Processing method of ripe Puer tea with low caffeine content

A technology of low caffeine and processing method, which is applied in the direction of tea processing before extraction, etc., can solve the problems of paroxysmal convulsions, bone tremors, damage to internal organs, etc., and achieve the effect of easy operation and simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The cultivation of embodiment 1 polypolymycetes powder

[0028] The seed culture medium of 5.0kg rice, 1.5kg glucose and 5.5L distilled water was sterilized at 121°C for 15min and then inoculated with 1000mL10 8 CFU / mL of Aspergillus polypolyps suspension. Place them in a constant temperature and humidity chamber at 27°C and 85% humidity. After the colonies are mature, dry them at a constant temperature of 55°C, and grind them into powder under aseptic conditions. Take 1g of bacterial powder and add 9mL sterile saline to 10 -1 、10 -2 、10 -3 、10 -4 、10 -5 、10 -6 、10 -7 , 10 -8 , 10 -9 Equal to different dilution multiples, use a pipette gun to draw 0.2mL of bacterial solution and spread it evenly on the PDA medium. After culturing in a constant temperature and humidity test box for 3 days, observe the growth of bacterial colonies.

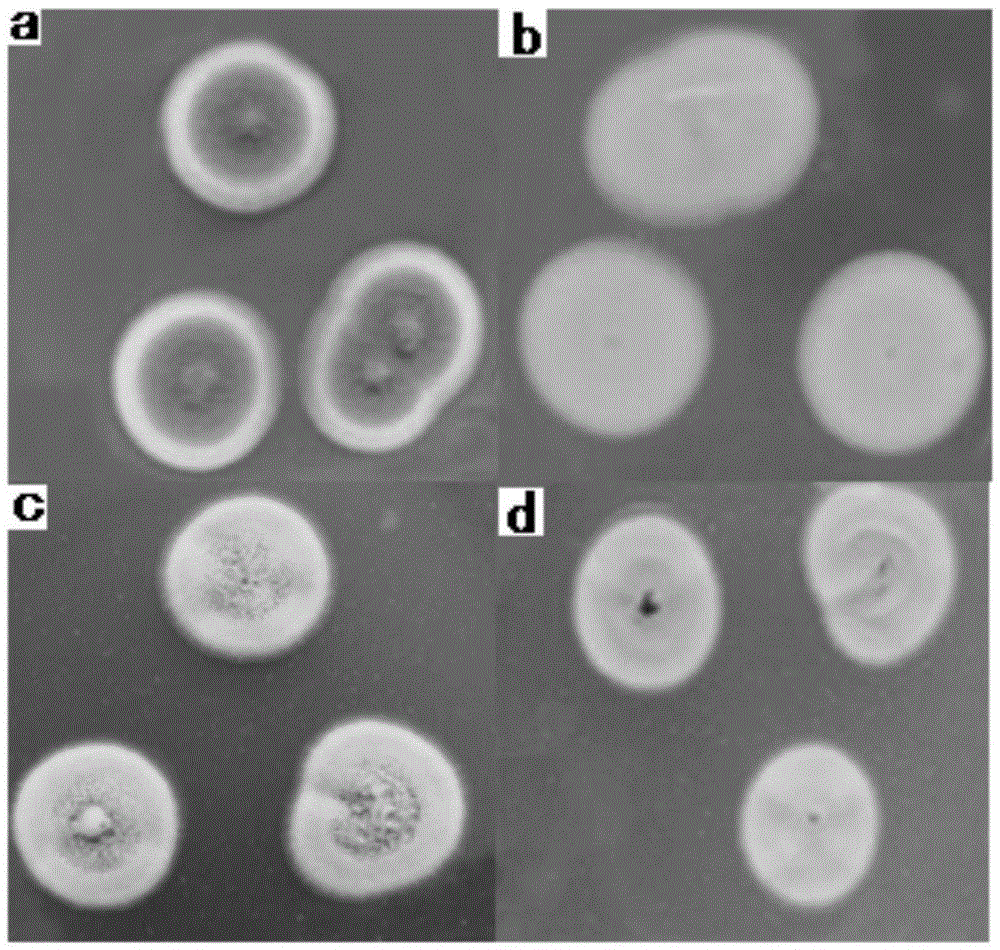

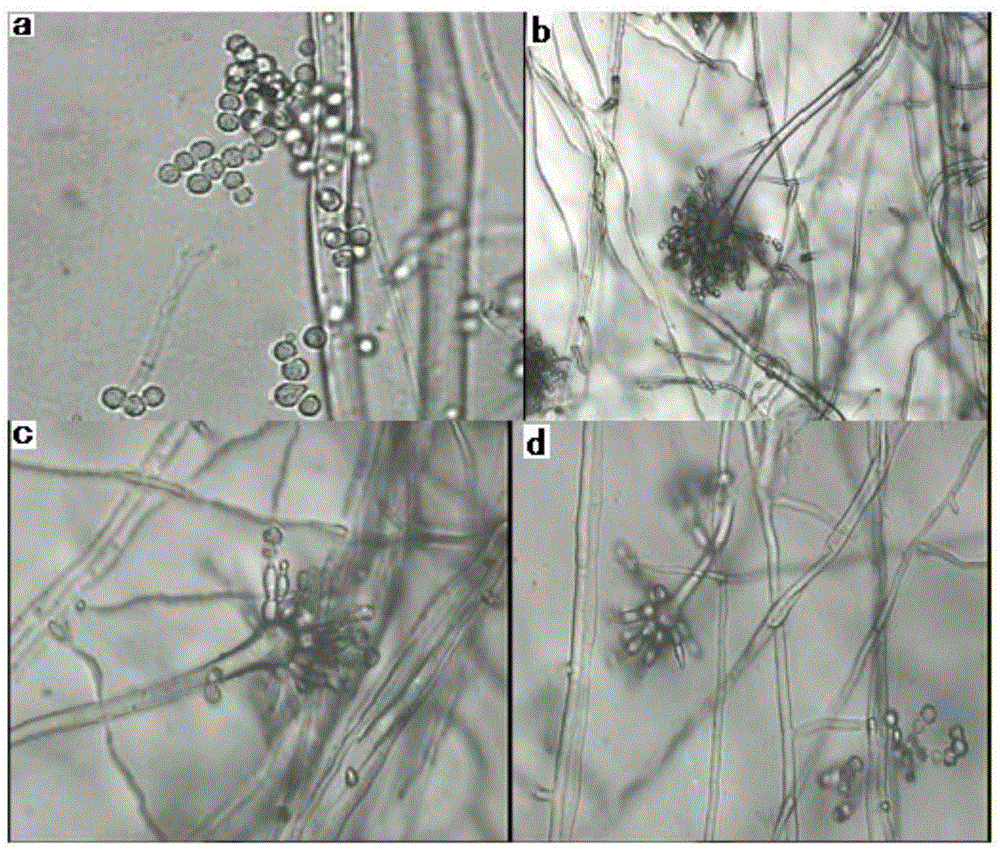

[0029] Spread Aspergillus polypolyphaga solution on PDA medium and Chapei medium, and cultivate it under constant temperature and...

Embodiment 2

[0032] The determination of the quantity of embodiment 2 Polypolymycetes species

[0033] According to the sampling method, take 3 samples of Aspergillus polypolyphaga powder, divided into No. 1 sample, No. 2 sample, and No. 3 sample, and repeat the measurement twice for each sample. Cultivate under constant temperature and humidity conditions for 3 days to measure the number of colonies at each dilution, and 10 -6 , 10 -7 , 10 -8 , 10 -9 The records of the number of Aspergillus polypolymosa colonies and the number of miscellaneous colonies under the dilution are shown in Table 1. 9 ~4.30×10 10 , with an average value of 1.25×10 10 , Miscellaneous bacteria colonies accounted for 0.41% to 7.69% of Aspergillus polypolyphagium colonies, with an average of 3.59%. Miscellaneous bacteria were preliminarily judged as Penicillium, yeast, and Aspergillus niger according to the "Handbook of Fungal Identification", "History of Fungi of China", and "Handbook of Microbiological Exper...

Embodiment 3

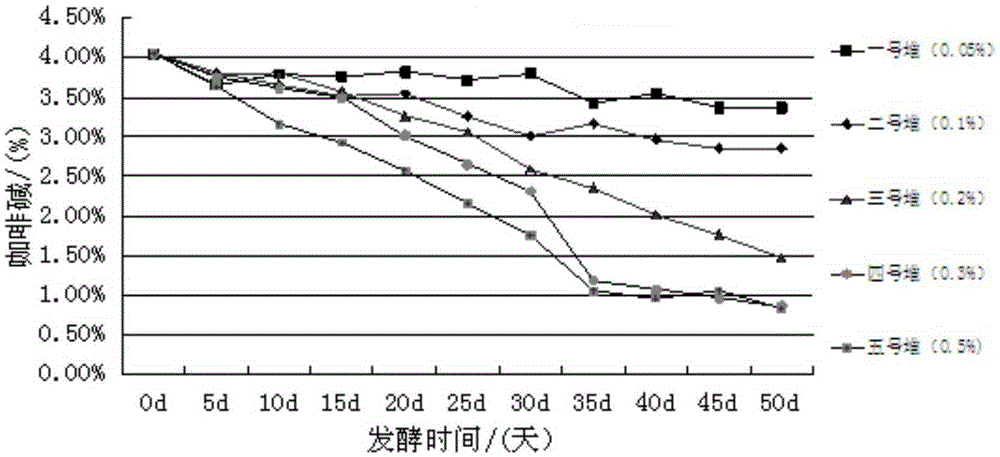

[0036] Embodiment 3 Pu'er tea stack fermentation

[0037]Take 2000kg of sun-dried green hair tea and add 850kg of drinking water to make the tidal water volume 37%. Add polypolymycetes powder 1.0kg, 2.0kg, 4.0kg, 6.0kg, 10.0kg successively (inoculum size is 0.05%, 0.1%, 0.2%, 0.3%, 0.5%) successively. After mixing well, they are numbered 1-5. Turn over the pile and take samples every five days. Measure the pile temperature before turning over. And add the right amount of drinking water.

[0038] As shown in Table 2, during the stacking fermentation process of sun-dried green hair tea, the temperature showed a change law that first increased and then decreased. Temperature and tidal volume are related to the degree of fermentation. In the early stage of fermentation, the temperature is relatively high, usually maintained between 40-50°C, and in the middle and late stages of fermentation, the temperature is slightly lower, and mostly maintained between 35-45°C. In view of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com