Preparation method of isotropic graphite material

A graphite material, isotropic technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high processing cost and complicated processing technology, and achieve the effect of less processing equipment, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 20g polyvinyl alcohol organic polymer into 2L water and stir for 30 minutes;

[0024] (2) Add 400g of needle coke into the solution containing polyvinyl alcohol and stir for 30 minutes;

[0025] (3) Add 12.7g of ferrous chloride into the above water solvent and stir for half an hour;

[0026] (4) While stirring, add 500mL, 0.3mol / L sodium hydroxide dropwise at 5mL / min to the mixed solution, and stir for 2 hours;

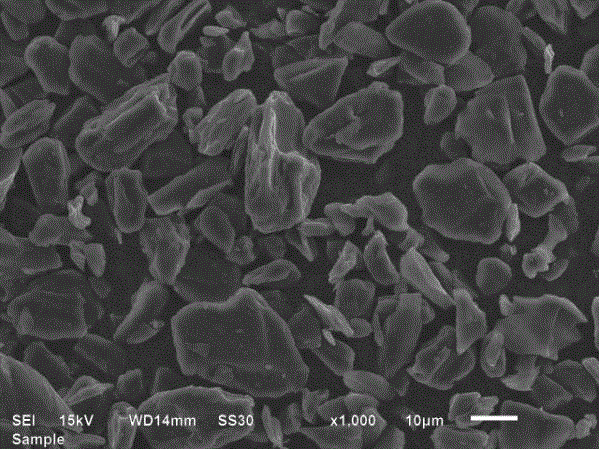

[0027] (5) Filter the above solution, and dry it at 100°C for 5 hours; then raise the temperature to 2800°C at a rate of 3°C / min under the protection of argon atmosphere, keep it warm for 20 hours, and cool it down to below 100°C naturally, take out the material, crush, After sieving, the isotropic graphite lithium ion battery negative electrode material can be obtained.

Embodiment 2

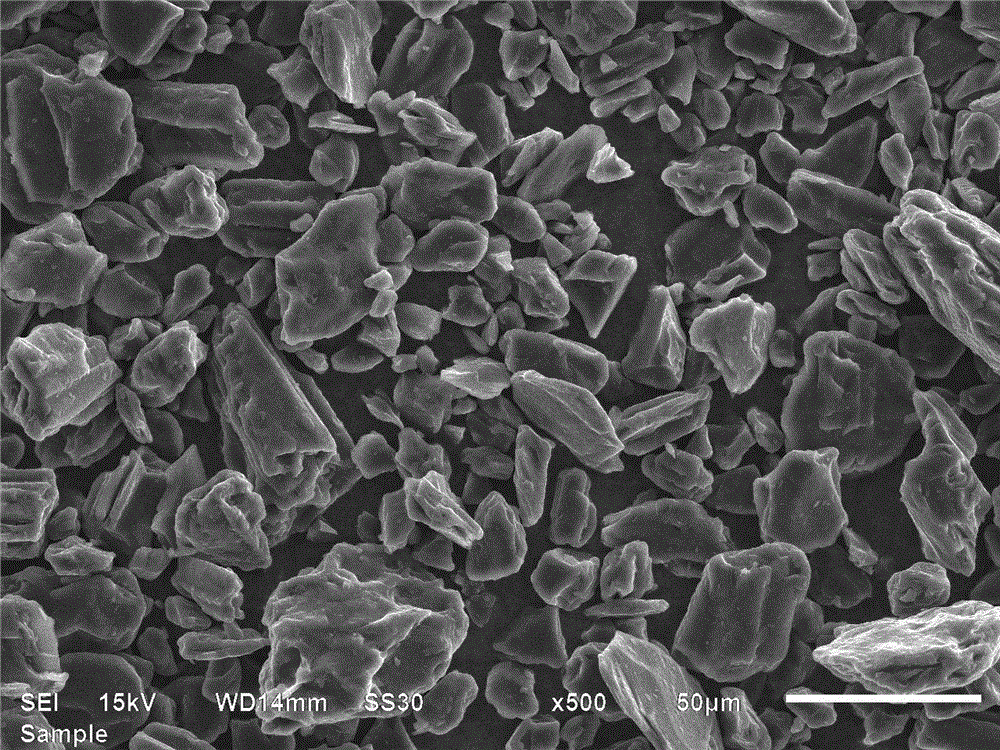

[0029] (1) Add 10g polyvinyl alcohol organic polymer into 2L water and stir for 30 minutes;

[0030] (2) Add 300g of petroleum coke into the solution containing polyvinyl alcohol and stir for 30 minutes;

[0031] (3) Add 12.7g of ferrous chloride into the above water solvent and stir for half an hour;

[0032] (4) While stirring, add 500mL, 0.2mol / L sodium hydroxide dropwise at 5mL / min to the mixed solution, and stir for 2 hours;

[0033] (5) Filter the above solution, and dry it at 100°C for 5 hours; then raise the temperature to 2800°C at a rate of 5°C / min under the protection of argon atmosphere, keep it warm for 25 hours, and then cool it down to below 100°C naturally, take out the material, crush, After sieving, the isotropic graphite lithium ion battery negative electrode material can be obtained.

Embodiment 3

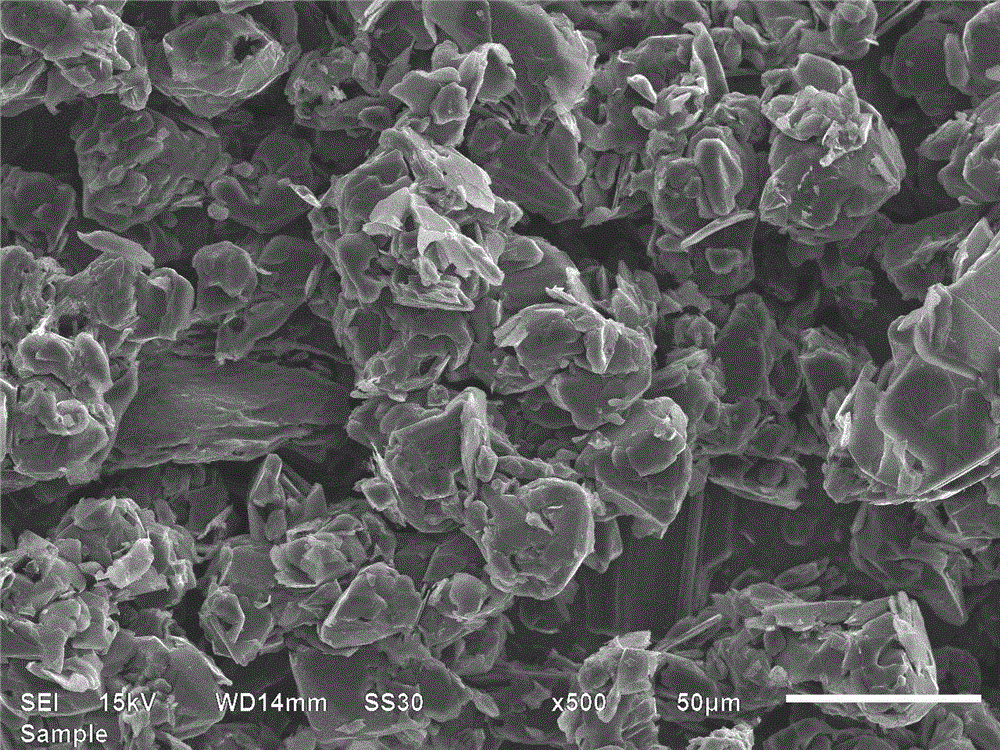

[0035] (1) Add 15g of polyvinylpyrrolidone organic polymer, 500g of petroleum coke, and 26.3g of nickel sulfate into 2L of water and stir for 3 hours;

[0036] (2) While stirring, add 500mL, 0.3mol / L potassium hydroxide dropwise at 3mL / min to the mixed solution, and stir for 2 hours;

[0037] (3) Filter the above solution and dry it at 100°C for 5 hours; then raise the temperature to 3000°C at a rate of 5°C / min under the protection of argon atmosphere, keep it warm for 20 hours, and cool it down to below 100°C naturally, take out the material, crush, After sieving, the isotropic graphite lithium ion battery negative electrode material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com