Water resistance metal binder and preparation method thereof

A technology of metal bonding and epoxy resin, applied in the direction of adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problems of low bonding strength, high cost, easy to fall off, etc. , to achieve the effect of easy industrial production, low production cost and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

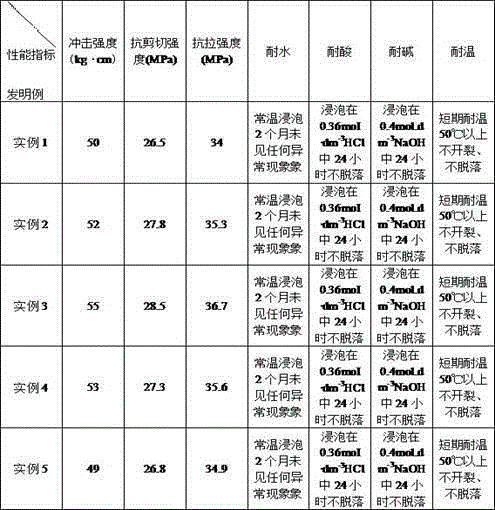

Embodiment 1

[0015] A water-resistant metal adhesive, comprising in parts by weight: 5 parts of methyltriethoxysilane, 5 parts of ethyl silicate, 30 parts of α-cyanoacrylate glue, 40 parts of bisphenol F epoxy resin, 20 parts of E-39 epoxy resin, 5 parts of p-hydroxybenzenesulfonic acid, 5 parts of hydroxyethyl cellulose, 5 parts of sodium alginate, 5 parts of cobalt boroacylate, 2 parts of nano titanium dioxide, 5 parts of barium sulfate, calcium lactate 2 parts, calcium citrate 2 parts, tetrapod zinc oxide whiskers 2-7 parts, ethanol 10-15 parts, dilute hydrochloric acid 2 parts, water 15 parts.

[0016] The preparation method of the above-mentioned water-resistant metal binder is as follows: first, stir methyltriethoxysilane, ethyl silicate and ethanol at 75°C, slowly add the above-mentioned mixed solution of dilute hydrochloric acid and water, and wait for the solution to be clarified; Add α-cyanoacrylate glue, bisphenol F epoxy resin, E-39 epoxy resin, hydroxyethyl cellulose, sodium a...

Embodiment 2

[0018] A water-resistant metal adhesive, comprising in parts by weight: 7 parts of methyltriethoxysilane, 7 parts of ethyl silicate, 35 parts of α-cyanoacrylate glue, 45 parts of bisphenol F epoxy resin, 22 parts of E-39 epoxy resin, 6 parts of p-hydroxybenzenesulfonic acid, 6 parts of hydroxyethyl cellulose, 6 parts of sodium alginate, 6 parts of cobalt boroacylate, 3 parts of nano titanium dioxide, 6 parts of barium sulfate, calcium lactate 3 parts, 3 parts of calcium citrate, 3 parts of tetraacicular zinc oxide whiskers, 11 parts of ethanol, 3 parts of dilute hydrochloric acid, 17 parts of water.

[0019] The preparation method of the above-mentioned water-resistant metal binder is as follows: first, stir methyltriethoxysilane, ethyl silicate and ethanol at 77°C, slowly add the above-mentioned mixed solution of dilute hydrochloric acid and water, and wait for the solution to be clarified; Add α-cyanoacrylate glue, bisphenol F epoxy resin, E-39 epoxy resin, hydroxyethyl cell...

Embodiment 3

[0021] A water-resistant metal adhesive, comprising in parts by weight: 9 parts of methyltriethoxysilane, 9 parts of ethyl silicate, 45 parts of α-cyanoacrylate glue, 55 parts of bisphenol F epoxy resin, 28 parts of E-39 epoxy resin, 9 parts of p-hydroxybenzenesulfonic acid, 9 parts of hydroxyethyl cellulose, 9 parts of sodium alginate, 9 parts of cobalt boroacylate, 4 parts of nano titanium dioxide, 9 parts of barium sulfate, calcium lactate 4 parts, 4 parts of calcium citrate, 6 parts of tetraacicular zinc oxide whiskers, 14 parts of ethanol, 4 parts of dilute hydrochloric acid, 23 parts of water.

[0022] The preparation method of the above-mentioned water-resistant metal binder is as follows: first, stir methyltriethoxysilane, ethyl silicate and ethanol at 82°C, slowly add the above-mentioned mixed solution of dilute hydrochloric acid and water, and wait for the solution to be clarified; Add α-cyanoacrylate glue, bisphenol F epoxy resin, E-39 epoxy resin, hydroxyethyl cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com