Chlorine-sulfur-phosphor-less high-extreme pressure fully synthetic cutting fluid and preparation method thereof

A fully synthetic, cutting fluid technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of metal corrosion, non-ferrous metal corrosion, environmental pollution, etc., achieve excellent lubricating extreme pressure, excellent anti-rust performance, long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

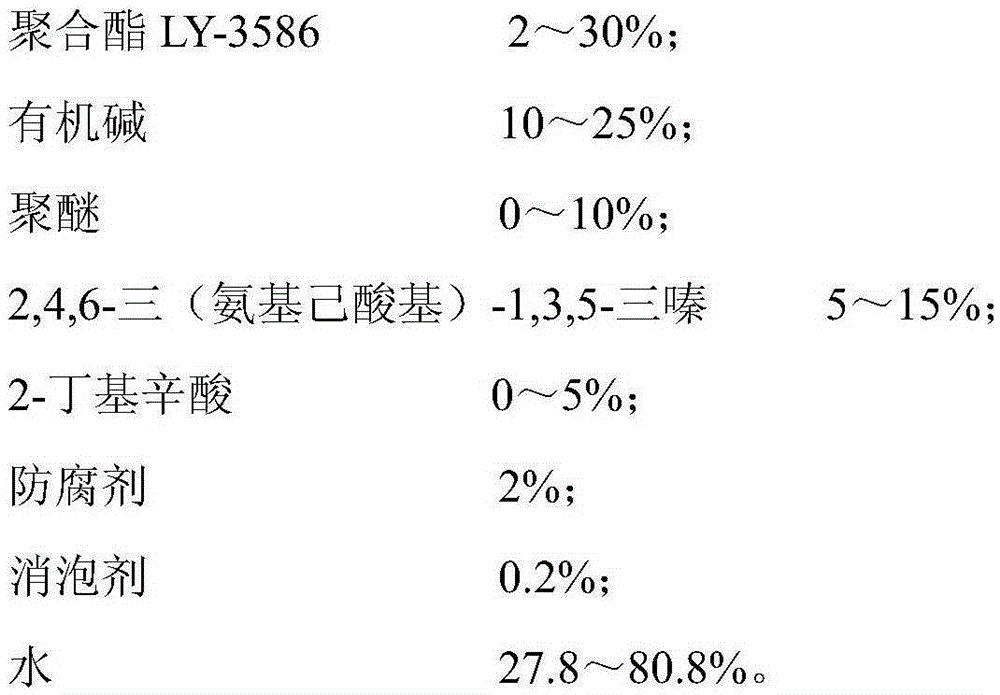

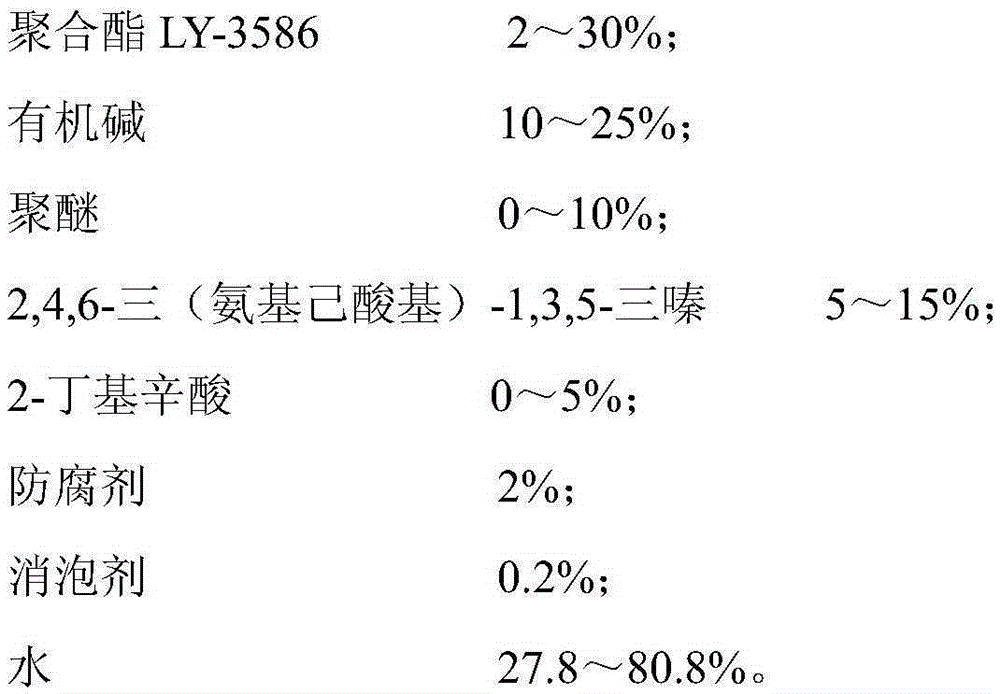

Method used

Image

Examples

Embodiment 1

[0033] In this example, a high extreme pressure fully synthetic cutting fluid free of chlorine, sulfur and phosphorus is prepared according to the following steps:

[0034] Weigh 100kg of organic base triethanolamine and 50kg of 2,4,6-tris(aminocaproic acid)-1,3,5-triazine into the mixing tank, heat up to 50°C, stir for 120min to dissolve and become transparent, and then add 20kg of polymer ester LY-3586, 20kg of preservatives (1kg of paraben, 17kg of s-triazine, 2kg of sodium dehydroacetate) and 2kg of defoamer TL-56N, stirred for 20min, finally added 808kg of water, stirred for 90min, filtered Promptly obtain a kind of chlorine, sulfur, phosphorus high extreme pressure fully synthetic cutting fluid, 6% aqueous solution has 0 level of rust resistance, and 5% aqueous solution has a maximum non-jamming load of 38 kg.

Embodiment 2

[0036] In this example, a high extreme pressure fully synthetic cutting fluid free of chlorine, sulfur and phosphorus is prepared according to the following steps:

[0037] Weigh 250kg of organic base triethanolamine and 150kg of 2,4,6-tris(aminocaproyl)-1,3,5-triazine into the mixing tank, heat up to 50°C, stir for 120min to dissolve and become transparent, and then add 178kg polymer ester LY-3586, 100kgEO / PO block polyether 1740, 20kg preservative (1kg paraben, 17kg s-triazine, 2kg dehydroacetate sodium) and 2kg defoamer TL-56N, stir for 20min, and finally Add 300kg of water, stir for 90 minutes, and filter to obtain a high extreme pressure fully synthetic cutting fluid that does not contain chlorine, sulfur, and phosphorus. The 1.5% aqueous solution has grade 0 rust resistance, and the 5% aqueous solution has a maximum non-jamming load of 132kg.

Embodiment 3

[0039] In this example, a high extreme pressure fully synthetic cutting fluid free of chlorine, sulfur and phosphorus is prepared according to the following steps:

[0040] Weigh 250kg of organic base triethanolamine, 50kg of 2-butyloctanoic acid and 100kg of 2,4,6-tris(aminocaproic acid)-1,3,5-triazine and add them into the stirring and mixing kettle, heat up to 50°C, and stir 120min to dissolve and become transparent, then add 150kg of polymer ester LY-3586, 50kg of EO / PO block polyether 1740, 20kg of preservatives (1kg of paraben, 17kg of s-triazine, 2kg of sodium dehydroacetate), 2kg of defoamer TL -56N, stir for 20min, finally add 378kg of water by weight, stir for 90min, and filter to get a high extreme pressure fully synthetic cutting fluid that does not contain chlorine, sulfur and phosphorus. No jamming load 109kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com