Integral Propeller Intelligent Grinding System

A grinding and propeller technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of high technical requirements of relief grinding workers, low overall propeller production efficiency, and difficulty in ensuring processing quality. To achieve the effect of simple and flexible grinding process, overcoming easy and rapid wear and eliminating occupational hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing. Embodiments of the present invention include, but are not limited to, the following examples.

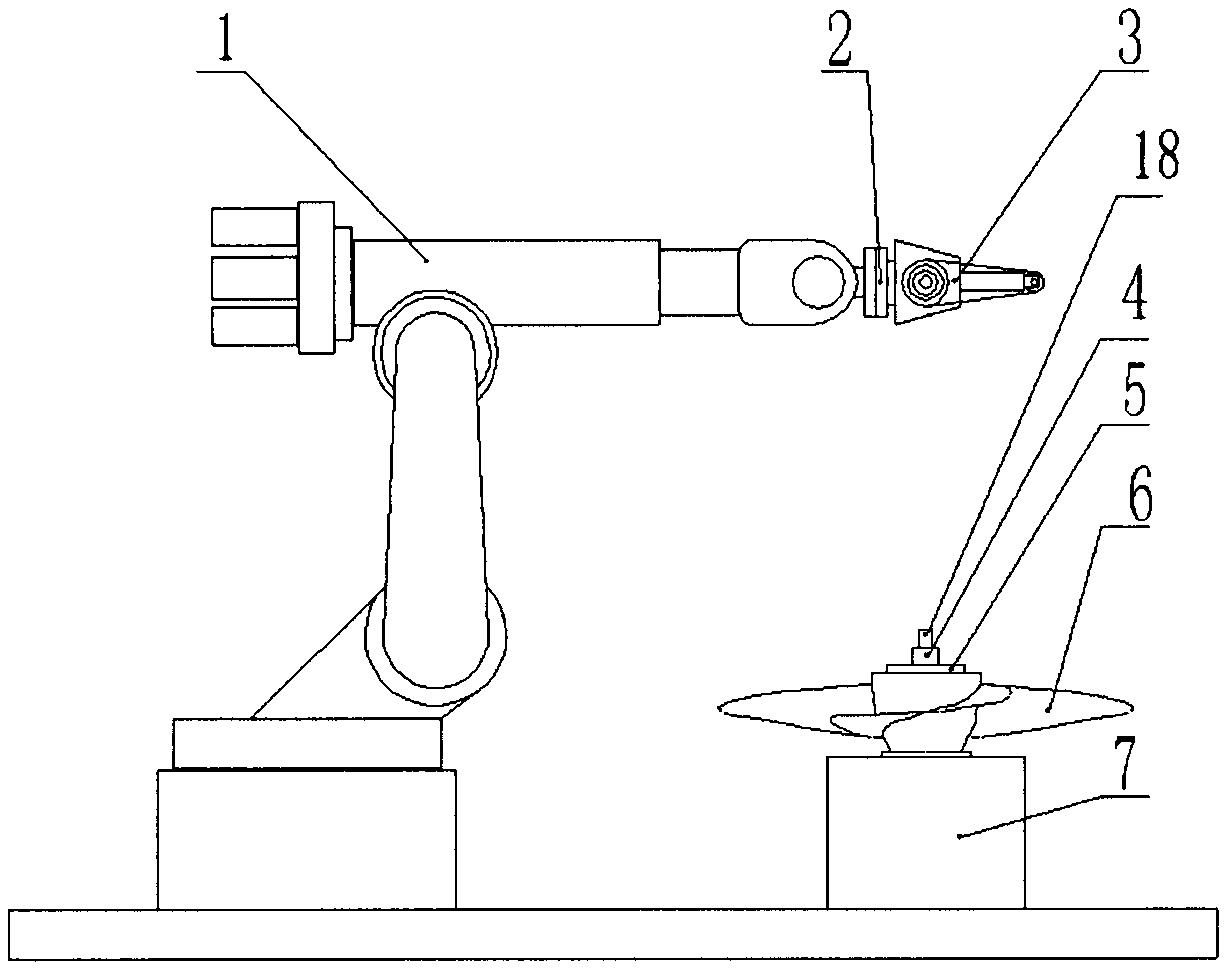

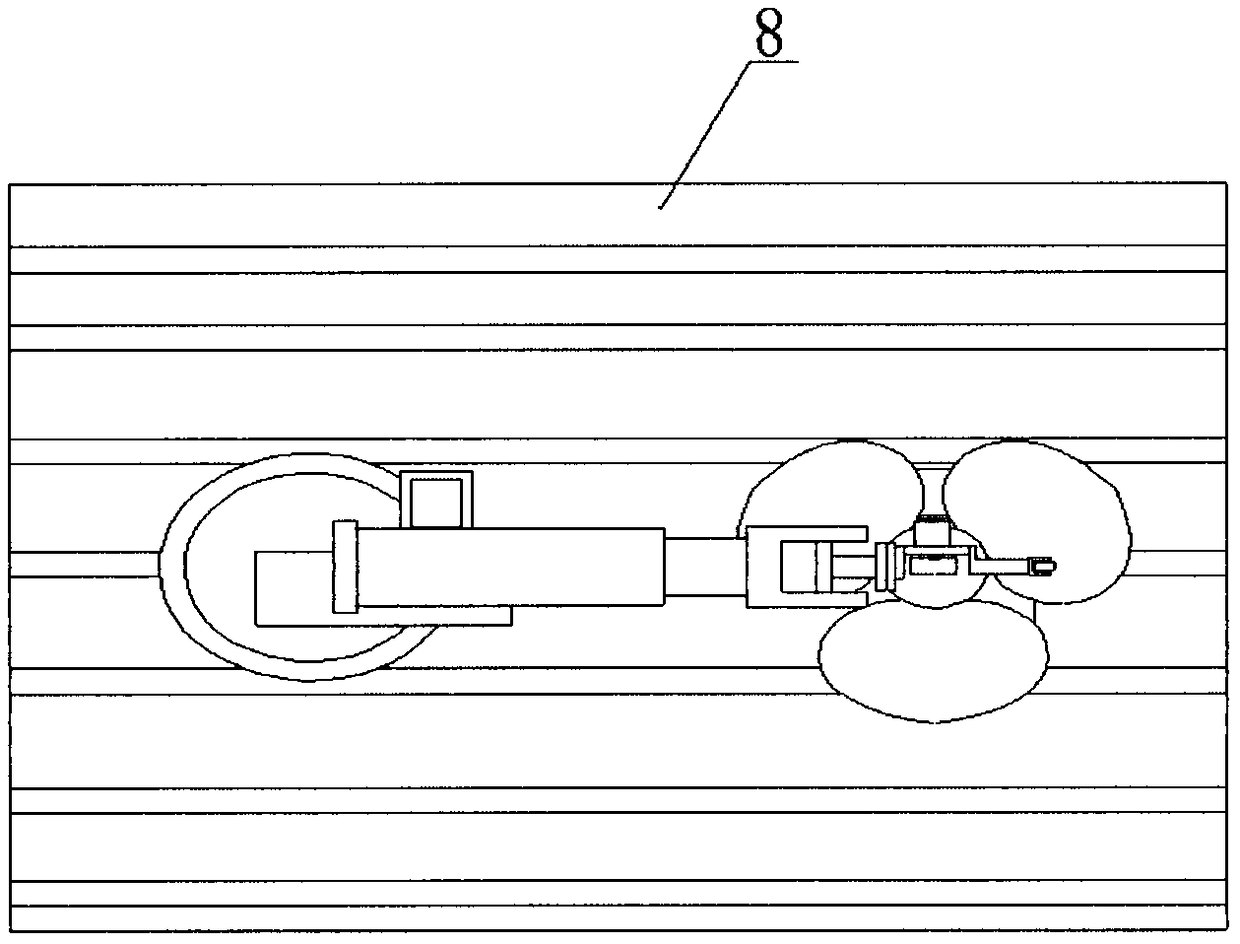

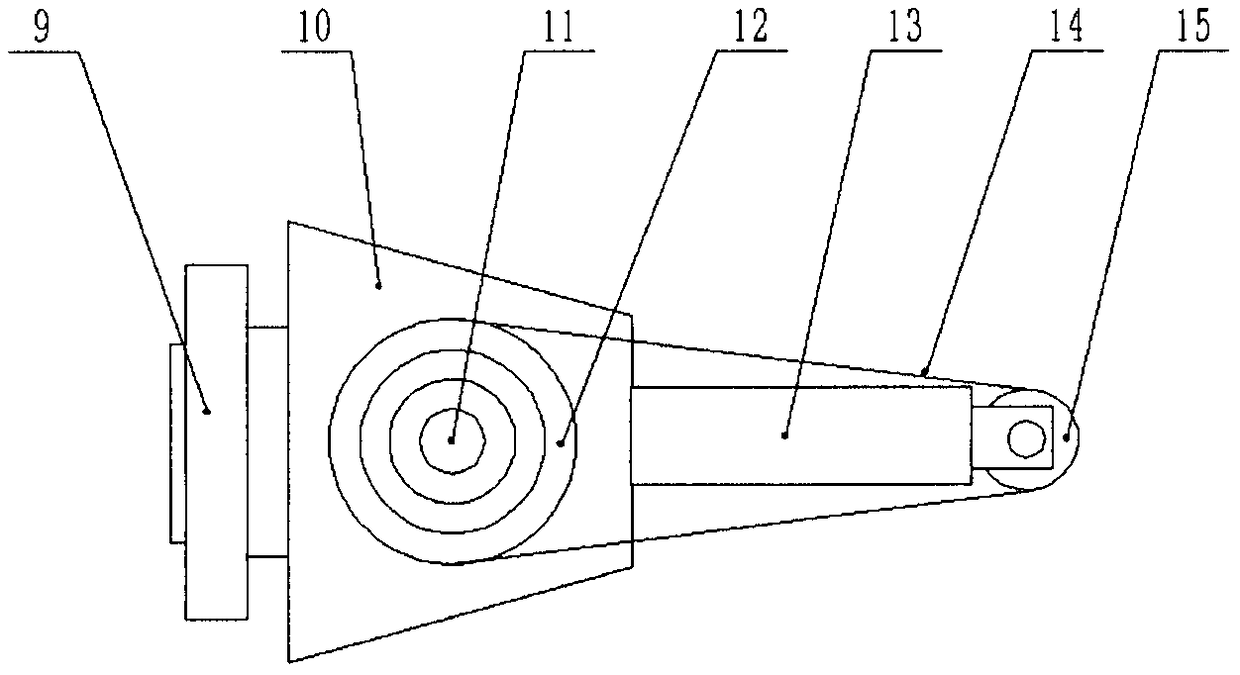

[0041] Such as figure 1 , figure 2 As shown, it is a front view and a top view of the main structure of a preferred example of the integrated propeller intelligent grinding system and method of the present invention. A mature six-axis industrial robot 1 is installed in the confined space formed by the combined aluminum alloy glass house 19, and the workpiece support platform 7 arranged within the working space of the six-axis industrial robot is arranged and fixed on a T-shaped slot plate, and the integral propeller The blank workpiece 6 is set on the end surface of the workpiece support table through the clamping guide column 18, and the pressure plate 5 fixes the whole propeller blank workpiece through the clamping action of the lock nut 4 on the clamping guide column, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com