Improved preparation method of nitenpyram

A kind of technology of nitenpyram and ethylamine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

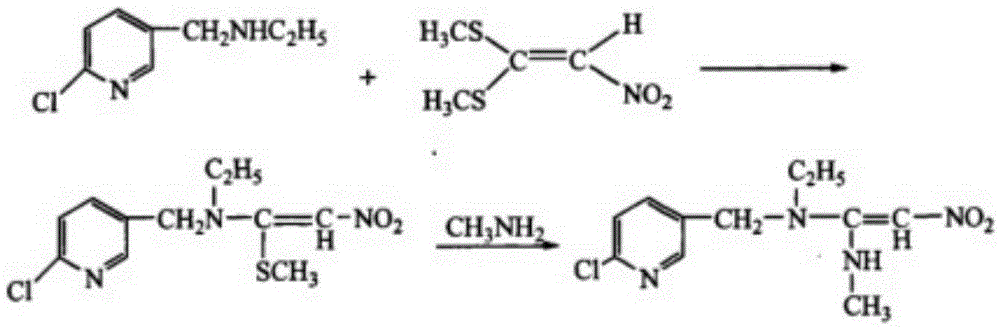

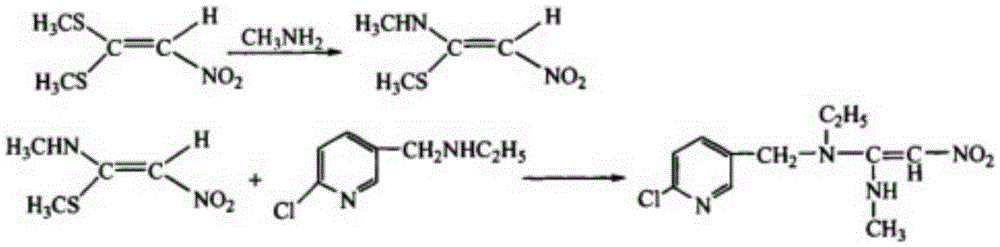

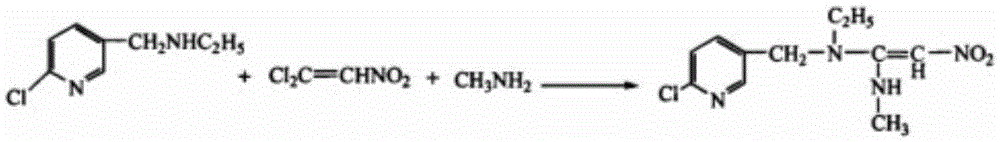

Method used

Image

Examples

Embodiment 1

[0040] Preparation of compound (b) 1,1,1-trichloro-2-nitroethane

[0041] 1. In a 5000L glass-lined reactor, add 2231kg of 36% hydrochloric acid, cool below 10°C, add 978kg of sodium nitrate in batches, stir for 20min, and then add 3kg of tetrabutylammonium bromide;

[0042] 2. Add 970kg of vinylidene chloride dropwise, control the temperature at 10°C, and keep warm for 4 hours after the addition;

[0043] 3. After the reaction is completed, stand still for 30 minutes and separate into layers;

[0044] 4. Add 1000kg of tap water to the organic layer and stir for 30min, then stand still for 30min to separate the layers to obtain 1606.5kg of compound (b) 1,1,1-trichloro-2-nitroethane, GC=90%, molar yield 0.9;

[0045] Preparation of compound (c) 1,1-dichloro-2-nitroethylene

[0046] 1. In a 5000L glass-lined kettle, add 1606.5kg of the obtained compound (b), add 1000kg of tap water, and raise the temperature by 30-40°C;

[0047] 2. Then add 2100kg 8% NaHCO dropwise 3 About...

Embodiment 2

[0068] Preparation of compound (b) 1,1,1-trichloro-2-nitroethane

[0069] 1. In a 5000L glass-lined reactor, add 2231kg of 36% hydrochloric acid, cool below 10°C, add 978kg of sodium nitrate in batches, stir for 20min, and then add 3kg of tetrabutylammonium bromide;

[0070] 2. Add 970kg of vinylidene chloride dropwise, control the temperature at 20°C, and keep warm for 3 hours after the addition;

[0071] 3. After the reaction is completed, stand still for 30 minutes and separate into layers;

[0072] 4. Add 1000kg of tap water to the organic layer and stir for 30min, then stand still for 30min to separate the layers to obtain 1606.5kg of compound (b) 1,1,1-trichloro-2-nitroethane, GC=90%, molar yield 0.9;

[0073] Preparation of compound (c) 1,1-dichloro-2-nitroethylene

[0074] 1. In a 5000L glass-lined kettle, add 1606.5kg of the obtained compound (b), add 1000kg of tap water, and raise the temperature by 30-40°C;

[0075] 2. Then add 2100kg 8% NaHCO dropwise 3 About...

Embodiment 3

[0096] Preparation of compound (b) 1,1,1-trichloro-2-nitroethane

[0097] 1. In a 5000L glass-lined reactor, add 2231kg of 36% hydrochloric acid, cool below 10°C, add 978kg of sodium nitrate in batches, stir for 20min, and then add 3kg of tetrabutylammonium bromide;

[0098] 2. Add 970kg of vinylidene chloride dropwise, control the temperature at 25°C, and keep warm for 3 hours after the addition;

[0099] 3. After the reaction is completed, stand still for 30 minutes and separate into layers;

[0100] 4. Add 1000kg of tap water to the organic layer and stir for 30min, then stand still for 30min to separate the layers to obtain 1606.5kg of compound (b) 1,1,1-trichloro-2-nitroethane, GC=90%, molar yield 0.9;

[0101] Preparation of compound (c) 1,1-dichloro-2-nitroethylene

[0102] 1. In a 5000L glass-lined kettle, add 1606.5kg of the obtained compound (b), add 1000kg of tap water, and raise the temperature by 30-40°C;

[0103] 2. Then add 2100kg 8% NaHCO dropwise 3 About...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com