Room-temperature-cured fluorine-silicone coating containing fluorinated cage-shaped silsesquioxane and preparation method and application

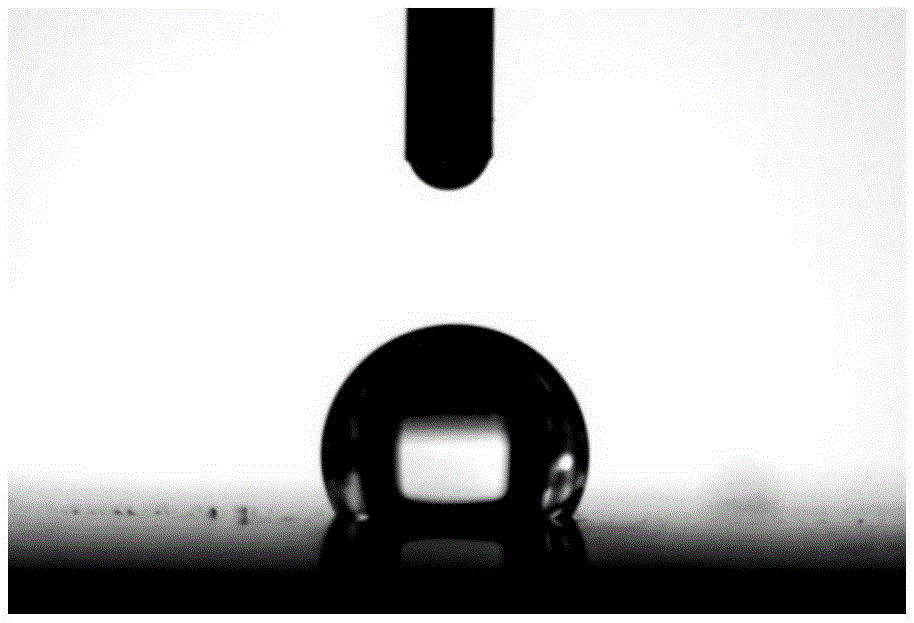

A technology of silsesquioxane and silsesquioxane, which is applied in the direction of coatings and silicon organic compounds, and can solve the problems of reducing the ice adhesion strength of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

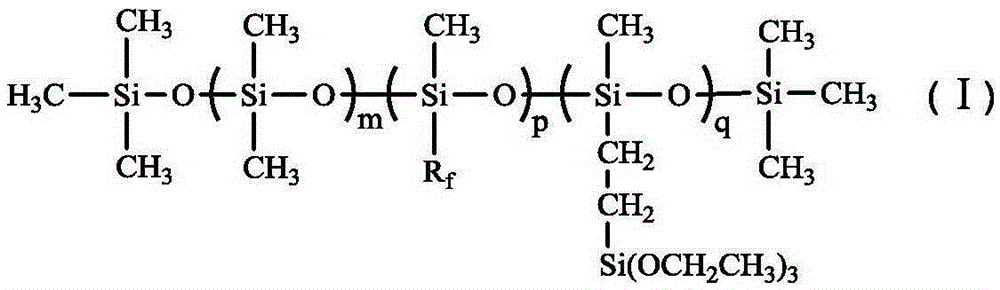

[0033] (1) Preparation of fluorosilicone resin. Dissolve 1.5g of hydrogen-containing silicone oil (hydrogen content 0.75wt%, molecular weight 2000g / mol) and 0.8g of hexafluorobutyl methacrylate (the molar ratio of Si-H to C=C is 1:0.3) in 9.2g In trifluorotoluene, 0.23 mg of chloroplatinic acid catalyst was added under the protection of nitrogen, the temperature was raised to 80° C., and the reaction was stirred for 6 h, then 1.7 g of vinyltriethoxysilane was added into the reaction system, and the reaction was continued for 12 h. After the reaction, the crude product was rotary evaporated to remove the solvent, and dried in a vacuum oven at 40°C for one day to remove the residual solvent and unreacted monomer to obtain the target product, whose structural formula is:

[0034]

[0035] In the formula, m=10, p / q=0.4, p=5.

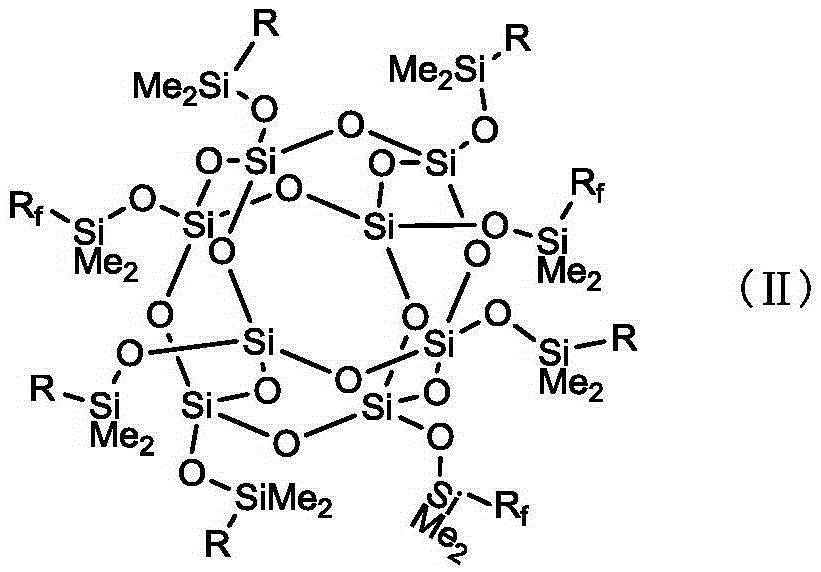

[0036] (2) Preparation of fluorinated cage silsesquioxane. Dissolve 0.5 g of dimethylsilyl cage silsesquioxane in 2.0 g of anhydrous toluene, and add 0...

Embodiment 2

[0040] (1) Preparation of fluorosilicone resin. Dissolve 1.5g of hydrogen-containing silicone oil (hydrogen content 0.75wt%, molecular weight 2000g / mol) and 2.7g of dodecafluoroheptyl methacrylate (the molar ratio of Si-H to C=C is 1:0.6) in 16.8 In g trifluorotoluene, 0.42 mg of chloroplatinic acid catalyst was added under the protection of nitrogen, the temperature was raised to 80° C., and the reaction was stirred for 12 h, then 1.1 g of vinyltriethoxysilane was added to the reaction system, and the reaction was continued for 10 h. After the reaction, the crude product was rotary evaporated to remove the solvent, and dried in a vacuum oven at 40°C for one day to remove the residual solvent and unreacted monomer to obtain the target product, whose structural formula is:

[0041]

[0042] In the formula, m=10, p / q=2, p=10.

[0043] (2) Preparation of fluorinated cage silsesquioxane. Dissolve 0.5g of dimethylsilyl cage silsesquioxane in 2.0g of anhydrous toluene, add 0.59...

Embodiment 3

[0047] (1) Preparation of fluorosilicone resin. Dissolve 1.5g of hydrogen-containing silicone oil (hydrogen content 0.75wt%, molecular weight 2000g / mol) and 4.4g of trifluorooctyl methacrylate (the molar ratio of Si-H to C=C is 1:0.9) in 23.6 In g trifluorotoluene, 0.59 mg of chloroplatinic acid catalyst was added under the protection of nitrogen, the temperature was raised to 80° C., and the reaction was stirred for 14 hours, then 0.4 g of vinyltriethoxysilane was added to the reaction system, and the reaction was continued for 8 hours. After the reaction, the crude product was rotary evaporated to remove the solvent, and dried in a vacuum oven at 40°C for one day to remove the residual solvent and unreacted monomer to obtain the target product, whose structural formula is:

[0048]

[0049] In the formula, m=10, p / q=9, p=14.

[0050] (2) Preparation of fluorinated cage silsesquioxane. Dissolve 0.5g of dimethylsilyl cage silsesquioxane in 2.0g of anhydrous toluene, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

| Ice shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com