Method for directly preparing stannic oxide nano-particles by using metallic tin

A technology of tin dioxide and nanoparticles, applied in the direction of tin oxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of polluting the environment, complexity, waste of resources and other post-processing processes, and avoid particle agglomeration , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

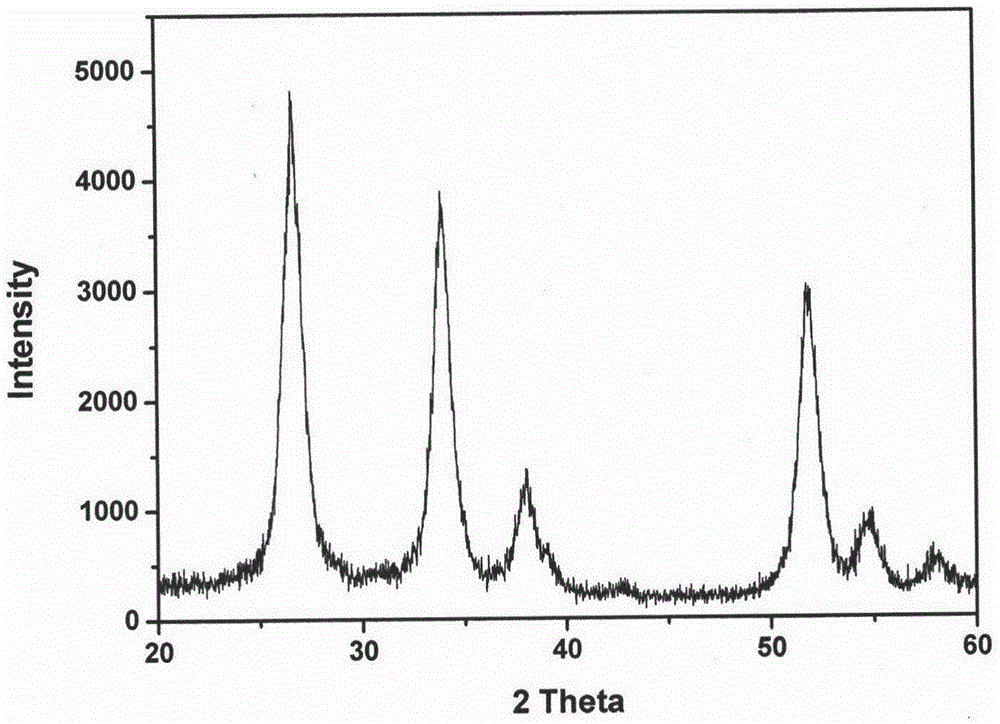

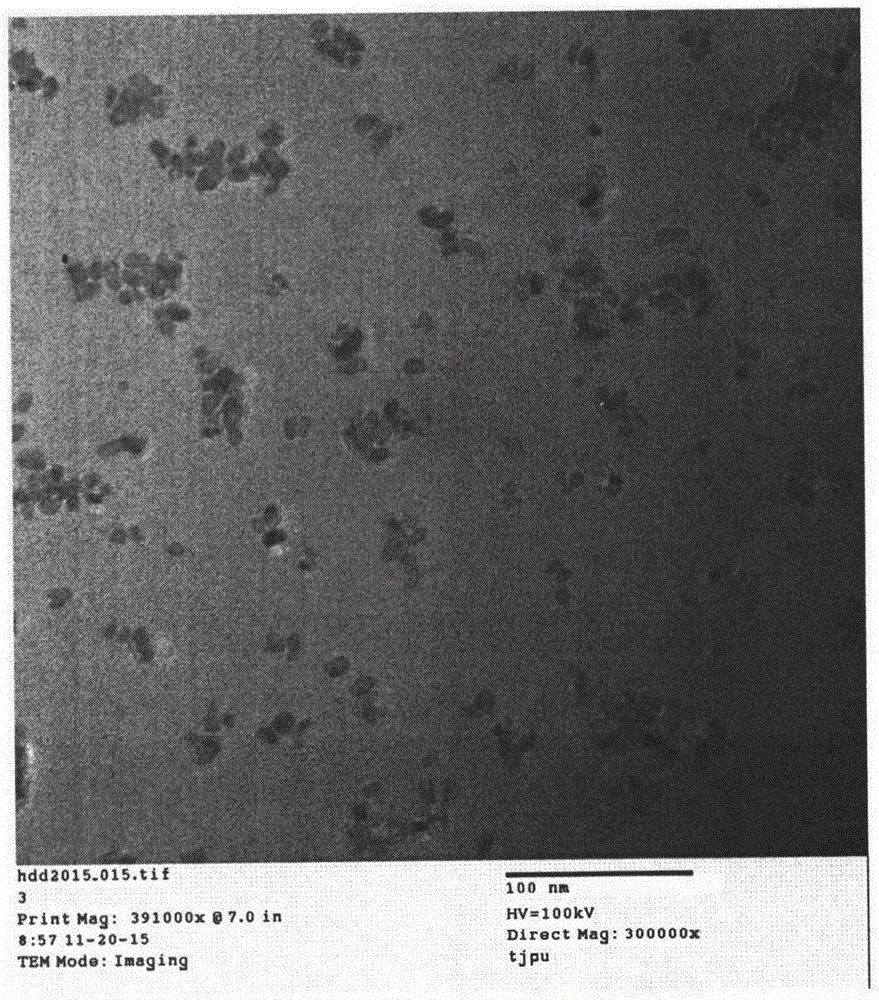

[0021] Dissolve 1.0 g of elemental iodine in 12.5 ml of absolute ethanol, and weigh 0.2 g of anhydrous sodium carbonate and dissolve it in 6.0 ml of deionized water; mix the above-mentioned iodine / ethanol solution with aqueous sodium carbonate solution, and add 0.4 g of tin powder of elemental metal , after continuous stirring, a reddish-brown mixed solution was obtained; the above mixed solution was quickly transferred to a stainless steel reactor to transfer all the tin powder into the reactor, reacted at 280°C for 3 days, cooled naturally to room temperature, and centrifuged to obtain The solid was washed with ethanol and deionized water successively, and dried to obtain tin dioxide nanoparticles with uniform particle size and good dispersion.

Embodiment 2

[0023] Dissolve 2.0 grams of iodine elemental substance in 8.0 milliliters of absolute ethanol, and weigh 0.8 grams of anhydrous sodium carbonate and dissolve it in 6.0 milliliters of deionized water; mix the above-mentioned iodine / ethanol solution with sodium carbonate aqueous solution, and add 0.6 grams of metal elemental tin powder , after continuous stirring, a reddish-brown mixed solution was obtained; the above mixed solution was quickly transferred to a stainless steel reactor to transfer all the tin powder into the reactor, reacted at 220°C for 1 day, cooled naturally to room temperature, and centrifuged to obtain The solid was washed successively with ethanol and deionized water, and dried to obtain tin dioxide nanoparticles.

Embodiment 3

[0025] Dissolve 0.65 grams of iodine elemental substance in 5.5 milliliters of absolute ethanol, and weigh 0.27 grams of anhydrous sodium carbonate and dissolve it in 5.5 milliliters of deionized water; mix the above-mentioned iodine / ethanol solution with sodium carbonate aqueous solution, and add 0.2 grams of metal elemental tin powder , after continuous stirring, a red-brown mixed solution was obtained; the above mixed solution was quickly transferred to a stainless steel reactor to transfer all the tin powder into the reactor, reacted at 200°C for 2 days, cooled naturally to room temperature, and centrifuged to obtain The solid was washed successively with ethanol and deionized water, and dried to obtain tin dioxide nanoparticles with good crystallinity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com