Method for treating yellow phosphorus production device phosphorus furnace gas condensate bled steam and recycling SiF4

A technology for condensing spent steam and producing equipment, applied in the field of phosphorus chemical industry, can solve problems such as not taking into account and not meeting environmental protection requirements, and achieve the effects of comprehensive utilization of environmental protection resources, low investment and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

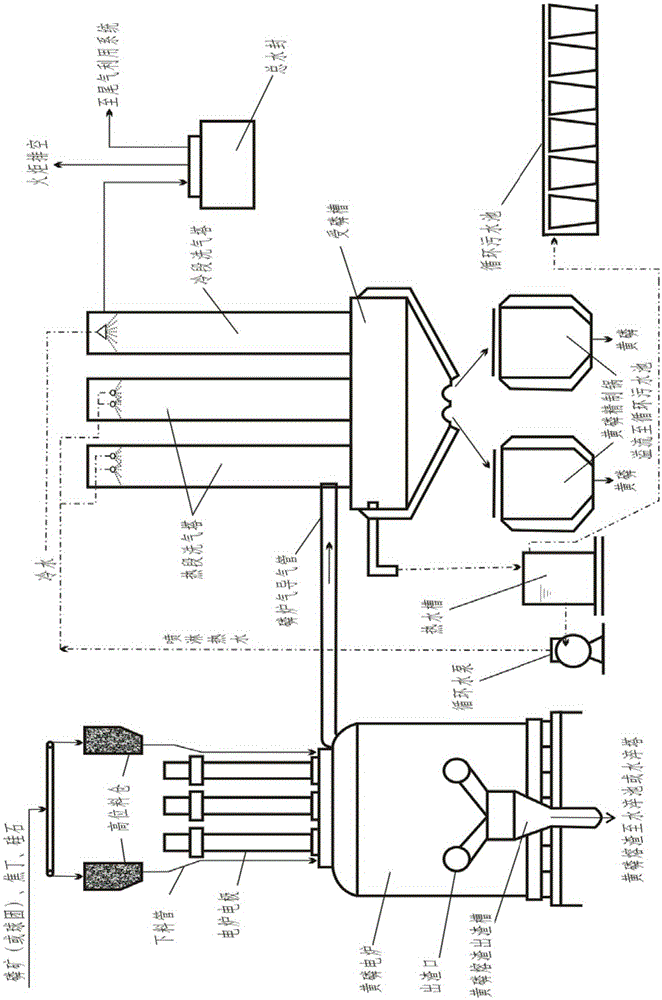

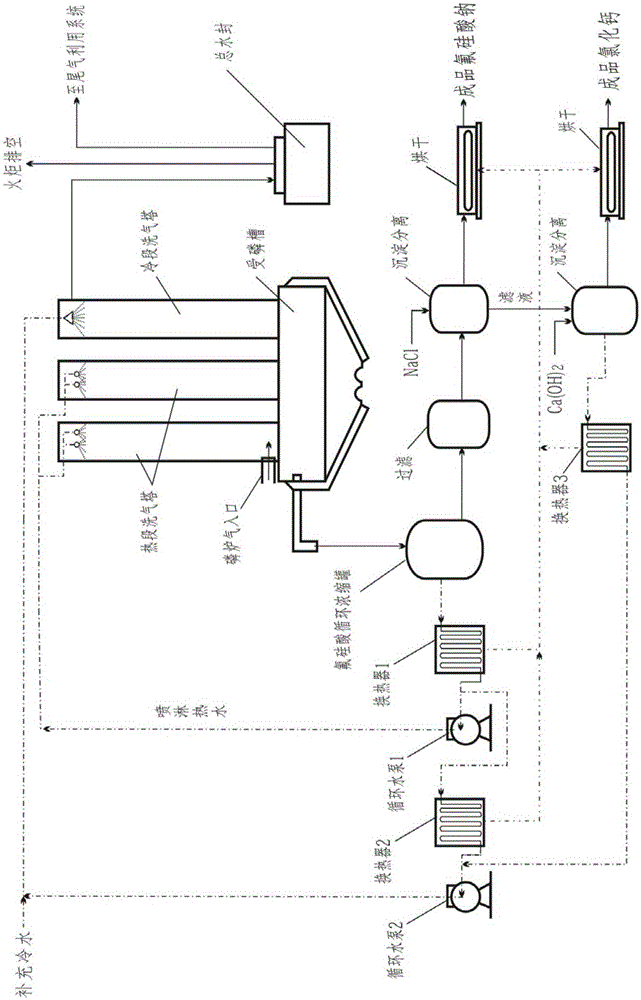

Image

Examples

Embodiment 1

[0054] The electric furnace capacity of a yellow phosphorus factory is 2×20000KVA, with P 2 o 5 content of 29%, SiO 2 Phosphate ore with a content of 13% and an F content of 1.5% is combined with coking coal and silica to produce yellow phosphorus. The acidity of yellow phosphorus slag is calculated according to 0.8, and the ratio of entering the furnace is phosphorite: coke: silica = 1000:163:190, with an annual output of 20,000 tons of yellow phosphorus. The phosphorus furnace gas condensate in the production process is discharged into the hot water tank from the phosphorus tank for natural cooling, and then pumped to the scrubber tower in the hot section for condensation, and the excess condensate is directly discharged into the circulating sewage tank. The exhausted steam is not treated and silicon tetrafluoride is not recovered, which leads to the dispersion of exhausted steam in hot water tanks and circulating sewage pools, causing serious environmental pollution.

[...

Embodiment 2

[0058] The capacity of an electric furnace in a yellow phosphorus factory is 1×31500+1×35000KVA, with P 2 o 5 Content is 31%, SiO 2 Phosphorus concentrate pellets with a content of 13% and an F content of 1.75% are combined with coking coal and silica to produce yellow phosphorus. The acidity of yellow phosphorus slag is calculated according to 0.8, and the ratio of entering the furnace is phosphorus concentrate pellets: coke: silica = 1000:177:189, with an annual output of 35,000 tons of yellow phosphorus. The phosphorus furnace gas condensate in the production process is discharged into the hot water tank from the phosphorus tank for natural cooling, and then pumped to the scrubber tower in the hot section for condensation, and the excess condensate is directly discharged into the circulating sewage tank. The exhausted steam is not treated and silicon tetrafluoride is not recovered, which leads to the dispersion of exhausted steam in hot water tanks and circulating sewage ...

Embodiment 3

[0062] The electric furnace capacity of a large yellow phosphorus enterprise is 8×20000KVA, with P 2 o 5 content of 25%, SiO 2 Phosphate ore and coking coal with a content of 28% and a F content of 1.5% produce yellow phosphorus. The acidity of yellow phosphorus slag is calculated as 0.83, and the ratio of entering the furnace is phosphate rock: coke diced = 1000:152, with an annual output of 80,000 tons of yellow phosphorus. The phosphorus furnace gas condensate in the production process is discharged into the hot water tank from the phosphorus tank for natural cooling, and then pumped to the scrubber tower in the hot section for condensation, and the excess condensate is directly discharged into the circulating sewage tank. The exhausted steam is not treated and silicon tetrafluoride is not recovered, which leads to the dispersion of exhausted steam in hot water tanks and circulating sewage pools, causing serious environmental pollution.

[0063] According to the method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com