Method for converting rubdium and cesium in spodumene lithium-extracted slag into soluble salt

A spodumene, lithium slag technology, applied in chemical instruments and methods, rubidium/cesium/francium compounds, inorganic chemistry, etc. Loss of waste and other problems, to achieve the effect of low resource content, low acid and alkali consumption, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

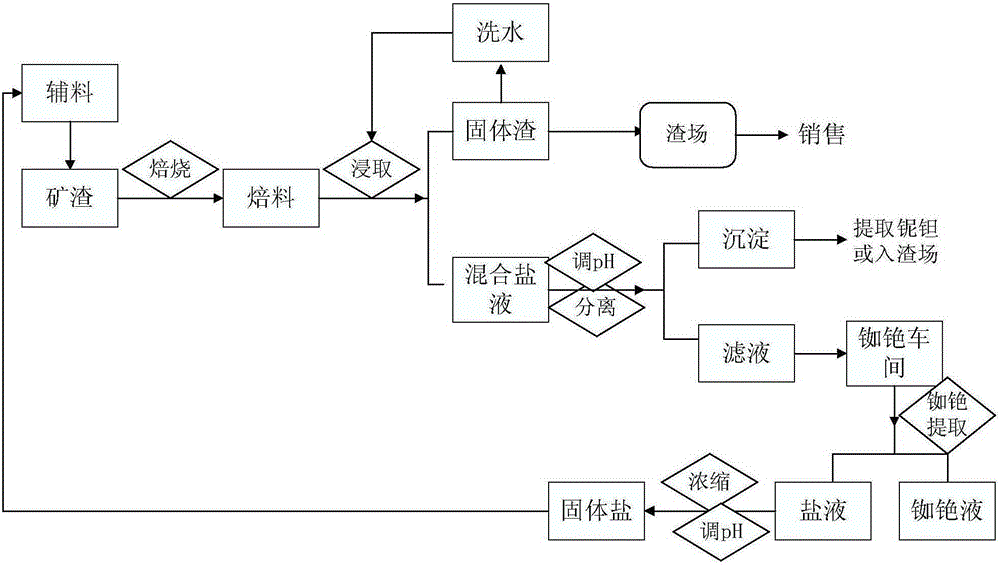

Method used

Image

Examples

Embodiment 1

[0056] (1) Weigh 2000g of slag after lithium extraction, add 300g of sodium chloride, 700g of calcium chloride, and 100g of calcium oxide and mix well.

[0057] The slag data is as follows (the same below):

[0058] Table 1

[0059] Li 2 o

Rb

Cs

K

Na

Ca

0.31%

0.11%

0.035%

0.44%

0.1%

2.31%

[0060] (2) Place the mixed material obtained in step (1) in a small-sized rotary kiln at a temperature of 800° C. and a roasting time of 60 minutes. After cooling, take it out to obtain a roasted material.

[0061] (3) Transfer the calcined material obtained in step (2) to a beaker, add 2480 mL of water, and stir at room temperature for 30 minutes to obtain a slurry.

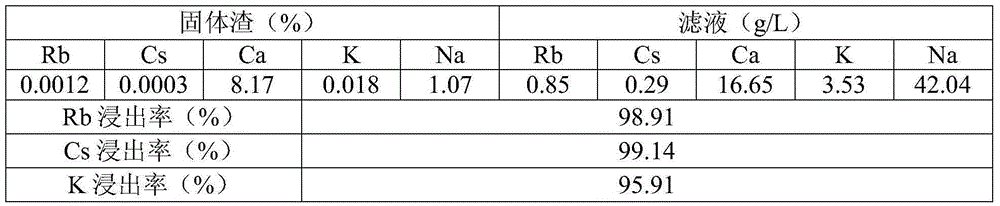

[0062] (4) Pass the slurry obtained in step (3) through a plate frame for solid-liquid separation, and wash with water 3 times. The solid residue was dried at 105°C. The filtrate and washing water are stored separately, the filtrate enters the next step, and...

Embodiment 2

[0069] (1) Weigh 2000g of slag after lithium extraction, add 700g of sodium chloride, 1300g of calcium chloride, and 100g of calcium oxide, and mix well.

[0070] (2) Put the mixed material obtained in step (1) in a small-sized rotary kiln, bake at 950° C. for 60 minutes, take it out after cooling, and obtain the roasted material.

[0071] (3) Transfer the calcined material obtained in step (2) to a beaker, add 4920 mL of water, and stir at room temperature for 30 minutes to obtain a slurry.

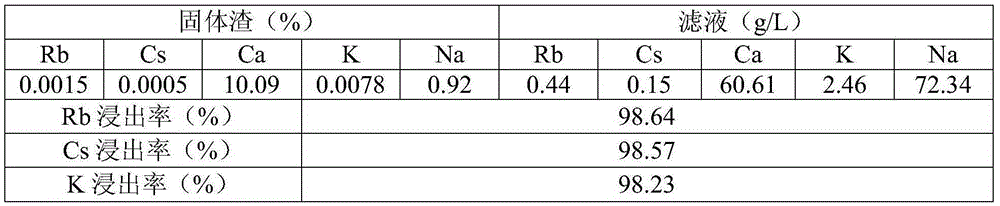

[0072] (4) Pass the slurry obtained in step (3) through a plate frame for solid-liquid separation, and wash with water 3 times. The solid residue was dried at 105°C. The filtrate and washing water are stored separately, the filtrate enters the next step, and the washing water returns to step (3) for use as leaching water. Gained solid slag and filtrate data are as follows:

[0073] table 3

[0074]

[0075] (5) Adjust the pH value of the solution obtained in step (4) to 11-14 with...

Embodiment 3

[0079] (1) Weigh 5000g of slag after lithium extraction, add 3000g of calcium chloride and 200g of calcium oxide, and mix well.

[0080] (2) Put the mixed material obtained in step (1) in a small-sized rotary kiln, bake at 800° C. for 60 minutes, take it out after cooling, and obtain the roasted material.

[0081] (3) Transfer the calcined material obtained in step (2) to a container, add 8200 mL of water, and stir at room temperature for 60 minutes to obtain a slurry.

[0082] (4) Pass the slurry obtained in step (3) through a plate frame for solid-liquid separation, and wash with water 3 times. The solid residue was dried at 105°C. The filtrate and washing water are stored separately, the filtrate enters the next step, and the washing water returns to step (3) for use as leaching water. Gained solid slag and filtrate data are as follows:

[0083] Table 4

[0084]

[0085] (5) Adjust the pH value of the solution obtained in step (4) to 11-14 with NaOH, filter out the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com