Desulphurization synergist for wet-method smoke desulphurization system of fire plant

A technology for wet flue gas desulfurization and thermal power plants, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as acid rain, acid fog, sulfur dioxide emissions, and human carcinogenicity, and accelerate absorption. and conversion process, reducing dosage, and improving the effect of existing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

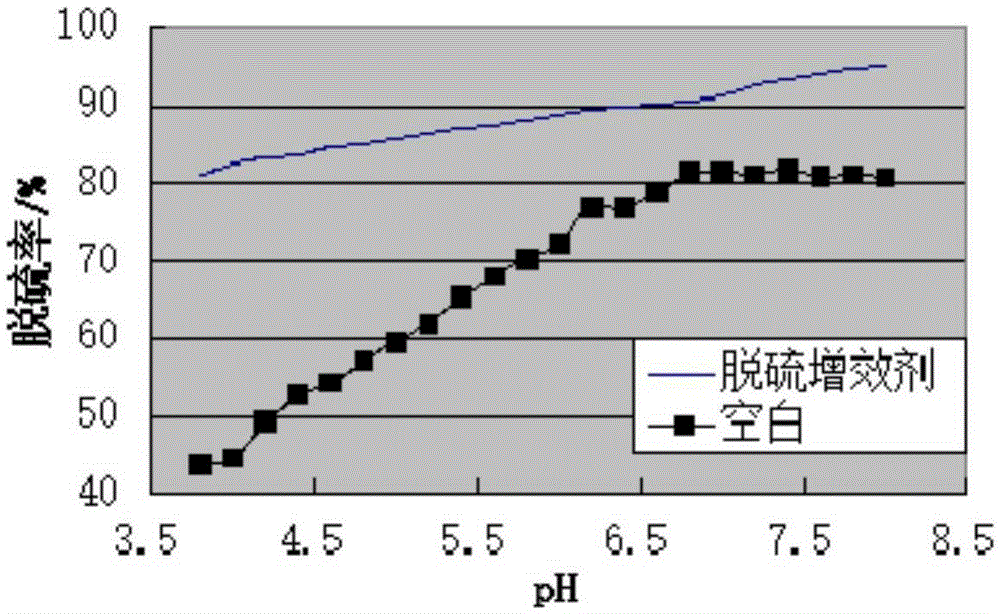

[0027] Embodiment one: a kind of synergist of wet flue gas desulfurization of the present invention, by mass percentage, its composition and content are as follows: sodium dodecanoate 60%, sodium chloride 20%, sodium benzoate 15%, sodium oxide 5% %. The desulfurization synergist can be obtained by mixing sodium dodecanoate, sodium chloride, sodium benzoate and calcium oxide and stirring evenly. Such as figure 1 As shown, under normal operating conditions, when the operating temperature, dosage and intake air concentration are constant, the desulfurization efficiency after using the desulfurization synergist is significantly higher than that of the blank control data without using the chemical agent under the same pH conditions.

Embodiment 2

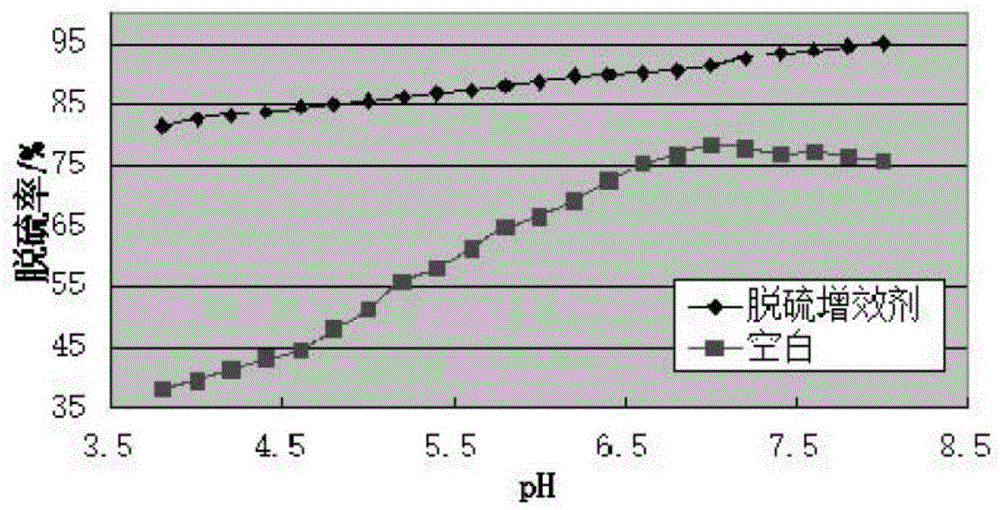

[0028] Embodiment two: a kind of wet flue gas desulfurization synergist of the present invention, by mass percentage, its composition and content are as follows: sodium octadecanoate 40%, potassium carbonate 40%, sodium terephthalate 15%, tetroxide Tri iron 5%. The desulfurization synergist can be obtained by mixing sodium octadecanoate, sodium carbonate, sodium terephthalate and ferric iron tetroxide and stirring evenly. Such as figure 2 As shown, under normal operating conditions, when the operating temperature, dosage and intake air concentration are constant, the desulfurization efficiency after using the desulfurization synergist is significantly higher than that of the blank control data without using the chemical agent under the same pH conditions.

Embodiment 3

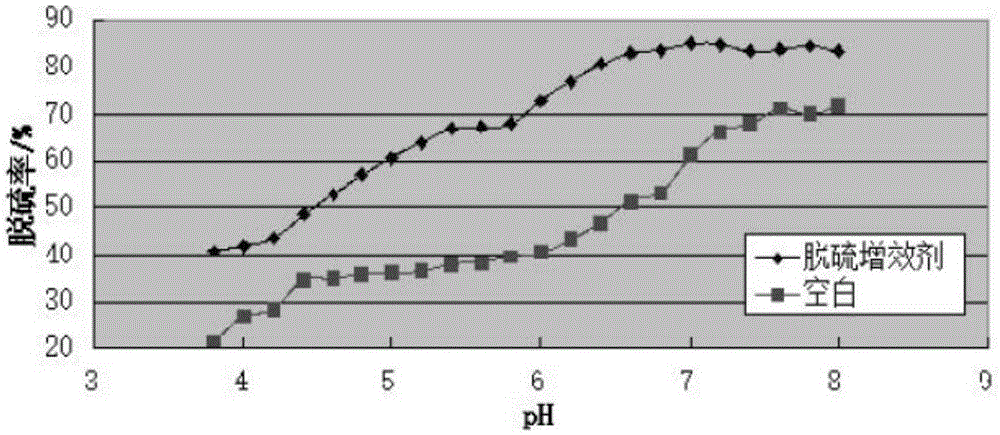

[0029] Embodiment three: a kind of wet flue gas desulfurization synergist of the present invention, by mass percentage, its composition and content are as follows: sodium myristate 50%, potassium oxalate 40%, sodium dodecylbenzene potassium 5%, Iron Tetroxide 5%. The desulfurization synergist can be obtained by mixing sodium myristate, potassium oxalate, sodium dodecyl benzoate and ferric iron tetroxide and stirring evenly. Such as image 3 As shown, under normal operating conditions, when the operating temperature, dosage and intake air concentration are constant, the desulfurization efficiency after using the desulfurization synergist is significantly higher than that of the blank control data without using the chemical agent under the same pH conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com