Biological feed and preparation method thereof

A bio-feed and bio-fermentation technology, applied in animal feed, animal feed, applications, etc., can solve the problems of complex raw material components, high cost, and unstable content of effective components, and achieve simple operation, simple production, and easy scale The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

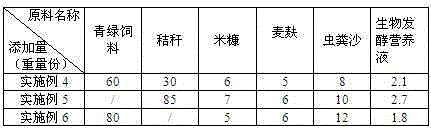

Embodiment 1

[0037] A biological feed, comprising the following raw materials by weight: 80 parts of green feed and straw plant material with a weight ratio of 3:1; 5 parts of rice bran; 5 parts of wheat bran, 10 parts of insect excrement sand, and 2.0 parts of biological fermentation nutrient solution The biological fermentation nutrient solution is composed of the following raw materials in parts by weight: 5 parts of corn distiller's dregs, 5 parts of sorghum distiller's dregs, 7.5 parts of wheat bran, 0.5 part of distiller's yeast, 7 parts of edible fungus waste base material, and 0.10 parts of microbial bacterial agent Parts, 75 parts of brewery waste liquor, pH is 6.8.

[0038] The microbial bacterial agent includes Bacillus subtilis, Bacillus, lactic acid bacteria, yeast and filamentous fungi, and the total number of live bacteria is more than or equal to 20 billion / g.

[0039] The brewing waste is corn distiller's dregs and sorghum distiller's dregs with a mass ratio of 1:1, which ...

Embodiment 2

[0057] A biological feed, comprising the following raw materials by weight: 90 parts of green feed; 7 parts of rice bran, 5 parts of wheat bran, 12 parts of insect excrement sand; 1.5 parts of biological fermentation nutrient solution, the biological fermentation nutrient solution consists of the following parts by weight Composition of raw materials: 12 parts of corn brewing waste residue, 10 parts of wheat bran, 0.8 part of distiller's yeast, 9 parts of edible fungus waste base material, 0.15 parts of microbial agent, 100 parts of brewing waste liquid, pH 6.5.

[0058] The microbial bacterial agent includes Bacillus subtilis, Bacillus, lactic acid bacteria, yeast and filamentous fungi, and the total number of live bacteria is more than or equal to 20 billion / g.

[0059] The corn brewing waste residue is distiller's grains produced after brewing liquor with corn as the main raw material.

[0060] The edible fungus waste base material is to use cottonseed husks as the main raw...

Embodiment 3

[0071] A biological feed, comprising the following raw materials in parts by weight: 85 parts by weight of straw; 5 parts of rice bran, 8 parts of wheat bran, 15 parts of insect excrement sand; 3.0 parts of biological fermentation nutrient solution, the biological fermentation nutrient solution consists of the following parts by weight Raw material composition: 5 parts of corn distiller's residue, 8 parts of sorghum distiller's dregs, 12 parts of wheat bran, 0.6 part of distiller's yeast, 8 parts of edible fungus waste base material, 0.12 parts of microbial agent, 74 parts of brewing waste liquid, pH 7.0.

[0072] The microbial bacterial agent includes Bacillus subtilis, Bacillus, lactic acid bacteria, yeast and filamentous fungi, and the total number of live bacteria is more than or equal to 20 billion / g.

[0073] The brewing waste is corn distiller's dregs and / or sorghum distiller's dregs, which are distiller's grains produced after brewing liquor with corn / sorghum as the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com