Method of smelting and recycling tin in abandoned circuit board powder through multi-component mixed molten salt under alkaline environment

A waste circuit board and multi-component technology, applied in the direction of improving process efficiency, can solve the problems of polluting gas, environmental pollution, waste of metal particles, etc., and achieve the effect of reducing melting temperature, optimizing melting conditions and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for recovering tin in waste circuit board powder by alkaline smelting of multiple mixed molten salts of the present invention comprises the following steps:

[0031] (1) Low-temperature oxidation smelting: take 100g of waste circuit board powder shown in Table 1, mix evenly with 270g of multi-element alkaline medium (NaOH120g, KOH150g), put it into a special nickel crucible, and smelt it at 190°C. The smelting process Oxygen was passed into the medium, and the smelting was carried out for 60 minutes to obtain the smelted product;

[0032] (2) Water immersion dissolution: the smelting product obtained in step (1) is soaked and dissolved in water at a liquid-solid mass ratio of 7:1, and filtered to obtain leaching solutions containing tin, zinc, aluminum, etc. and leaching slag of other precious metals;

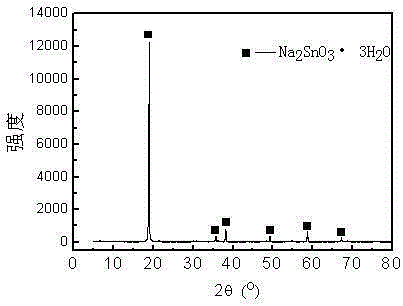

[0033] (3) Evaporation and crystallization: Add NaOH to the leachate obtained in step (2) to keep the total alkali mass concentration of the leachate at 400g / L,...

Embodiment 2

[0037] A method for recovering tin in waste circuit board powder by alkaline smelting of multiple mixed molten salts of the present invention comprises the following steps:

[0038] (1) Low-temperature oxidation smelting: Take 100g of waste circuit board powder shown in Table 1 and 400g of multi-element alkaline medium (150g of LiCl, 150g of KCl, 100g of NaOH), mix evenly, put it into a special nickel crucible, and melt it at 200°C. Oxygen was introduced during the smelting process, and smelted for 50 minutes to obtain the smelted product;

[0039] (2) Water immersion dissolution: the smelting product obtained in step (1) is soaked and dissolved in water at a liquid-to-solid mass ratio of 5:1, and filtered to obtain leaching solutions containing tin, zinc, aluminum, etc. and leaching slag of other precious metals;

[0040] (3) Evaporation and crystallization: add KOH to the leachate obtained in step (2) to keep the total alkali mass concentration of the leachate at 350g / L, the...

Embodiment 3

[0042] A method for recovering tin in waste circuit board powder by alkaline smelting of multiple mixed molten salts of the present invention comprises the following steps:

[0043](1) Low-temperature oxidation smelting: take 100g of waste circuit board powder shown in Table 1, mix evenly with 270g of multi-element alkaline medium (NaOH100g, KOH120g, NaCl50g), put it into a special nickel crucible, and melt it at 150°C. Oxygen is introduced during the smelting process, and smelted for 30 minutes to obtain the smelted product;

[0044] (2) Water immersion dissolution: the smelting product obtained in step (1) is soaked and dissolved in water at a liquid-solid mass ratio of 8:1, and filtered to obtain a leach solution containing tin, zinc, aluminum, etc., and leaching slag of other precious metals;

[0045] (3) Evaporation and crystallization: add NaOH to the leaching solution obtained in step (2), so that the total alkali mass concentration of the leaching solution is kept at 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com