A kind of anti-icing coating, its preparation method and application

An anti-icing and coating technology, which is applied in the field of coatings, can solve the problems of good adhesion between the coating and the substrate, good anti-icing durability, and large water contact angle of the coating, so as to achieve anti-wear, strong anti-icing, and reduce icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

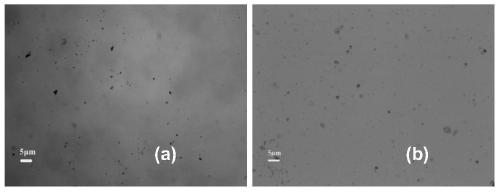

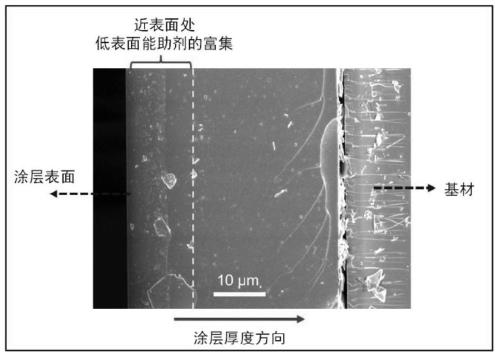

Image

Examples

preparation example Construction

[0061] Correspondingly, a kind of preparation method of anti-icing paint, comprises the following steps:

[0062] S01. Weigh each component according to the formula of the above-mentioned anti-icing coating;

[0063] S02. Use a diluent to dissolve the hydroxyacrylic resin to obtain a hydroxyacrylic resin system;

[0064] S03. Adding a silane coupling agent, a silicon-containing low surface energy additive, a surface modification additive and other additives to the hydroxyl acrylic resin system sequentially under mixing treatment conditions, and obtaining the component A system after mixing and dispersing treatment;

[0065] S04. The component A system is mixed with the component B fatty acid isocyanate to obtain an anti-icing coating.

[0066] Specifically, in the above step S01, the preferred formula and content of the anti-icing coating have been described above, and will not be repeated here.

[0067] In above-mentioned step S02, described diluent adopts containing xylene...

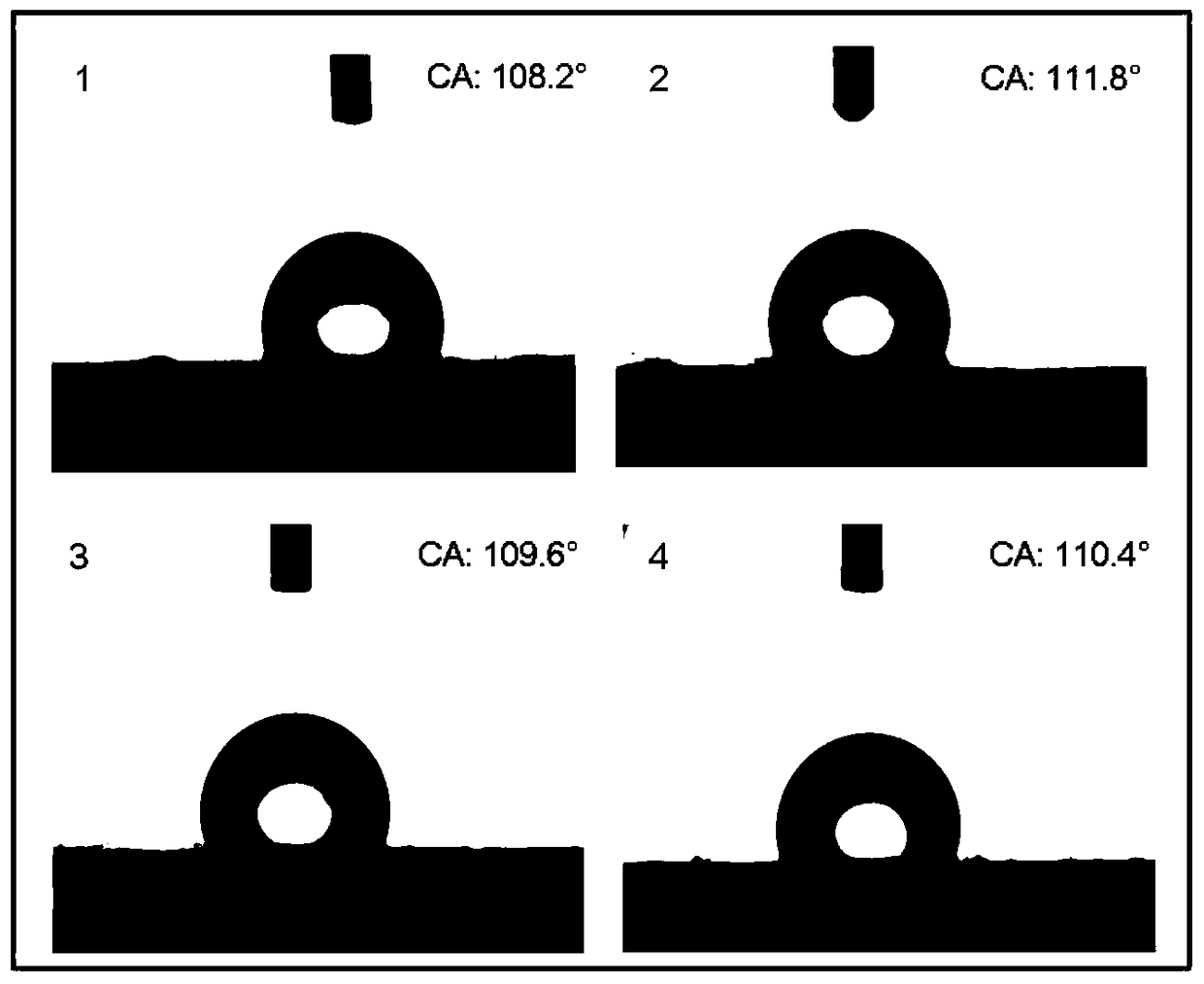

Embodiment 1

[0075] An anti-icing coating, its formulation components and their contents are shown in Table 1, Example 1, wherein the silicon-containing low surface energy auxiliary agent is LancoTMGlidd 4370, and the surface modification auxiliary agent is polyethylene wax powder , the leveling agent is polyether modified polydimethylsiloxane, the defoamer is Deqian 6800, the aliphatic isocyanate is HDI trimer, the light stabilizer is TINUVIN1130, the The hindered amine is TINUVIN123.

[0076] The preparation method of described anti-icing coating, comprises the following steps:

[0077] S11. Weigh each component according to the formula of the above-mentioned anti-icing coating;

[0078] S12. Use a diluent to dissolve the hydroxyacrylic resin to obtain a hydroxyacrylic resin system, wherein the diluent contains xylene, butyl acetate and aromatic solvent naphtha S100 # , PMA, cyclohexanone, MAK, MEK, ethyl acetate and DBE mixed solvent;

Embodiment 2

[0082] An anti-icing coating, its formulation components and their contents are shown in Table 1, Example 2, wherein the silicon-containing low surface energy auxiliary agent is LancoTMGlidd 4365, and the surface modification auxiliary agent is polyethylene wax slurry , the leveling agent is silicone modified polyacrylate, the defoamer is Deqian 7800, the aliphatic isocyanate is HDI trimer, the light stabilizer is TINUVIN1130, and the hindered amine is TINUVIN123.

[0083] The preparation method of described anti-icing coating, comprises the following steps:

[0084] S21. Weigh each component according to the formula of the above-mentioned anti-icing coating;

[0085] S22. Use a diluent to dissolve the hydroxyacrylic resin to obtain a hydroxyacrylic resin system, wherein the diluent contains xylene, butyl acetate and aromatic solvent naphtha S100 # , PMA, cyclohexanone, MAK, MEK, ethyl acetate and DBE mixed solvent;

[0086] S23. Add silane coupling agent, silicon-containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com