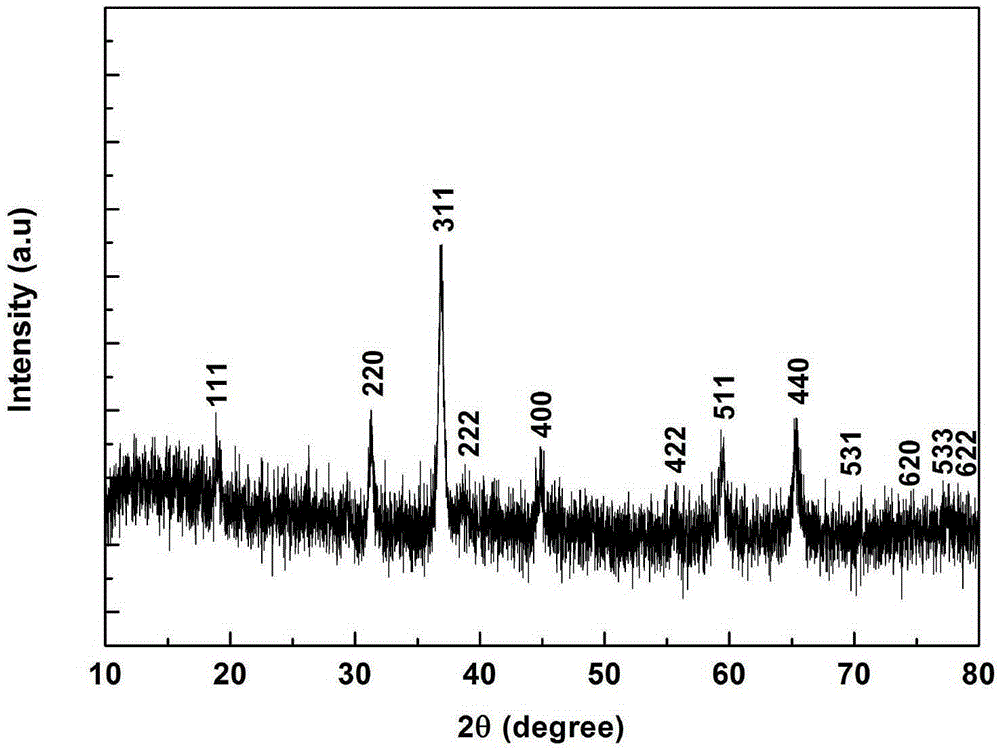

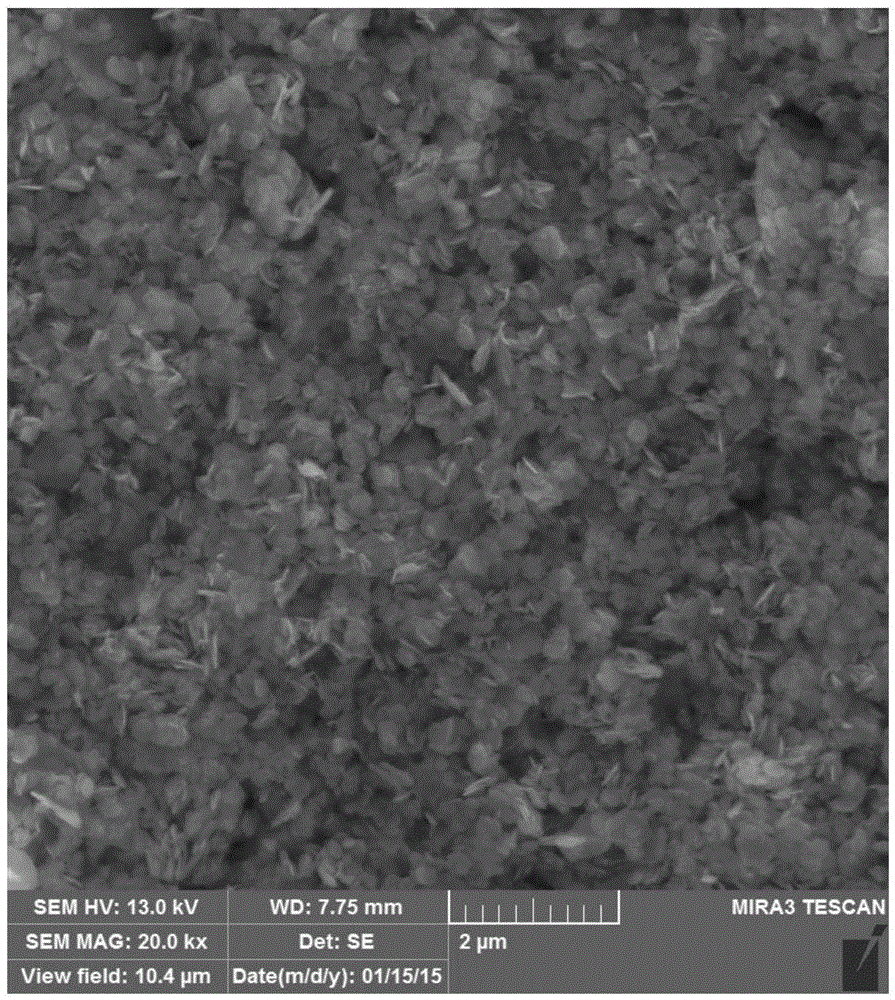

Method for preparing flaky nano CoO or Co3O4 through assistant microwave heating

A nano-sheet, microwave heating technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex synthesis methods and cumbersome post-processing, and achieve simple process flow and post-processing. Simple and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Add 0.04molCo(NO 3 ) 2 ·6H 2 O was dissolved in 200mL of deionized water to form a cobalt salt solution, and 20mg of ascorbic acid was added to the cobalt salt solution; 2mL of 25% concentrated ammonia water was dissolved in 38mL of deionized water to form a 40mL ammonia solution, and then 0.08molNaOH was added to the ammonia solution , to obtain NaOH-ammonia mixed alkali solution.

[0019] (2) At room temperature, evenly pour the NaOH-ammonia mixed alkali solution into the cobalt salt aqueous solution stirred at a constant speed at a flow rate of 1000mL / min. After the mixed alkali solution is completely added, microwave heating at 60°C and stir for 50 minutes.

[0020] (3) After the microwave reaction is completed, age the co-precipitate for 5 minutes, separate the solid from the liquid, wash with deionized water until neutral, put the filtrate in a vacuum drying oven, and dry it at 85°C for 12 hours to obtain a solid dry matter.

[0021] (4) Place the above-me...

Embodiment 2

[0023] (1) 0.02molCoCl 2 ·6H 2 O was dissolved in 80mL of deionized water to form a cobalt salt solution, and 8 mg of ascorbic acid was added to the cobalt salt solution; 0.05 mL of 25% concentrated ammonia water was dissolved in 9.95 mL of deionized water to form a 10 mL ammonia solution, and then added 0.04molNaOH to obtain NaOH-ammonia mixed alkali solution.

[0024] (2) At room temperature, the NaOH-ammonia mixed alkali solution was evenly poured into the cobalt salt aqueous solution stirred at a constant speed at a flow rate of 500mL / min. After the mixed alkali solution was added completely, it was heated by microwave at 45°C and stirred for 60 minutes.

[0025] (3) After the microwave reaction is completed, age the above co-precipitate for 5 minutes, separate the solid from the liquid, wash with deionized water until neutral, put the filtrate in a vacuum drying oven, and dry at 85°C for 6 hours to obtain a solid dry matter.

[0026] (4) Place the above-mentioned dried...

Embodiment 3

[0028] (1) 0.06molCoSO 4 ·7H 2 O was dissolved in 60mL of deionized water to make a cobalt salt solution, and 60mg of ascorbic acid was added to the cobalt salt solution; 4mL of 25% concentrated ammonia water was dissolved in 36mL of deionized water to form a 40mL ammonia solution, and then 0.12molNaOH was added to the ammonia solution , to obtain NaOH-ammonia mixed alkali solution.

[0029] (2) At room temperature, the NaOH-ammonia mixed alkali solution was evenly poured into the cobalt salt aqueous solution stirred at a constant speed at a flow rate of 2000mL / min. After the mixed alkali solution was completely added, microwave heating at 85°C and stirring for 20 minutes.

[0030] (3) After the microwave reaction is completed, age the above co-precipitate for 10 minutes, separate the solid from the liquid, wash with deionized water until neutral, put the filtrate in a vacuum drying oven, and dry at 100°C for 2 hours to obtain a solid dry matter.

[0031] (4) Place the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com