Hierarchical porous silica-alumina zeolite molecular sieve, synthetic method and application of hierarchical porous silica-alumina zeolite molecular sieve

A technology of silica-alumina zeolite and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, molecular sieve catalyst, chemical instrument and method, etc., can solve the problems of expensive, complicated process flow, and the feasibility of large-scale production scale-up, etc., Achieve high acidity, high hydrothermal stability, good catalytic performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

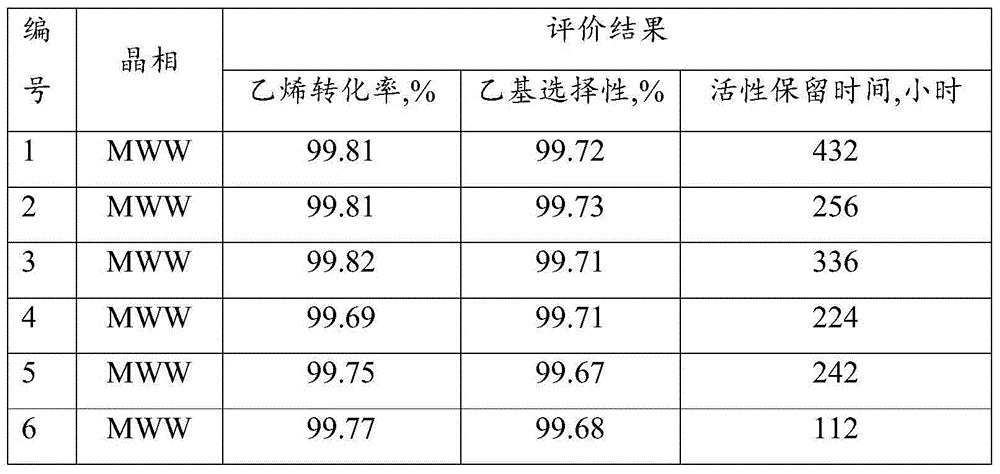

Embodiment 1

[0038] Add an aqueous solution containing 448g of sucrose to 128g of white carbon black, immerse in equal volume at room temperature for 8 hours, and then carbonize in a tube furnace with dry high-purity nitrogen after drying. The carbonization temperature is 750°C and the carbonization time is After 6 hours, the silicon carbide source sample A was obtained, and its SiO 2 The content is 40%.

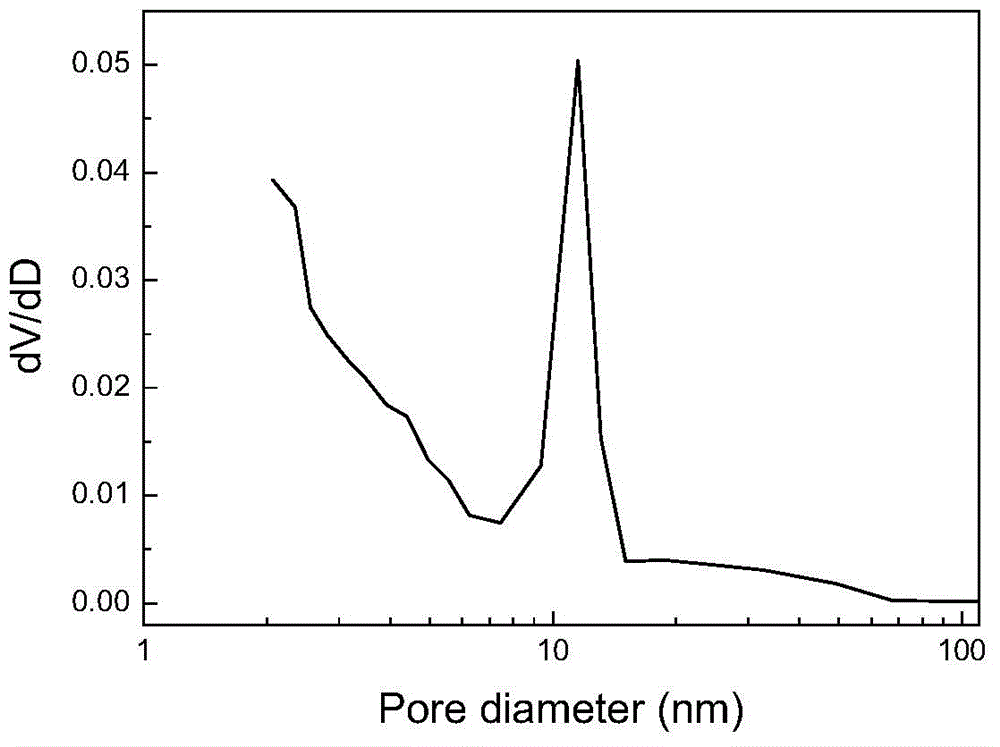

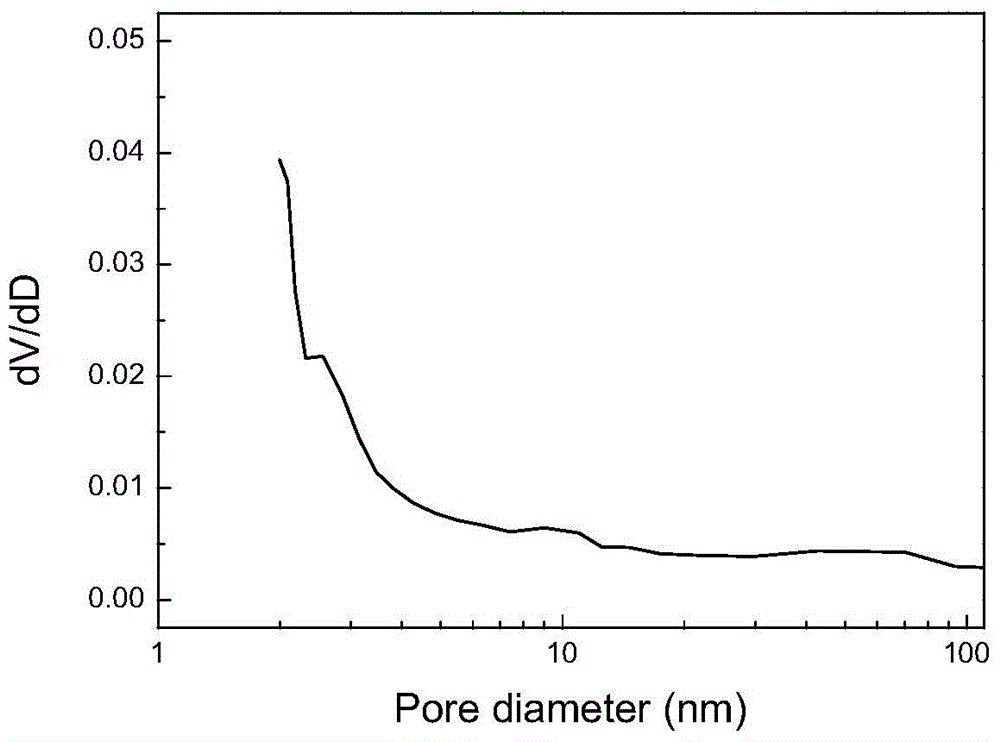

[0039]Weigh 26.20g of silicon carbide source A, add 61.58g of water and 2.10g of sodium hydroxide, stir at 50°C for 3 hours, then add 1.94g of aluminum sulfate and 7.80g of template agent hexamethyleneimine in sequence, and the material is gelled Formulation for SiO 2 :0.0286Al 2 o 3 :0.10Na 2 O:20.0H 2 O: 0.45 hexamethyleneimine. The crystallization process was carried out in a 100mL crystallization kettle, the crystallization temperature was 175°C, the crystallization time was 48 hours, and the crystallization mode was dynamic. The crystallized product is prepared after washing,...

Embodiment 2

[0042] Weigh 26.20g of silicon carbide source A, add 36.57g of water and 2.38g of sodium hydroxide, stir at 50°C for 3 hours, then add 4.66g of aluminum sulfate and 5.20g of templating agent hexamethyleneimine in sequence, and the material is gelled Formulation for SiO 2 :0.040Al 2 o 3 :0.05Na 2 O:12.5H 2 O: 0.30 hexamethyleneimine. The crystallization process was carried out in a 100mL crystallization kettle, the crystallization temperature was 175°C, the crystallization time was 48 hours, and the crystallization mode was dynamic. The crystallized product is prepared after washing, drying and roasting, and the number is 2. In terms of specific surface area percentage, the proportion of mesopores (2nm≤pore diameter<100nm) is 57%, and the proportion of micropores (0.5nm<pore diameter<2nm) is 43%.

Embodiment 3

[0044] Weigh 26.20g of silicon carbide source A, add 38.115g of water and 1.40g of sodium hydroxide, stir at 50°C for 3 hours, then add 1.94g of aluminum sulfate and 6.69g of templating agent hexahydropyridine in sequence, and the gelling formula of the material is SiO 2 :0.0167Al 2 o 3 :0.05Na 2 O:12.5H 2 O: 0.45 hexahydropyridine. The crystallization process was carried out in a 100mL crystallization kettle, the crystallization temperature was 175°C, the crystallization time was 48 hours, and the crystallization mode was dynamic. The crystallized product is prepared after washing, drying and roasting, and the number is 3. In terms of specific surface area percentage, the proportion of mesopores (2nm≤pore diameter<100nm) is 63%, and the proportion of micropores (0.5nm<pore diameter<2nm) is 37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com