Polythioether sealant

A sealant and polysulfide technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as side group difficulties, and achieve increased crosslinking density, high yield, and rapid response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

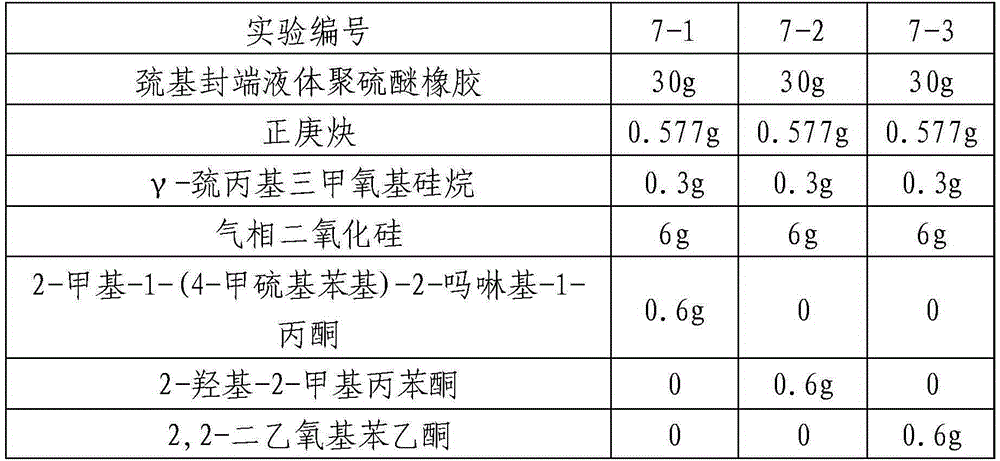

Examples

preparation example Construction

[0023] The preparation method of the above polysulfide sealant is as follows: Weigh the components of the polysulfide sealant in proportion, put them into a vacuum stirring device and stir for 10 minutes, then carry out vacuum stirring and mixing for at least 2 hours, and the vacuum pressure is not If it is greater than 20mbar, the sealant can be prepared and stored in a low-temperature shading seal.

[0024] The method of use is: apply the polysulfide sealant on the surface of the object to be sealed. These sealed objects can be metal plates, ceramic plates or organic plates, or braids of metal fibers or organic fibers. The curing method of the polysulfide sealant of the present invention is as follows: after coating, it can be irradiated with a light source for a certain period of time, and the light source can be natural light, a low-pressure mercury lamp, a medium-pressure mercury lamp or an LED ultraviolet lamp. Low-pressure mercury lamps are widely used, and the curing t...

Embodiment 1

[0025] Example 1: A polysulfide sealant containing pendant alkyl groups.

[0026] Mercapto-terminated liquid polysulfide rubber (30 g), n-heptyne (0.577 g, 0.006 mol), (2,4,6-trimethylbenzoyl) diphenylphosphine oxide (TPO) (0.6 g) , γ-mercaptopropyltrimethoxysilane (0.3g), and fumed silica (6g) were put into a 500mL three-neck round-bottomed flask, and stirred for 10min. Then reduce the pressure in the flask to 20mbar, and continue to stir for 2h. Afterwards, transfer the sealant product to an 80×50×2 steel abrasive tool, using a 365nm wavelength UV lamp 2200μW / cm 2 Cured for 2 minutes under the light intensity to obtain a rubber sheet. Prepare test pieces according to HB5246-1993, test performance in GB / T528-2009, use type 2 samples for tensile samples, measure the tensile strength, elongation at break and Shore hardness of the sealant after curing, see Table 1. Coat the mixed polysulfide sealant on the chromic acid anodized aluminum plate to form a thin layer of about 2mm...

Embodiment 2

[0027] Example 2: Polysulfide sealant containing side hydroxyl groups.

[0028] Mercapto-terminated liquid polysulfide rubber (30g), 6-heptynol (0.572g, 0.006mol), TPO (0.6g), γ-mercaptopropyltrimethoxysilane (0.3g), fumed silica (6g) was put into a 500mL round-bottomed three-neck flask, and stirred for 10min. Then reduce the pressure in the flask to 20mbar, and continue to stir for 2h. Afterwards, transfer the sealant product to an 80×50×2 steel abrasive tool, using a 365nm wavelength UV lamp 2200μW / cm 2Cured for 2 minutes under the light intensity to obtain a rubber sheet. Prepare test pieces according to HB5246-1993, test performance in GB / T528-2009, use type 2 samples for tensile samples, measure the tensile strength, elongation at break and Shore hardness of the sealant after curing, see Table 1. Coat the mixed polysulfide sealant on the chromic acid anodized aluminum plate to form a thin layer of about 2mm, and then cover it with a steel mesh. Cure for two minutes us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com