Method for preparing chlorophyll sodium copper from mulberry leaves

A technology of sodium copper chlorophyllin and mulberry leaves, applied in the direction of organic chemistry, can solve the problems of shortening the reaction time, decolorization of the alcohol extract, etc., and achieve the effects of shortening the reaction time, easy separation, and good commercial prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

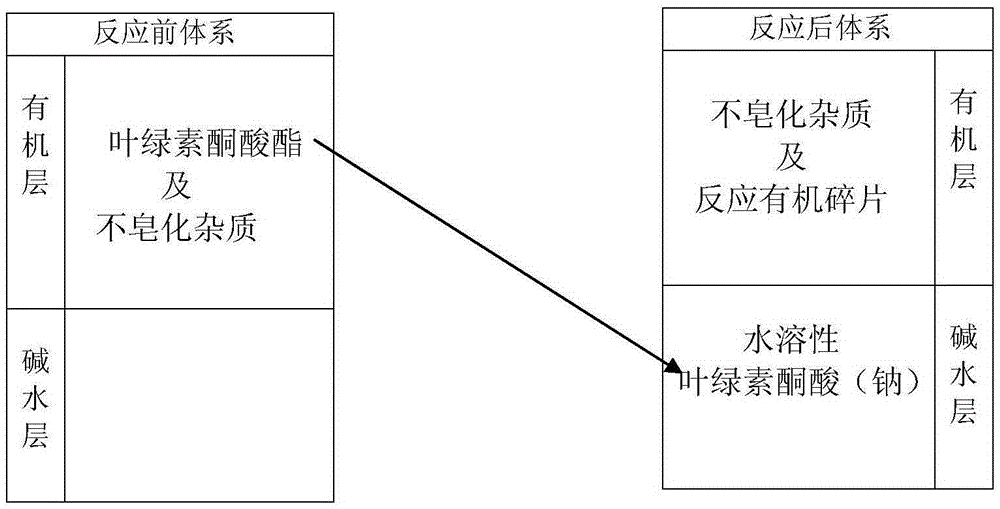

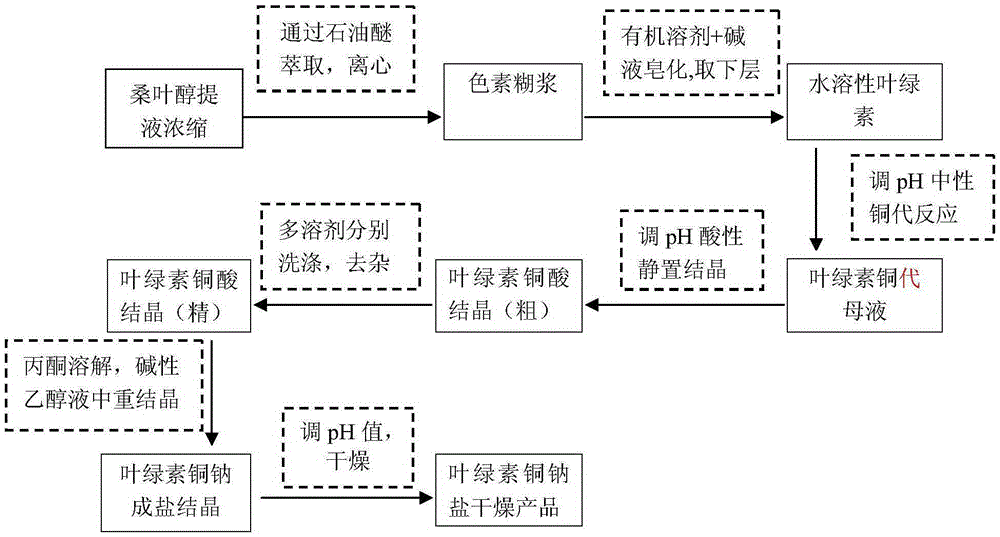

Method used

Image

Examples

Embodiment 1

[0056] (1) Dry mulberry leaf powder is extracted by adding 70v / v% ethanol at a mass ratio of 1:10 to obtain an alcohol extract, which is concentrated to 1 / 15 of the original volume, and centrifuged at 4000rpm for 3 minutes in a low-speed centrifuge to obtain the upper pigment paste Slurry and lower liquid, wherein the lower liquid accounts for 80% of the total volume;

[0057] (2) The lower layer liquid is extracted twice with petroleum ether at a volume ratio of 1:1, and the liquid is separated to obtain the depigmented mulberry leaf alcohol extract (for other purposes), and petroleum ether extract;

[0058] (3) The petroleum ether extract is at a temperature of 65°C and a vacuum of 0.08MPa, and the petroleum ether is recovered by rotary evaporation to obtain a substance after the petroleum ether is recovered, which is combined with the pigment paste obtained by centrifugation, and the mixed pigment paste obtained at this time is The solid content is 10wt%;

[0059] (4) Add ...

Embodiment 2

[0069] (1) Dry mulberry leaf powder is extracted by adding 70v / v% ethanol at a mass ratio of 1:15 to obtain an alcohol extract, which is concentrated to 1 / 20 of the original volume, and centrifuged at 3000rpm for 3 minutes in a low-speed centrifuge to obtain the upper pigment paste Slurry and lower liquid, wherein the lower liquid accounts for 90% of the total volume;

[0070] (2) The lower liquid was extracted 3 times with petroleum ether at a volume ratio of 2:1, and the liquid was separated to obtain the depigmented mulberry leaf alcohol extract (for other purposes), and petroleum ether extract;

[0071] (3) The petroleum ether extract is at a temperature of 65°C and a vacuum of 0.08MPa, and the petroleum ether is recovered by rotary evaporation to obtain a substance after the petroleum ether is recovered, which is combined with the pigment paste obtained by centrifugation, and the mixed pigment paste obtained at this time is The solid content is 12wt%;

[0072] (4) Add pe...

Embodiment 3

[0082] (1) Dry mulberry leaf powder is extracted by adding 80v / v% ethanol at a mass ratio of 1:20 to obtain an alcohol extract. The alcohol extract is concentrated to 1 / 15 of the original volume, and centrifuged at 100rpm in a low-speed centrifuge for 4 minutes to obtain the upper pigment paste Slurry and lower liquid, wherein the lower liquid accounts for 85% of the total volume;

[0083] (2) The lower liquid was extracted 4 times with petroleum ether at a volume ratio of 1:1, and the liquid was separated to obtain the depigmented mulberry leaf alcohol extract (for other purposes), and petroleum ether extract;

[0084] (3) The petroleum ether extract is at a temperature of 65°C and a vacuum of 0.08MPa, and the petroleum ether is recovered by rotary evaporation to obtain a substance after the petroleum ether is recovered, which is combined with the pigment paste obtained by centrifugation, and the mixed pigment paste obtained at this time is The solid content rate is 15wt%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com