Washing resistant adhesive and preparation method thereof

An adhesive and water-resistant technology, used in the field of textile printing and dyeing auxiliaries, can solve the problems of reduced water resistance, peeling, poor storage performance, etc., and achieve the effect of reducing the water absorption rate of the film, improving water resistance, and low water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

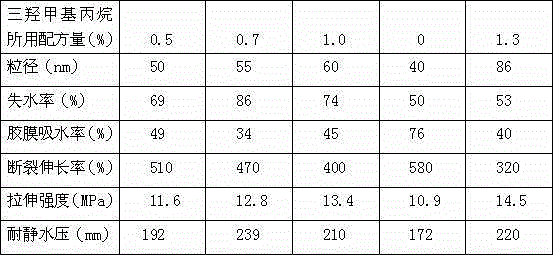

[0029] Table 1 is the test results of each parameter of the adhesive

[0030] Formulation amount of trimethylolpropane used (%) Particle size (nm) Water loss rate (%) Film water absorption (%) Elongation at break (%) Tensile strength (MPa) Hydrostatic pressure resistance (mm) 0.5 50 69 49 510 11.6 192

[0031] As can be seen from Table 1, 16 parts of organic solvent dimethylformamide, 30.5 parts of polyester polyol, 1 part of ethylene glycol, 1 part of 1.4 butanediol, and 0.1 part of antioxidant (SP-10) were put into the reactor , stirred at room temperature for 30 minutes to make it evenly mixed, added 2 parts of 4,4 xylylmethane diisocyanate, and then added 2 parts of 4,4 xylylmethane diisocyanate into the reaction kettle every half hour, 0.5 Add 2 parts of 4,4-xylylene diisocyanate and 0.05 parts of catalyst V-600 after 1 hour, then control the reaction temperature at 70°C, fully react for 2 hours, then add 15 parts of 2,4-xylylene diisocy...

Embodiment 2

[0033] Table 2 is the test results of each parameter of the adhesive

[0034] Formulation amount of trimethylolpropane used (%) Particle size (nm) Water loss rate (%) Film water absorption (%) Elongation at break (%) Tensile strength (MPa) Hydrostatic pressure resistance (mm) 0.7 55 86 34 470 12.8 239

[0035] As can be seen from Table 2, 24 parts of organic solvent dimethylformamide, 35 parts of polyester polyol, 2 parts of ethylene glycol, 10 parts of 1.4 butanediol, and 0.1 part of antioxidant (SP-10) were put into the reactor , stir at room temperature for 45 minutes to make it evenly mixed, add 2 parts of 4,4-xylylmethane diisocyanate, and then add 2 parts of 4,4-xylylmethane diisocyanate into the reaction kettle every half hour, 0.5 Add 2 parts of 4,4 xylylene diisocyanate and 0.06 parts of catalyst V-600 after 1 hour, and then control the reaction temperature at 70°C, and fully react for 2 hours, then add 15 parts of 2,4 toluene diisoc...

Embodiment 3

[0037] Table 3 is the test results of each parameter of the adhesive

[0038] Formulation amount of trimethylolpropane used (%) Particle size (nm) Water loss rate (%) Film water absorption (%) Elongation at break (%) Tensile strength (MPa) Hydrostatic pressure resistance (mm) 1.0 60 74 45 400 13.4 210

[0039] As can be seen from Table 3, 24 parts of organic solvent dimethylformamide, 35 parts of polyester polyol, 2.5 parts of ethylene glycol, 12 parts of 1.4 butanediol, and 0.3 parts of antioxidant (SP-10) were put into the reactor , stirred at room temperature for 60 minutes to make it evenly mixed, added 2 parts of 4,4 xylylmethane diisocyanate, and then added 2 parts of 4,4 xylylmethane diisocyanate into the reaction kettle every half hour, 0.5 Add 2 parts of 4,4 xylylene diisocyanate and 0.06 parts of catalyst V-600 after 1 hour, then control the reaction temperature at 75°C, and fully react for 2 hours, then add 15 parts of 2,4 toluene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com