Mixed paint for composite membrane of lithium ion battery, composite membrane and preparation method thereof, and lithium ion battery

A technology for lithium-ion batteries and composite diaphragms, applied in secondary batteries, battery pack components, circuits, etc., can solve the problem of insufficient blockage of polyolefin micropores, incomplete cutting of lithium ion transmission channels, and increased equipment and production costs and other problems to achieve the effect of avoiding curling, continuous coating process and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

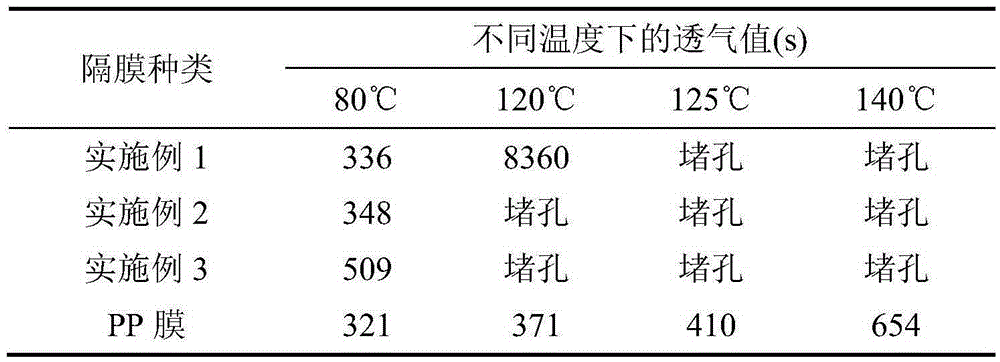

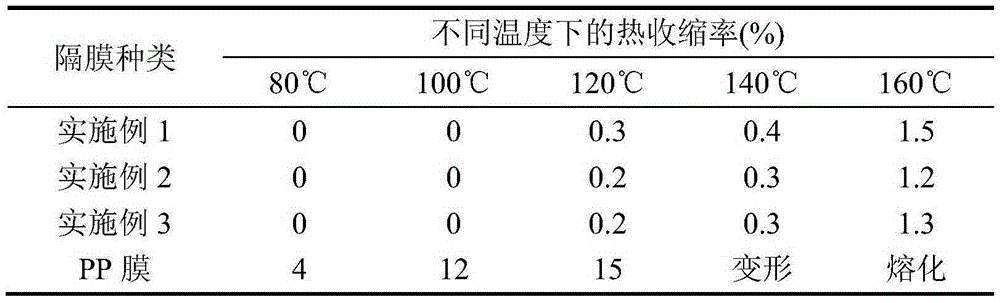

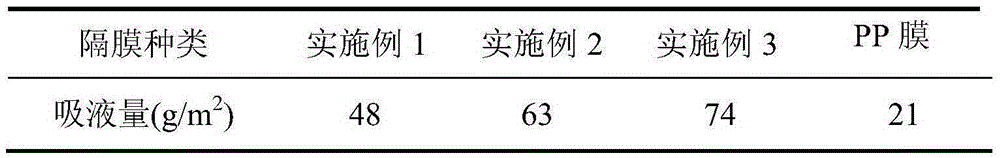

Embodiment 1

[0040] The mixed coating for lithium ion battery composite separator in the present embodiment comprises the component of following parts by weight: the particle diameter of 90 parts is the styrene-divinylbenzene copolymer (PS base) microsphere of 0.7 μm, 95 parts of Al with a particle size of 0.5 μm 2 o 3 Particles, 15 parts of binder, the binder includes the first binder and the second binder, the first binder is 10 parts of PVA, the second binder is 5 parts of CMC, styrene- The melting point or softening point temperature of the divinylbenzene copolymer microspheres is lower than the thermal melting temperature of the base film used in the lithium-ion battery separator.

[0041] The lithium-ion battery composite diaphragm in the present embodiment comprises a base film and a mixed paint layer coated on one side of the base film, and the mixed paint layer includes the following components in parts by weight: 95 parts with a particle diameter of 0.7 μm styrene-divinylbenzen...

Embodiment 2

[0054] The mixed coating for the lithium-ion battery composite separator in the present embodiment comprises the following components in parts by weight: 93 parts of acrylonitrile-acrylate copolymer microspheres with a particle diameter of 0.7 μm, and 92 parts with a particle diameter of 0.9 μm SiO 2 Particles, 15 parts of binder, the binder includes the first binder and the second binder, the first binder is 7 parts of LA132, the second binder is 8 parts of PVDF, acrylonitrile- The melting point or softening point temperature of the acrylate copolymer microspheres is lower than the thermal melting temperature of the base film used in the lithium-ion battery separator.

[0055] The lithium-ion battery composite separator in this embodiment includes a base film and a mixed paint layer coated on both sides of the base film, and the mixed paint layer includes the following components in parts by weight: 93 parts with a particle diameter of 0.7 μm acrylonitrile-acrylate copolymer...

Embodiment 3

[0064] The mixed coating for lithium-ion battery composite diaphragm in the present embodiment comprises the component of following parts by weight: the particle diameter of 90 parts is the ethylene-vinyl acetate copolymer (EVA) microsphere of 0.7 μ m, the particle diameter of 93 parts 1.0μm TiO 2 Granules, 15 parts of binder, the binder includes the first binder and the second binder, the first binder is 10 parts of LA132, the second binder is 7 parts of PVDF, ethylene-acetic acid The melting point or softening point temperature of the vinyl ester copolymer microspheres is lower than the thermal melting temperature of the base film used in the lithium-ion battery separator.

[0065] The lithium-ion battery composite diaphragm in the present embodiment comprises a base film and a mixed paint layer coated on both sides of the base film, and the mixed paint layer includes the following components in parts by weight: 90 parts with a particle diameter of 0.7 μm ethylene-vinyl ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com