Industrial waste heat utilization system adopting supercritical carbon dioxide working medium

A technology of industrial waste heat and carbon dioxide, applied in the field of waste heat utilization, can solve the problems of high investment cost and low utilization efficiency of industrial waste heat, and achieve the effect of reducing investment cost, shortening investment recovery period and improving economic competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

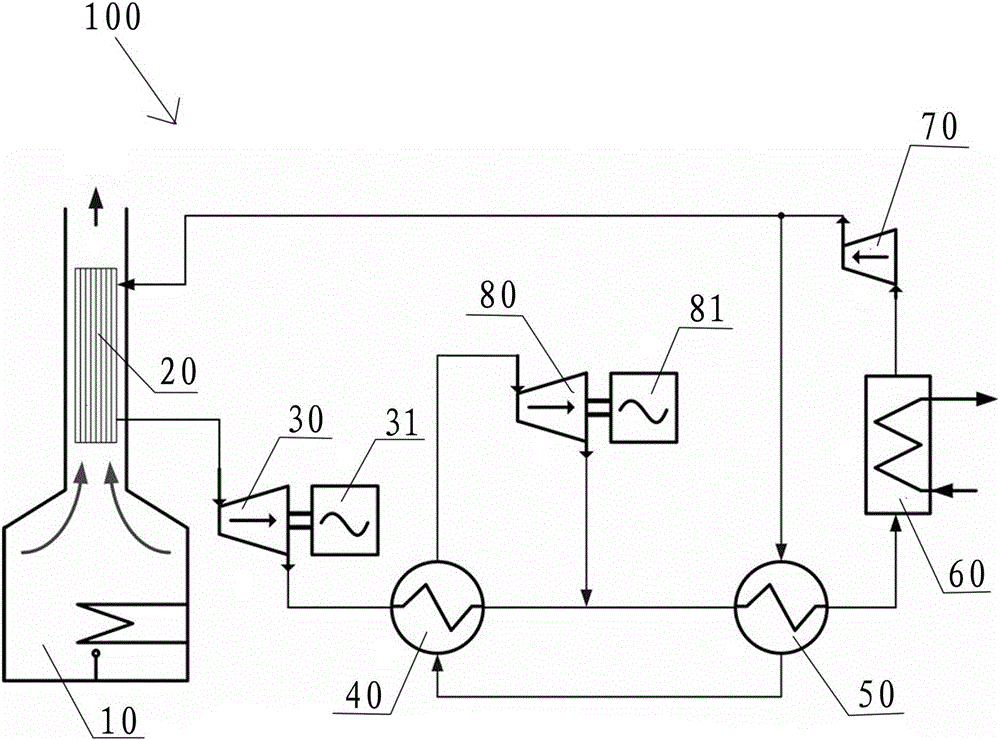

[0022] see figure 1 , the industrial waste heat utilization system 100 shown in the preferred embodiment of the present invention includes a main process heat source 10, a flue gas heat exchanger 20, a first turbine 30, a first generator 31, a first regenerator 40, a second Regenerator 50 , cooler 60 , compressor 70 , second turbine 80 and second generator 81 .

[0023] The main process heat source 10 is a variety of industrial equipment capable of generating industrial waste heat, such as heating furnaces or heating equipment used in various industries, more specifically thermal power plant boilers, diesel engines, gas turbines, converters, coke ovens, etc.

[0024] The flue gas heat exchanger 20 is arranged in the main process heat source 10, and the gas or liquid with industrial waste heat generated by the main process heat source 10 enters from the primary side inlet of the flue gas heat exchanger 20 and After heat exchange in the flue gas heat exchanger 20 , it is discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com