Preparation method of straw fermented biological fertilizer

A technology of fermenting organisms and fermenting raw materials, which is applied to the preparation of organic fertilizers, organic fertilizers, and fertilizer mixtures. It can solve the problems of inconvenient transportation and application of finished products, weak fertility of straw biological fertilizers, and cumbersome and complicated preparation processes. It achieves convenient transportation and The effect of application, strong fertility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

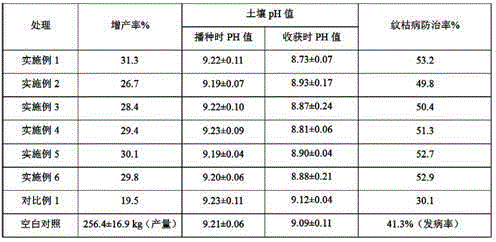

Examples

Embodiment 1

[0033] (1) Mix wheat straw, corn straw and reed straw at a weight ratio of 2:1:5, pulverize to 0.5 cm, and mix the pulverized straw mixture with water at a ratio of 4:1 to obtain fermentation raw materials;

[0034] (2) Inoculate the decomposed mixed bacteria in the fermented raw material according to the inoculum amount of 2% of the weight of the fermented raw material, sprinkle water to adjust the water content to 55%, and under the condition of heat preservation, compost and ferment for 12 days at 55°C to obtain the decomposed material; the decomposed mixed bacteria is obtained by The expansion culture solution of various bacteria is composed according to the following volume ratios: 22L of Oriental Yisa fermented bacteria solution, 3L of plant lactobacillus solution, 2.5L of Bacillus subtilis solution, 3L of Trichoderma viride solution, 1L of thermophilic Bacillus licheniformis solution and Candida utilis liquid 1L; during the fermentation period, turn over once every 2 day...

Embodiment 2

[0039] (1) Mix wheat straw, corn straw and reed straw in a weight ratio of 3:2:5, pulverize to 1 cm, and mix the pulverized straw mixture with water at a ratio of 5.5:1 to obtain fermentation raw materials;

[0040] (2) Inoculate the decomposed mixed bacteria in the fermented raw materials according to the inoculation amount of 0.5% of the weight of the fermented raw materials, sprinkle water to adjust the water content to 55%, and under the condition of heat preservation, compost and ferment for 7 days at 65°C to obtain the decomposed clinker; the decomposed mixed bacteria are obtained from The expansion culture solution of various bacteria is composed according to the following volume ratios: 25L of Oriental Yisa fermented bacterium liquid, 4L of plant Lactobacillus liquid, 2.5L of Bacillus subtilis liquid, 3L of Trichoderma viride liquid, 2L of thermophilic Bacillus licheniformis liquid and Candida utilis liquid 1.5L; during the fermentation period, turn over once every 2 da...

Embodiment 3

[0045] (1) Mix wheat straw, corn straw and reed straw at a weight ratio of 2:1:3, pulverize to 0.8 cm, and mix the pulverized straw mixture with water at a ratio of 3.5:1 to obtain fermentation raw materials;

[0046] (2) Inoculate the decomposed mixed bacteria in the fermented raw material according to the inoculation amount of 2% of the weight of the fermented raw material, sprinkle water to adjust the water content to 60%, and under the condition of heat preservation, compost and ferment for 15 days at 40°C to obtain the decomposed material; the decomposed mixed bacteria is obtained by The expansion culture solution of various bacteria is composed according to the following volume ratios: 15L of Oriental Yisa fermented bacteria solution, 2L of plant lactobacillus solution, 1.5L of Bacillus subtilis solution, 1L of Trichoderma viride solution, 1L of thermophilic Bacillus licheniformis solution and Candida utilis liquid 0.5L; during the fermentation period, turn over once ever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com