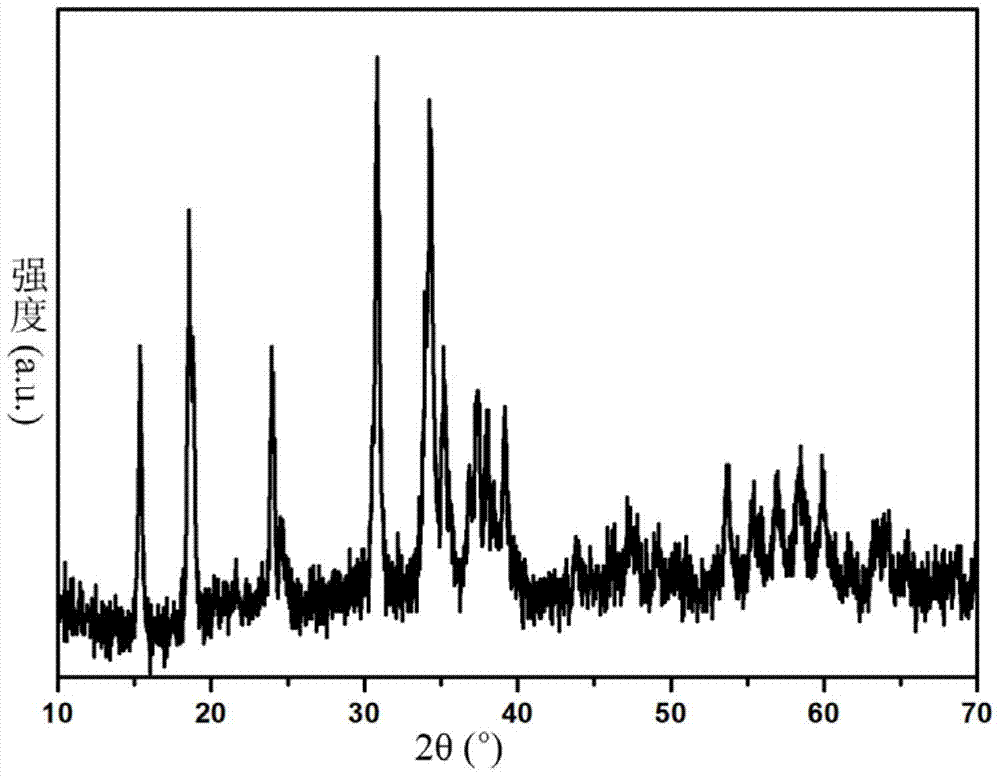

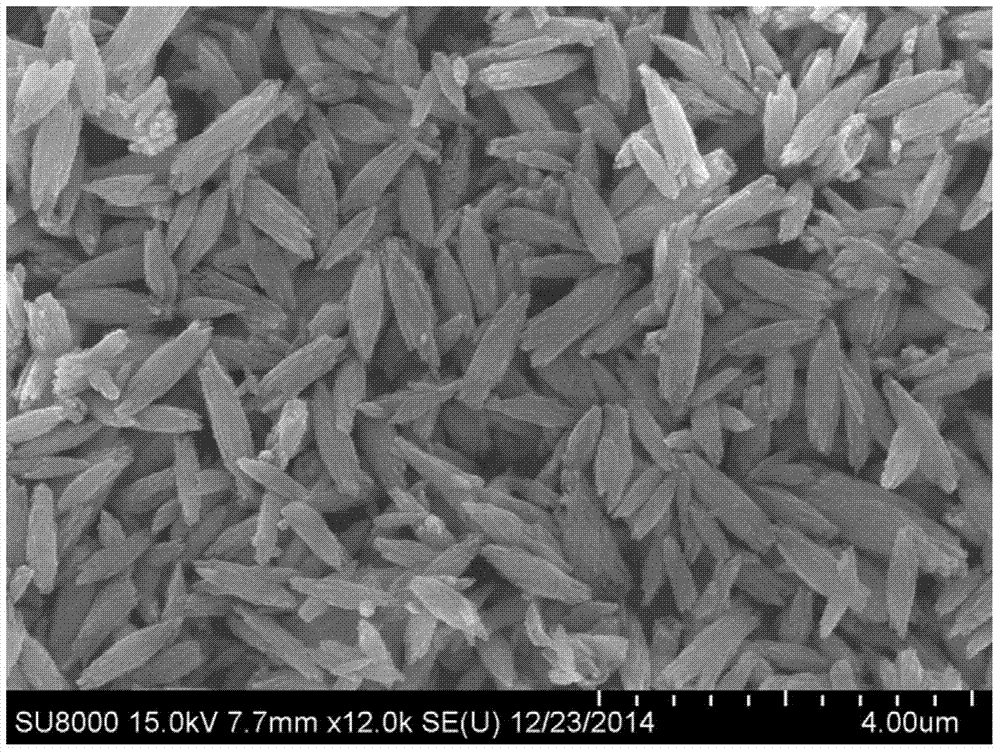

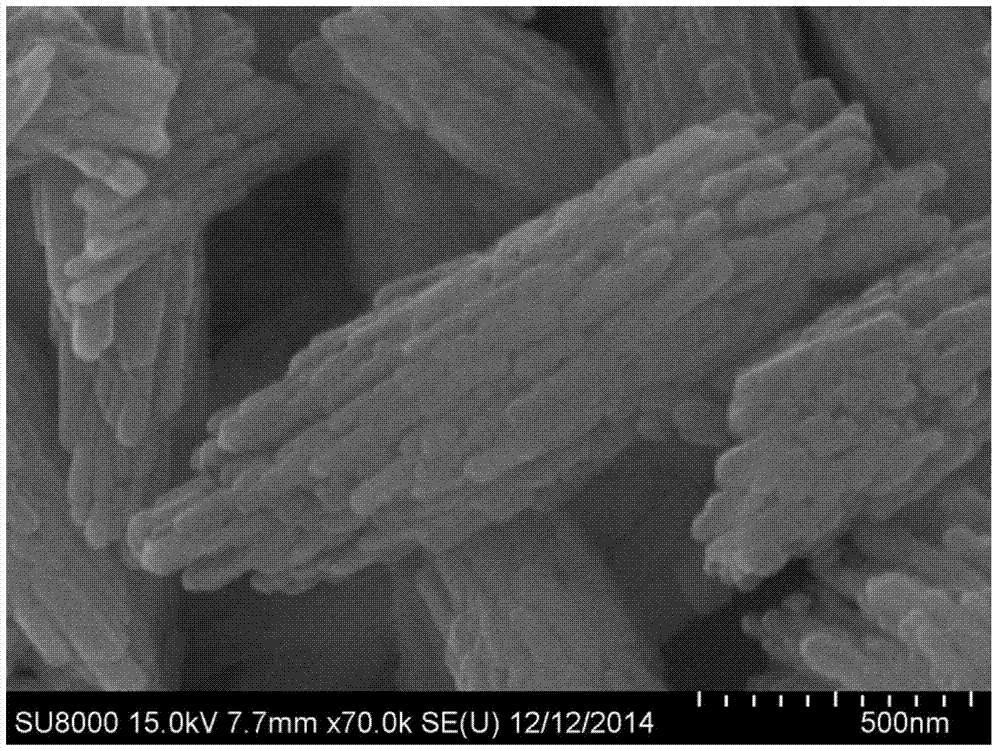

a hierarchical structure cu 2 (oh)po 4 Preparation methods of nanomaterials

A hierarchical structure, nanomaterial technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of easy production of copper by-products, unfavorable product separation, long synthesis cycle, etc., and achieve high product yield and crystallinity. Good, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Hierarchical structure Cu of the present invention 2 (OH)PO 4 Nanomaterials are prepared by simple and efficient "one pot" sonochemical technology, and the specific process steps are as follows:

[0025] (1) Weigh 0.2418g copper nitrate trihydrate Cu(NO 3 ) 2 ·3H 2 O is stirred and hydrolyzed into Sol A with 30mL deionized water;

[0026] (2) Weigh 0.0785g sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 O) be mixed with solution B with 26mL deionized water, the mol ratio of copper nitrate trihydrate and sodium dihydrogen phosphate is 2:1;

[0027] (3) Weigh 0.8g NaOH again, and use a 100mL volumetric flask to set the volume to the mark to make a NaOH solution C with a concentration of 0.2mol / L;

[0028] (4) While stirring, add solution B to solution A, and continue to stir for 10 minutes; then add solution C dropwise to the mixed reaction solution of A and B, and add 0.2mol / L NaOH solution C to 4.0mL . The total volume of the reaction solution was 60 mL.

[0029...

Embodiment 2

[0035] Hierarchical structure Cu of the present invention 2 (OH)PO 4 Nanomaterials are prepared by simple and efficient "one pot" sonochemical technology, and the specific process steps are as follows:

[0036] (1) Weigh 0.2415g copper nitrate trihydrate Cu(NO 3 ) 2 ·3H 2 O was stirred and hydrolyzed into sol A with 30mL deionized water;

[0037] (2) Weigh 0.0780g sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 O) be mixed with solution B with 24mL deionized water, the mol ratio of copper nitrate trihydrate and sodium dihydrogen phosphate is 2:1;

[0038] (3) While stirring, add solution B to solution A, and continue stirring for 10 minutes; then add dropwise 0.2 mol / L NaOH solution C prepared in Example 1 to make 6.0 mL. The total volume of the reaction solution was 60 mL.

[0039] (4) Transfer the reaction mixture to a 100mL blue cap bottle, place it in an ultrasonic cleaner filled with tap water, set the temperature of the ultrasonic bath to 90°C, and the ultrasonic i...

Embodiment 3

[0041] Hierarchical structure Cu of the present invention 2 (OH)PO 4 Nanomaterials are prepared by simple and efficient "one pot" sonochemical technology, and the specific process steps are as follows:

[0042] (1) Weigh 0.2414g copper nitrate trihydrate Cu(NO 3 ) 2 ·3H 2 O was stirred and hydrolyzed into sol A with 30mL deionized water;

[0043] (2) Weigh 0.0782g sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 O) be mixed with solution B with 26mL deionized water, the mol ratio of copper nitrate trihydrate and sodium dihydrogen phosphate is 2:1;

[0044] (3) Under stirring, add solution B to solution A, and continue to stir for 10 minutes; then add dropwise 0.2mol / L NaOH solution C prepared in Example 1 to be 4.0mL. The total volume of the reaction solution was 60 mL.

[0045] (4) Transfer the reaction mixture to a 100mL blue-capped bottle, place it in an ultrasonic cleaner filled with tap water, set the temperature of the ultrasonic bath to 60°C, and the ultrasonic irr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com