Nanometer-ZnO-loaded expanded vermiculite adsorbing material and preparation method thereof

A technology of expanded vermiculite and adsorbent materials, which is applied in chemical instruments and methods, adsorbed water/sewage treatment, and other chemical processes, etc., can solve the problems of general adsorption capacity, poor heat resistance, volatile, etc., and achieves human safety and non-toxicity. , good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

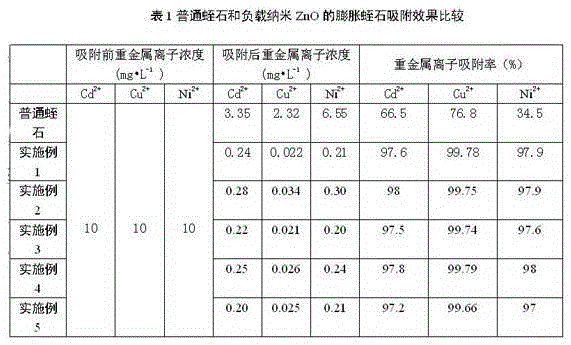

Examples

Embodiment 1

[0031] A preparation method of an expanded vermiculite adsorption material loaded with nanometer ZnO, comprising the following steps:

[0032] (1), zinc acetate dihydrate Zn(Ac) 2 2H 2 O, dissolved in ethanol, forms Zn(Ac) 2 2H 2 0 ethanol solution, add polyethylene glycol equimolar with zinc ion, obtain dihydrate zinc acetate mixed solution;

[0033] (2), adding expanded vermiculite to zinc acetate dihydrate mixed solution and stirring evenly, the ratio of zinc acetate dihydrate to expanded vermiculite is 20mmol / g, to obtain zinc acetate mixed solution with zinc acetate concentration of 0.4-0.8mol / L, Then add the oxalic acid ethanol solution dropwise into the zinc acetate mixed solution, adjust the pH value of the zinc acetate mixed solution to 6-10 with sodium hydroxide ethanol solution, and then place it in a constant temperature water bath at 60-90°C and stir for 0.5-4h After filtration, the gel is obtained;

[0034] (3) Wash the gel twice, heat at 80-110°C for 0.4-1h...

Embodiment 2

[0038] A preparation method of an expanded vermiculite adsorption material loaded with nanometer ZnO, comprising the following steps:

[0039] (1), zinc acetate dihydrate Zn(Ac) 2 2H 2 O, dissolved in ethanol, forms Zn(Ac) 2 2H 2 0 ethanol solution, add polyethylene glycol equimolar with zinc ion, obtain dihydrate zinc acetate mixed solution;

[0040] (2), adding expanded vermiculite to zinc acetate dihydrate mixed solution and stirring evenly, the ratio of zinc acetate dihydrate to expanded vermiculite is 4mmol / g, to obtain a zinc acetate mixed solution with a zinc acetate concentration of 0.4-0.8mol / L, Then add the oxalic acid ethanol solution dropwise into the zinc acetate mixed solution, adjust the pH value of the zinc acetate mixed solution to 6-10 with sodium hydroxide ethanol solution, and then place it in a constant temperature water bath at 60-90°C and stir for 0.5-4h After filtration, the gel is obtained;

[0041] (3) After washing the gel twice, heating at 80-1...

Embodiment 3

[0045] A preparation method of an expanded vermiculite adsorption material loaded with nanometer ZnO, comprising the following steps:

[0046] (1), zinc acetate dihydrate Zn(Ac) 2 2H 2 O, dissolved in ethanol, forms Zn(Ac) 2 2H 2 0 ethanol solution, add polyethylene glycol equimolar with zinc ion, obtain dihydrate zinc acetate mixed solution;

[0047] (2), adding the expanded vermiculite to the zinc acetate dihydrate mixed solution and stirring evenly, the ratio of zinc acetate dihydrate to the expanded vermiculite is 40mmol / g, to obtain a zinc acetate mixed solution with a zinc acetate concentration of 0.4-0.8mol / L, Then add the oxalic acid ethanol solution dropwise into the zinc acetate mixed solution, the molar ratio of oxalic acid and zinc acetate dihydrate is 1:1-1:5, adjust the pH value of the zinc acetate mixed solution to 6-10 with sodium hydroxide ethanol solution , and then placed in a constant temperature water bath at 60-90°C, stirred and reacted for 0.5-4h, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com