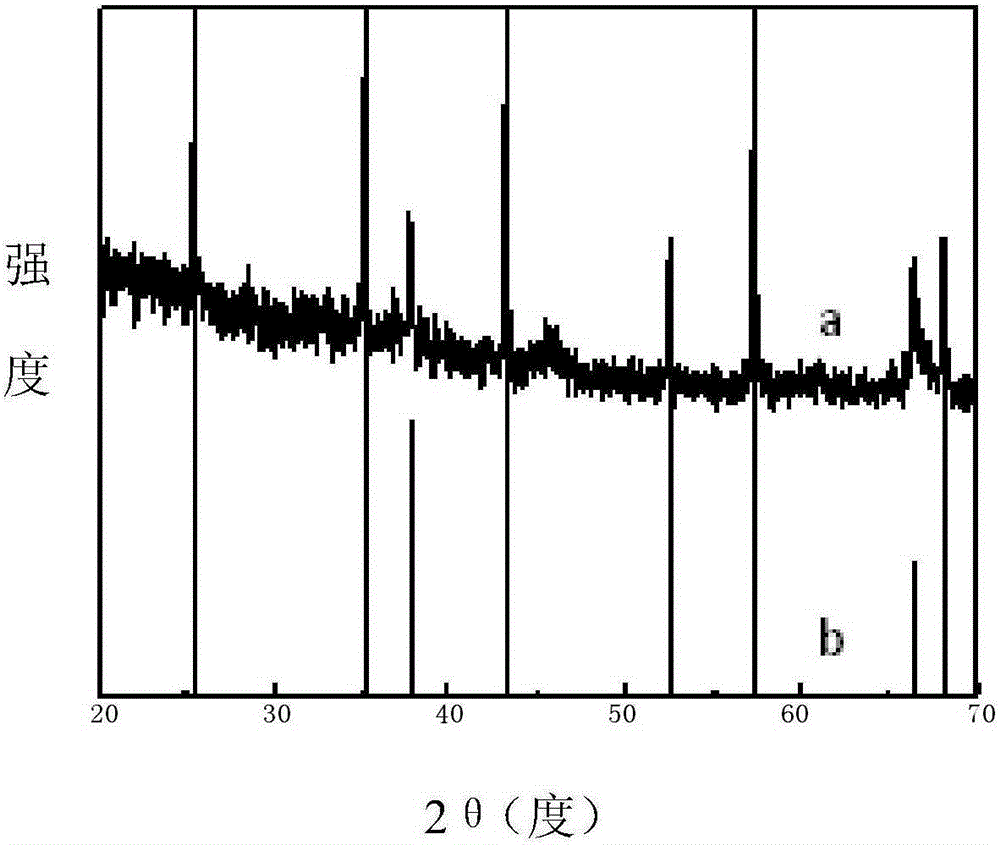

Method for manufacturing nanometer alumina by using precipitate generated from aluminum-air battery discharge

A nano-alumina and air battery technology, applied in the energy field, achieves the effects of simple preparation process, reduced operating cost, and realization of waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

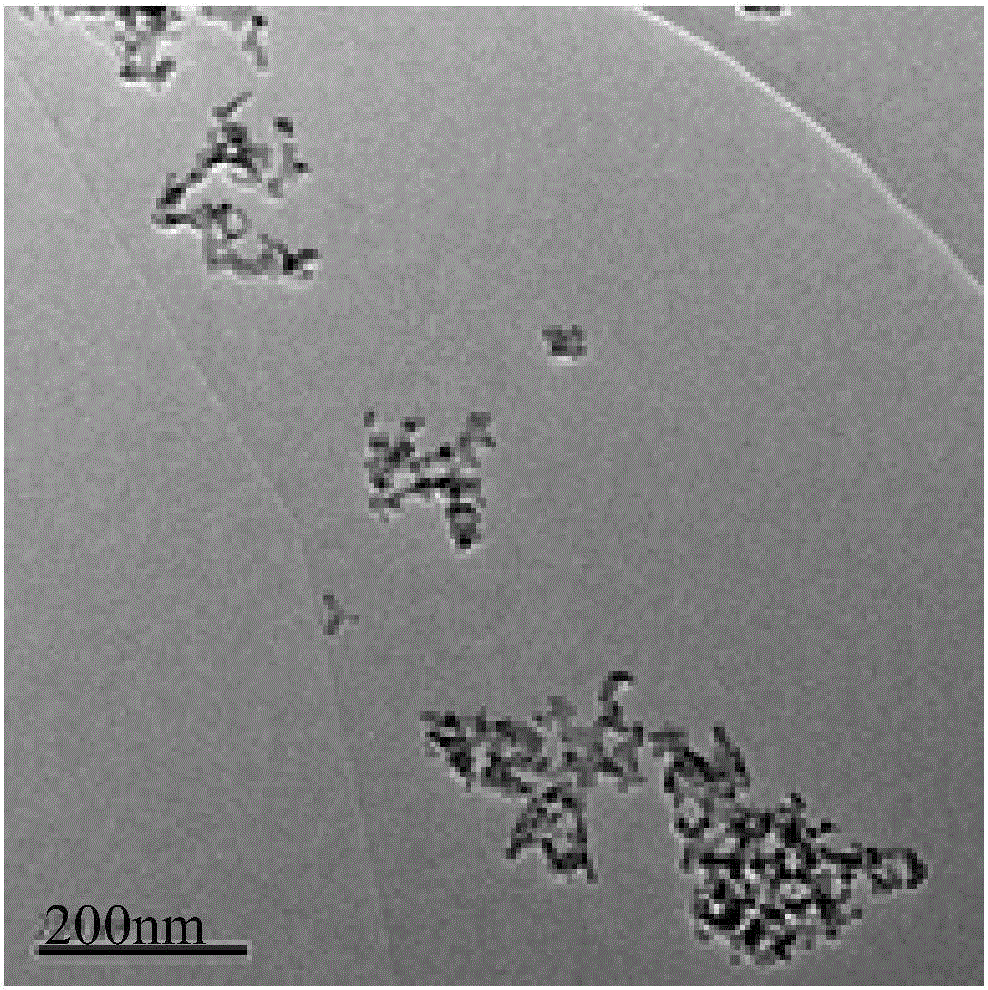

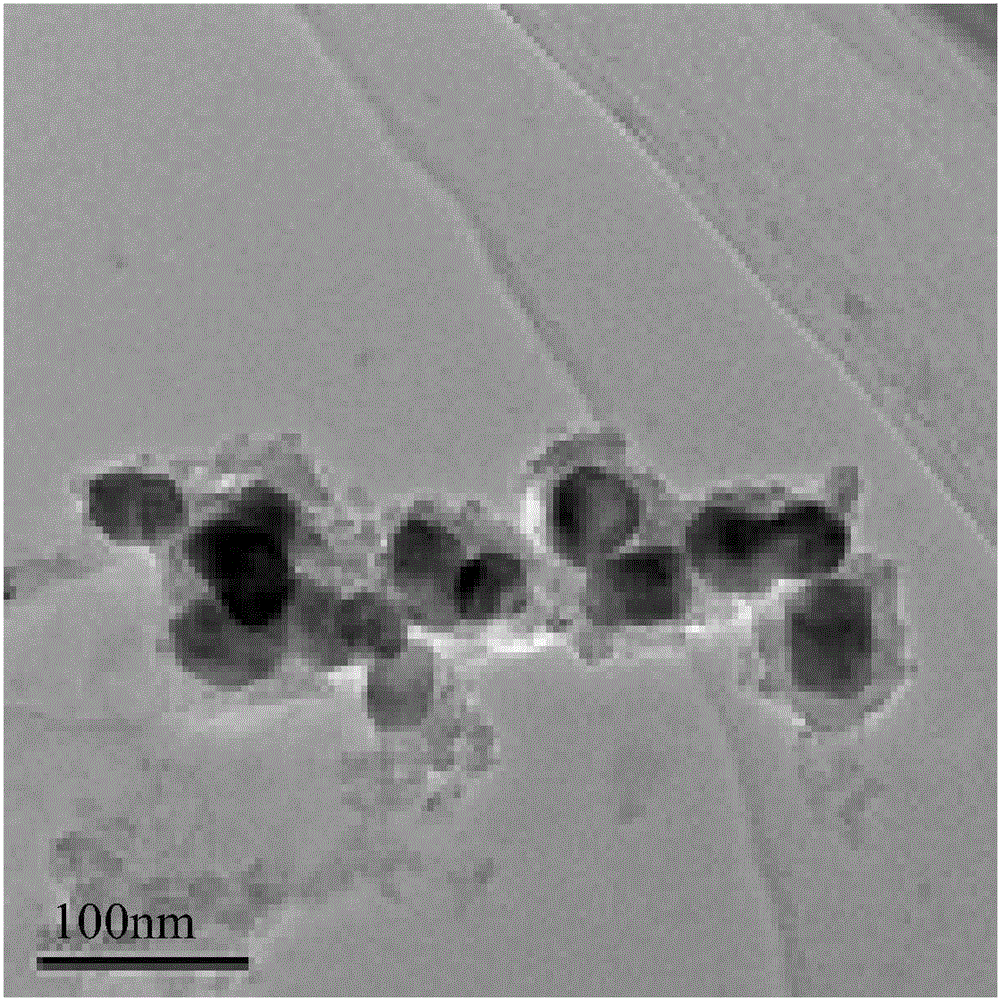

[0030] Embodiment 1: Produce nano-alumina (α-Al 2 o 3 ) method, comprising the steps of:

[0031] 1) Put an appropriate amount of the precipitate generated by the discharge of the aluminum-air battery into the container, add distilled water and stir thoroughly, and then let it stand still. Place, and then remove the supernatant in the container after precipitation; repeat the above operation several times until the pH value of the supernatant is close to neutral, after cleaning, remove the supernatant, filter, and dry to obtain a precipitate;

[0032] 2) Weigh 16 grams of the precipitate obtained in step 1) and put it into a container, then add 200 ml of sulfuric acid aqueous solution (which contains 72 grams of pure sulfuric acid) into the container, heat and stir to dissolve the precipitate, and filter to obtain an aqueous aluminum sulfate solution; The weight ratio of adding pure sulfuric acid to the precipitate described in step 1) is 4.5:1

[0033] 3) Add 26 grams of a...

Embodiment 2

[0042] Nano-alumina (α-Al 2 o 3 ) method, comprising the steps of:

[0043] 1) with embodiment 1 step 1);

[0044] 2) Take by weighing 3 grams of the precipitate obtained in step 1) and put it into a container, then add an aqueous sulfuric acid solution (containing 16 grams of pure sulfuric acid) into the container, heat and stir to dissolve the precipitate, filter to obtain an aqueous aluminum sulfate solution; add The weight ratio of pure sulfuric acid to precipitate is 5.3:1

[0045] 3) Put 9 grams of ammonium carbonate into a beaker, add 100ml of distilled water, stir to dissolve it, adjust the pH value to 9 with ammonia water to obtain an aqueous ammonium carbonate solution, and add the aluminum sulfate aqueous solution obtained in step 2) to the pH value while stirring. In the ammonium carbonate aqueous solution of 9, a white precipitate is generated, filtered, and dried to obtain ammonium aluminum carbonate; the weight ratio of adding ammonium carbonate to the precip...

Embodiment 3

[0053] Nano-alumina (α-Al 2 o 3 ) method, comprising the steps of:

[0054] 1), 2) with embodiment 2 1), 2);

[0055] 3) the ammonium carbonate aqueous solution (ammonium carbonate is 9 grams) that pH is 9 is added in the aluminum sulfate aqueous solution that step 2) obtains under agitation condition, generate precipitation, centrifugal separation, dry, obtain aluminum ammonium carbonate; Said ammonium carbonate With step 2) the weight ratio control of described sediment (3 grams) is 3:1;

[0056] 4) Put the ammonium aluminum carbonate obtained in step 3) into an electric furnace, raise the temperature to 1200°C and keep it for 120 minutes for calcination, and cool to room temperature to prepare α-Al 2 o 3 Nano alumina material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com