Mechanochemistry recycling method of waste lithium battery cathode material

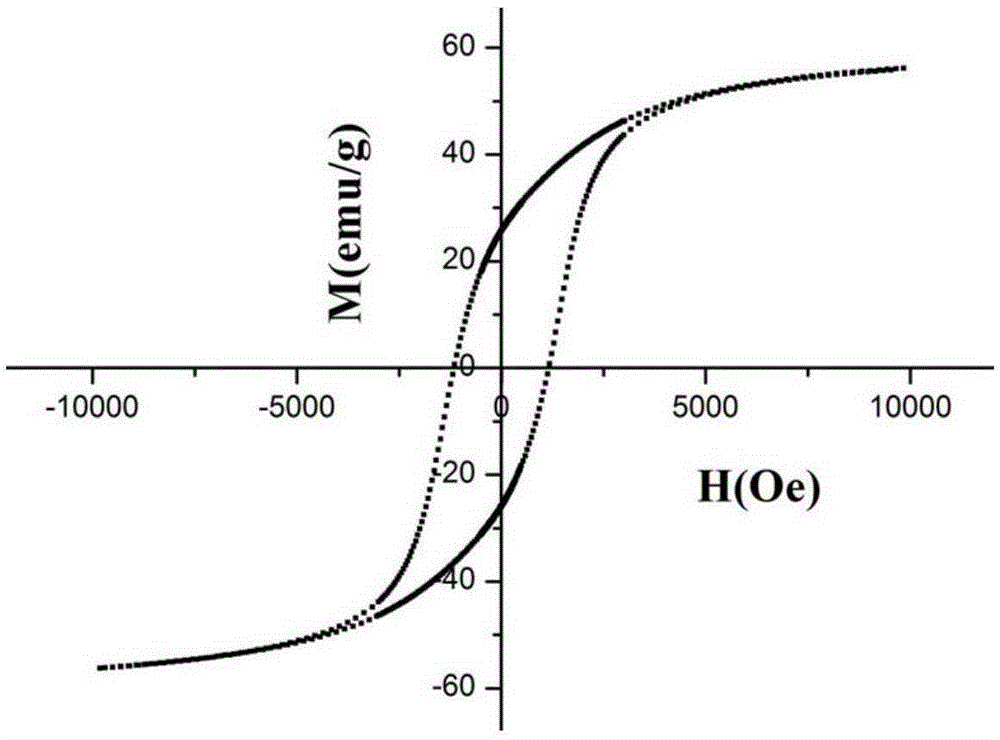

A technology for waste lithium batteries and positive electrode materials, which is applied in the field of mechanochemical recycling of waste lithium battery positive electrode materials, can solve the problems of difficult disposal of subsequent waste liquid, loss of metal resources, large environmental load, etc., and achieves low cost, excellent magnetic properties, The effect of reducing recovery costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for mechanochemical recycling of waste lithium battery cathode materials, specifically comprising the following steps:

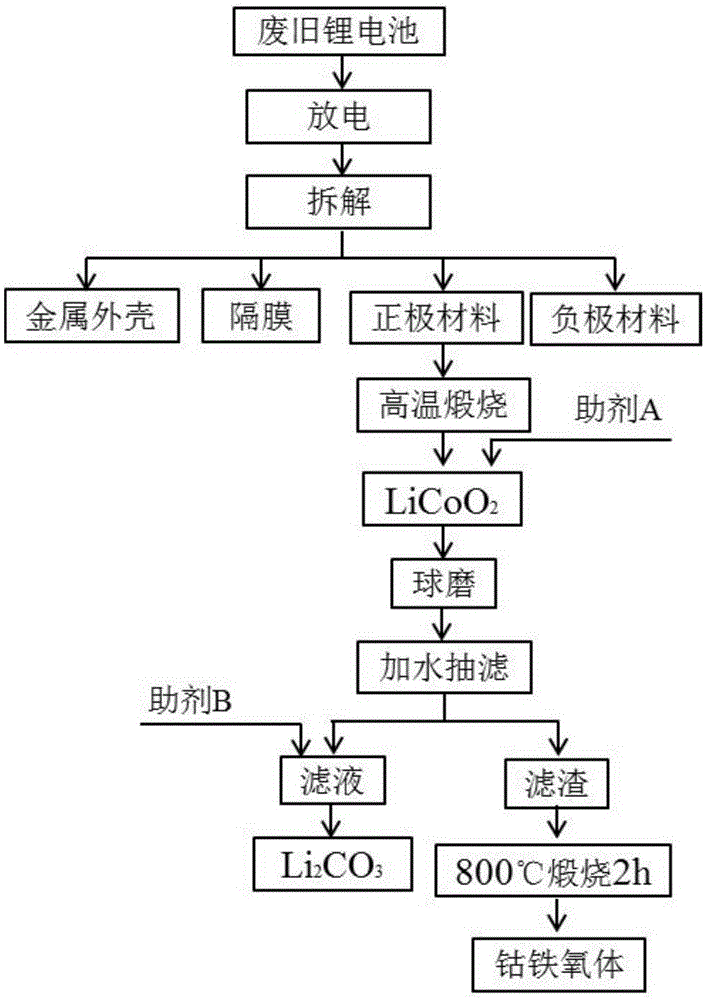

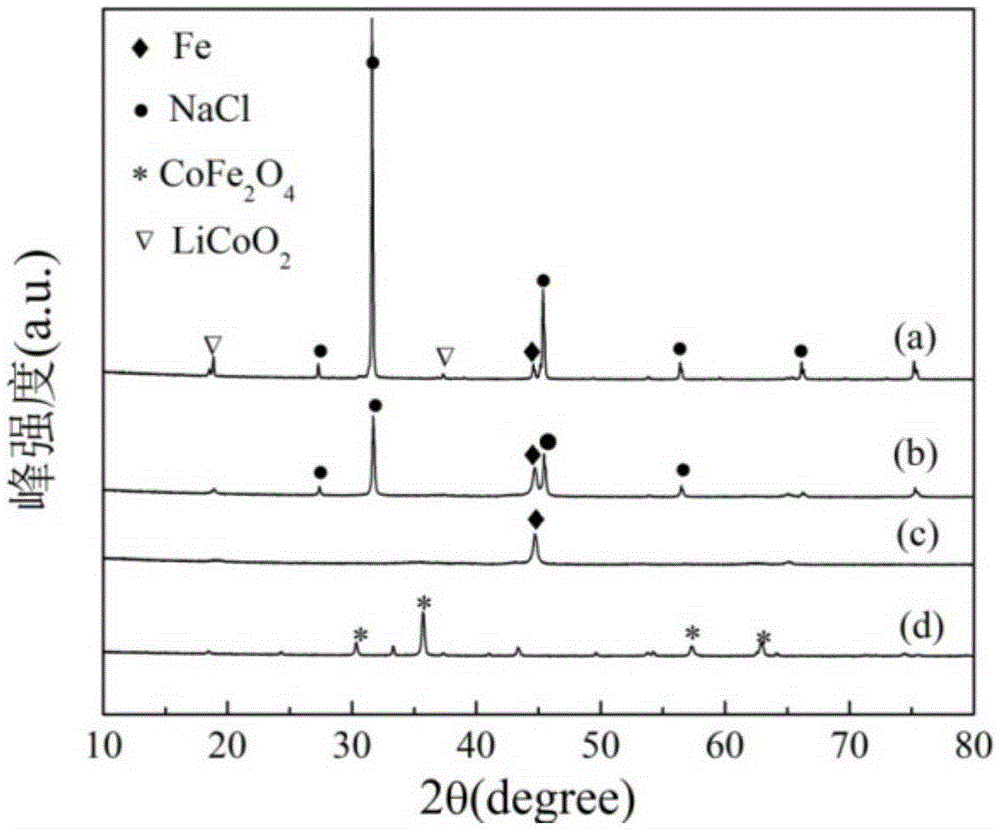

[0026] according to figure 1 Flowchart, take the waste lithium battery, disassemble to get the metal case, organic separator, positive electrode material and negative electrode material. The positive electrode material is calcined at high temperature and sieved to obtain LiCoO 2 powder. Weigh 1.0gLiCoO 2 Powder, by LiCoO 2 , Fe powder and NaCl with a mass ratio of 1:2.5:5, put them into a ball mill tank after mixing, weigh stainless steel balls according to the ball-to-material ratio of 80:1 and place them in the tank, and use an elastic O-shaped ball between the ball mill tank and the ball mill cover. ring seal. Set the ball milling speed to 600 rpm, and the ball milling time to 12 hours. After the ball milling, rinse the balls and the milling tank with 50 mL of deionized water, and then use a vacuum filtration device to separate the f...

Embodiment 2

[0028] A method for mechanochemical recycling of waste lithium battery cathode materials, specifically comprising the following steps:

[0029] according to figure 1 Flow chart, take waste mobile phone lithium battery, disassemble to get metal case, organic separator, positive electrode material and negative electrode material. The positive electrode material is calcined at high temperature and sieved to obtain LiCoO 2 powder. Weigh 10gLiCoO 2 Powder, LiCoO 2 , Fe powder and NaCl are mixed at a mass ratio of 1:2.5:5, put into a ball mill tank after mixing, weigh stainless steel balls according to the ball-to-material ratio of 50:1 and place them in the tank, and use elastic O-shaped balls between the ball mill tank and the ball mill cover. ring seal. Set the ball milling speed to 600 rpm, and the ball milling time to 15 hours. After the ball milling, rinse the balls and the milling tank with 500 mL of deionized water, and then use a vacuum filtration device to separate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com